High-concentration breeding wastewater treatment process

A technology for aquaculture wastewater and treatment process, applied in the field of environmental protection, can solve problems such as poor treatment effect, inability to reuse or discharge, and achieve the effect of improving recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

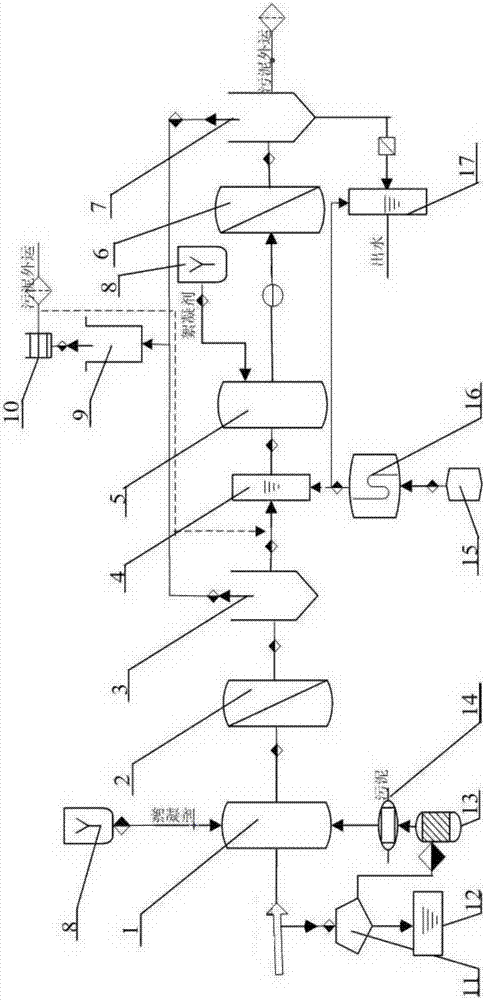

[0027] A high-concentration aquaculture wastewater treatment process, comprising the following steps: feeding the aquaculture wastewater into the fast stirring tank A1, the slow stirring tank A2, the suspension clarification tank A3, and the regulating tank A4, adding flocculant 100~ 150mg / L, stirring for 1-5min, 150rpm, the flocculant is compounded by KOE composite water purifying agent and calcium hydroxide, stirring for 5-30min in the slow stirring tank A(2), 350rpm, the floc and The upper layer of clear water, the upper layer of clear water obtained enters the adjustment tank A4, and the PH value is adjusted to 5-8 through the PH automatic adjustment device 16, and the flocs are separated by the suspension clarification tank A3 and separated by the sludge concentration tank 9, and the separated suspension enters the plate frame The filter press 10 forms solid sludge and suspension, and the suspension enters the adjustment tank A4, and the suspension A is obtained after adju...

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is that on the basis of embodiment 1, the purification treatment is carried out again, and the suspension A is sequentially passed into the fast stirring tank B5, the slow stirring tank B6, the suspension clarification tank B7, the regulating tank B17, Add KOE composite water purifying agent and calcium hydroxide to the fast stirring tank B5 to form flocculant 50-100mg / L, stir for 6-8min, 150rpm, slow stirring tank B6 stir 300rpm, and separate the flocs in the suspension clarification tank B7 With the upper clear water, the upper clear water is obtained and enters the adjustment tank B17, and the pH value is adjusted to 6-7 through the PH automatic adjustment device 16, and the flocs are separated by the suspension clarification tank B7 and separated by the sludge thickening tank 9, and the suspension obtained by the separation enters the plate Frame filter press 10 forms solid sludge and suspension, and the suspens...

Embodiment 3

[0033]The difference between this embodiment and the above-mentioned embodiments is that the aquaculture wastewater is pretreated before being passed into the stirring tank A. The specific pretreatment method is: the aquaculture wastewater is passed through the lime reaction tank (11) to degrade the macromolecular organic matter into small Molecular substances and sediments from the lime reaction tank enter the flocculant reaction tank (13) for coagulation reaction, and enter the sludge settling tank 14 after fully coagulating, and the supernatant of the sludge settling tank 14 enters the rapid stirring tank A1 for purification treatment, and the sludge The solids at the bottom of the mud sedimentation tank 14 are concentrated and discharged.

[0034] In this embodiment, the above-mentioned treatment is mainly aimed at organic pollutants that are difficult to degrade. The lime facultative bacteria in the lime reaction tank degrade the organic pollutants into small molecular org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com