Water-soluble polymer solution degrading agent, and preparation method and application thereof

A technology of water-soluble polymer and degrading agent, which is applied in the directions of drilling composition, water treatment parameter control, chemical instruments and methods, etc., can solve the problem of increased water treatment cost, increased treatment difficulty of polymers, and difficulty of produced water treatment. and other problems, to achieve good stability, improve the effect of recycling and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment provides a water-soluble polymer solution degradation agent, which is composed of the following substances in mass percentage: 1-5% of ferrous compound, 1-10% of ascorbic acid, and the rest is water.

[0020] Principle of the present invention:

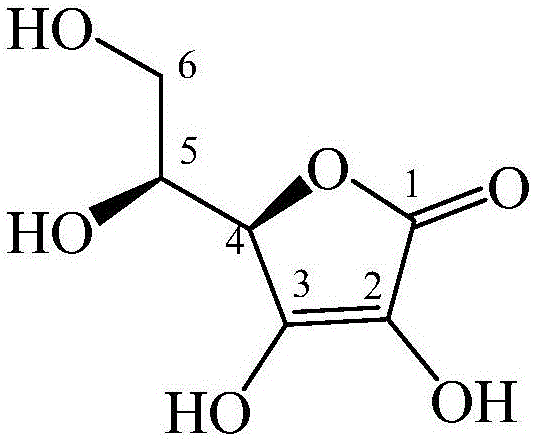

[0021] The molecular structure of ascorbic acid is as follows:

[0022]

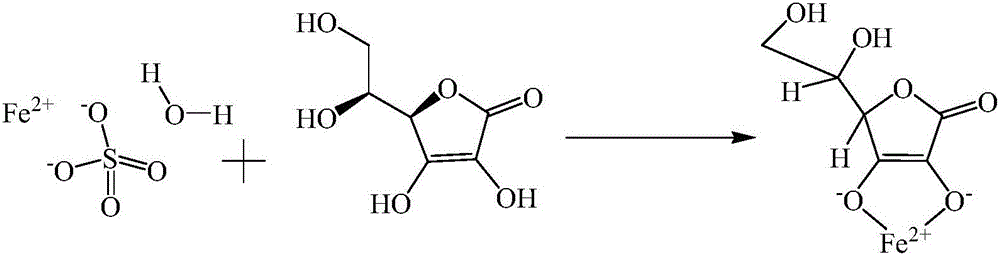

[0023] During the coordination process between ascorbic acid molecules and metal ions, the 2nd and 3rd atoms in the molecular structure contribute the most to the paramagnetism of metal ions (0.52, 1.6, 1.6, 0.42, 0.21, 0.09 in sequence), so the ascorbic acid solution and sub After the iron ion solution is mixed, the following reactions occur:

[0024]

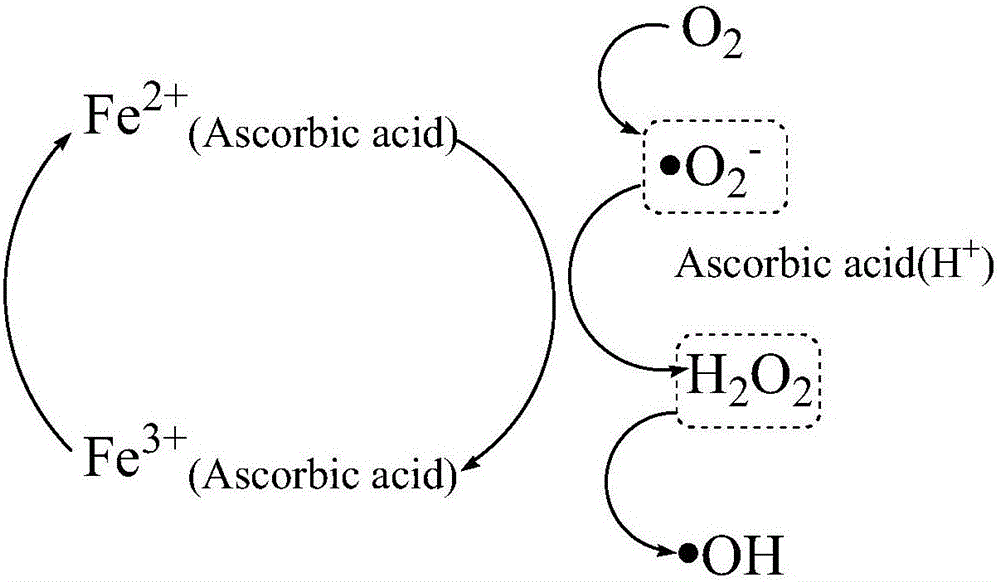

[0025] The mechanism of degradation agent is:

[0026]

[0027] Ascorbic acid itself is a green, low-cost, environment-friendly antioxidant, and ascorbic acid can interact with Fe 3+ Carry out a coordination reaction to generate soluble ferric iron, which is beneficial to the r...

Embodiment 2

[0029] On the basis of Example 1, this example provides a method for preparing a water-soluble polymer solution degradation agent, the steps are as follows:

[0030] (1) 5%wt ferrous compound aqueous solution and the 12%wt ascorbic acid solution of 1000g of preparing 1000g respectively;

[0031] (2) Add the ascorbic acid solution into the aqueous ferrous compound solution, and stir evenly to obtain the degradation agent.

Embodiment 3

[0033] This embodiment provides a kind of preparation method of water-soluble polymer solution degradation agent, and the steps are as follows:

[0034] (1) 10%wt ferrous compound aqueous solution and the 20%wt ascorbic acid solution of 1000g of preparing 1000g respectively;

[0035] (2) Add the ascorbic acid solution into the aqueous ferrous compound solution, and stir evenly to obtain the degradation agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com