Alcohol-water separation recycling device of fischer-tropsch synthesis water

A technology of alcohol-water separation and Fischer-Tropsch synthesis, applied in the fields of environmental protection and resource utilization, can solve the problems of high energy consumption, inability to make full use of organic raw materials, etc., and achieves reduced operating energy consumption, good environmental protection and economy, and significant environmental benefits. and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

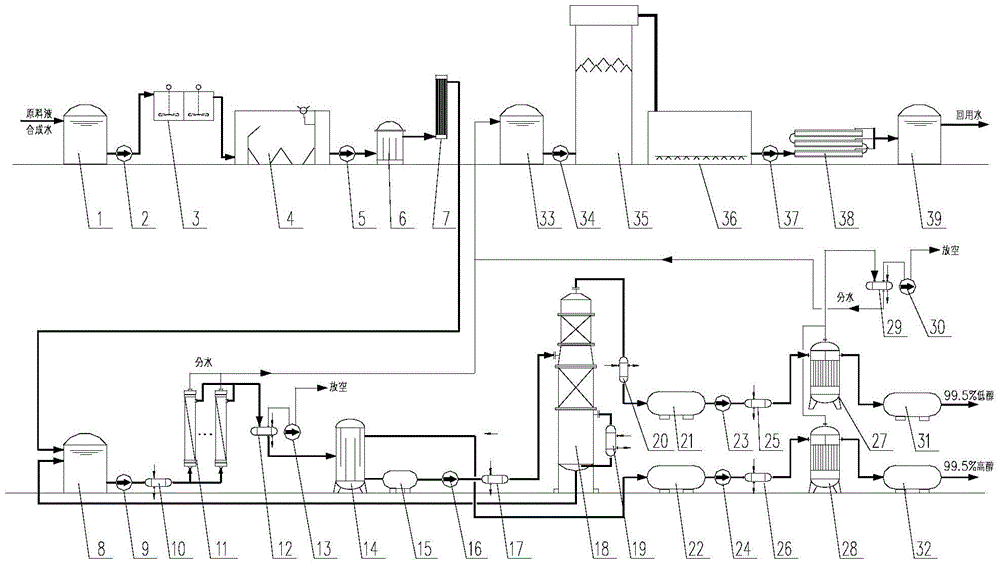

[0025] Such as figure 1 As shown, a Fischer-Tropsch synthetic water alcohol-water separation and recovery device is characterized in that it includes a pretreatment system, a separation system, a concentration system, a dehydration system and a water reuse system; wherein,

[0026] Pretreatment system: including sequentially connected raw material tank 1, first feed pump 2, neutralization reaction equipment 3, coagulation air flotation equipment 4, second feed pump 5, precision filter 6, membrane filter 7 and the first An intermediate feed liquid tank 8;

[0027] Separation system: including a third feed pump 9, a first heat exchanger 10, an alcohol permeable membrane device 11, a second heat exchanger 12, a first vacuum pump 13, a liquid-liquid separator 14, a second intermediate feed liquid tank 15, The fourth feed pump 16, the third heat exchanger 17, the feed port of the third feed pump 9 is connected to the first intermediate feed liquid tank 8, and the discharge port is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com