Arc detection method for slab casting machine based on holographic method

The technology of a slab continuous casting machine and a detection method, which is applied in the directions of measuring devices, instruments, and optical devices, can solve the problems of error accumulation, low precision, and complicated methods, and achieve the effect of improving efficiency and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

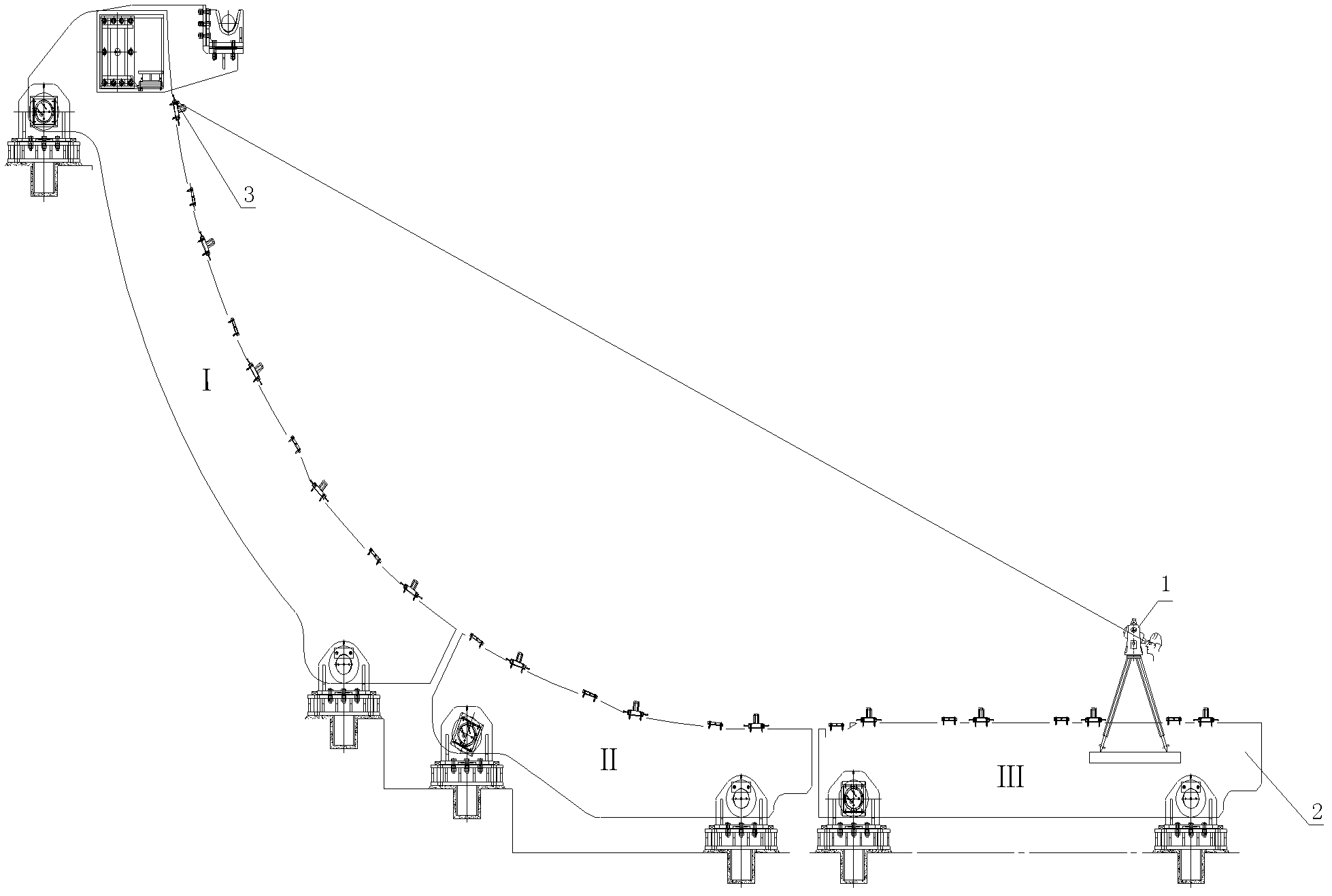

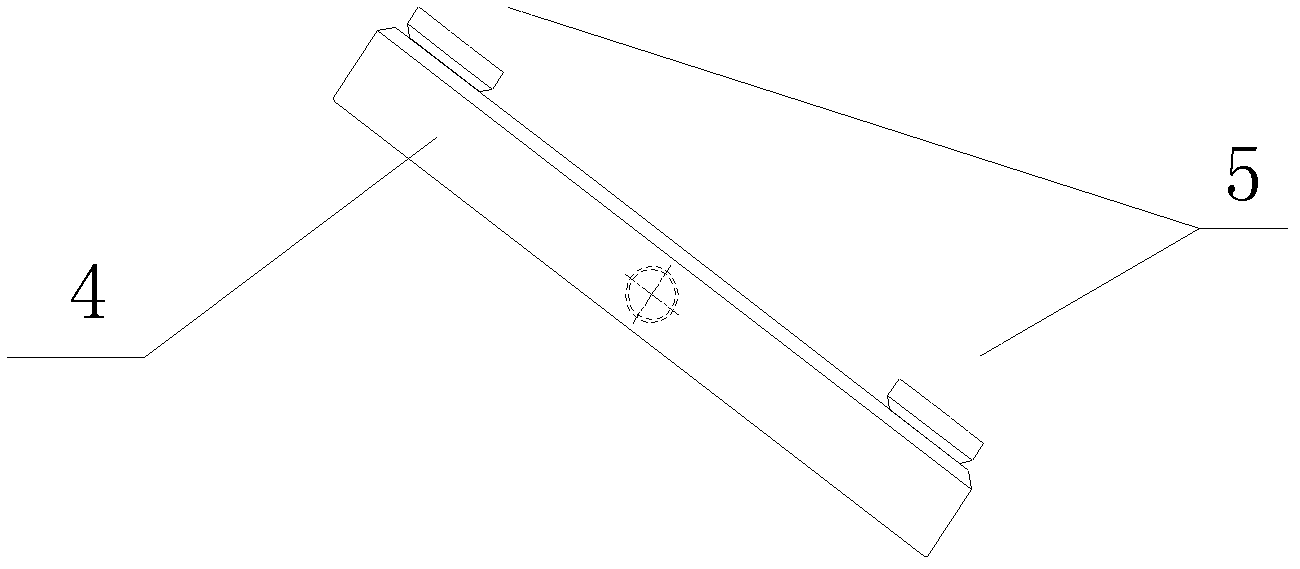

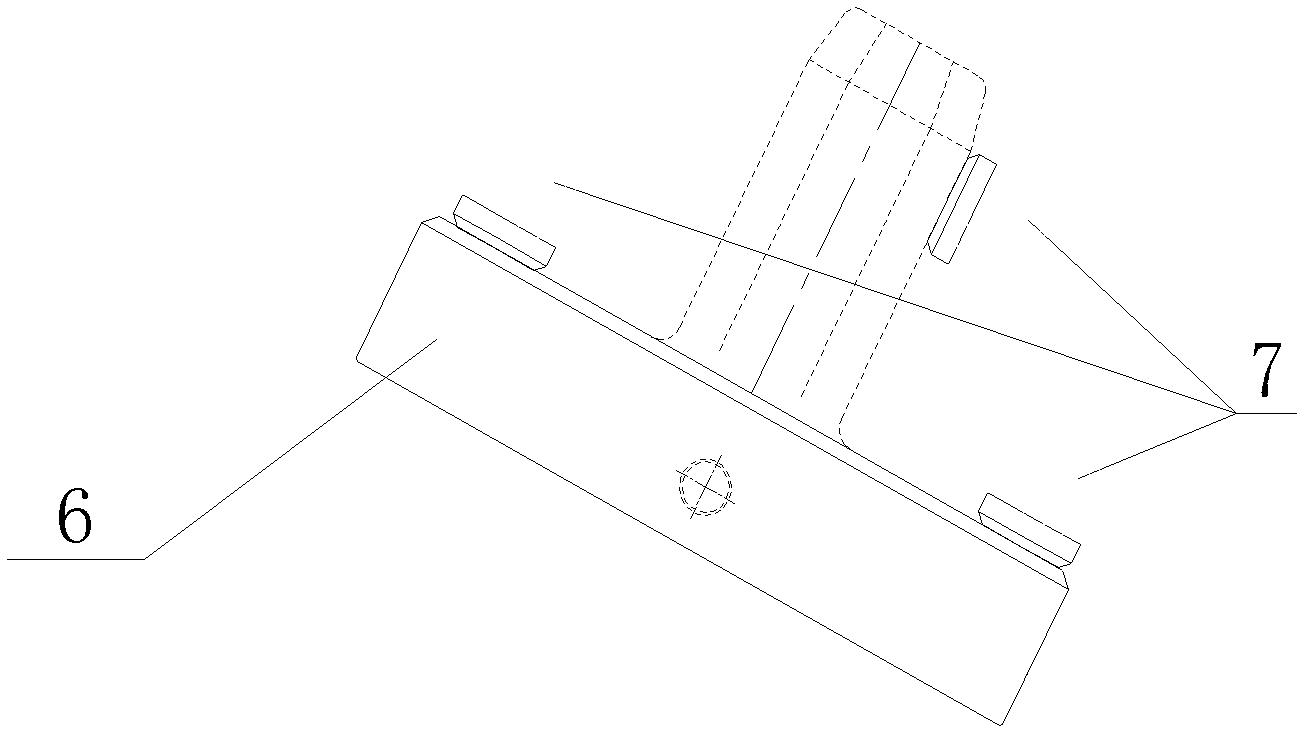

[0021] Figure 1~5 It is an embodiment of the present invention.

[0022] The implementation steps are:

[0023] (1) Instrument station and sampling point

[0024] Set up the total station in the middle of the horizontal section III of the support frame of the fan section (such as figure 1 shown), and ensure that the instrument can observe all sector supports; figure 2 shown), flat pin support (such as image 3 shown), round pin support (such as Figure 4 Shown), to collect points;

[0025] (2) Coordinate system conversion

[0026] The origin of the coordinate system actually measured coincides with the origin of the coordinate system in the computer model, and then the Z axis of the coordinate system measured and fitted is converted into the Y axis in the computer model, that is, the coordinate points (X, Z) of the fitted coordinate system are measured. ) value into the (X, Y) value in the computer model;

[0027] (3) Coordinate acquisition and position simulation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com