Green direct drinking machine capable of recovering whole sensible heat

A water dispenser and green technology, which can be used in beverage preparation devices, heating devices, household appliances, etc., can solve the problems of secondary pollution of drinking water, easy scalding of children and the elderly, and potential safety hazards, so as to improve drinking water safety and save drinking water. Preparation time, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

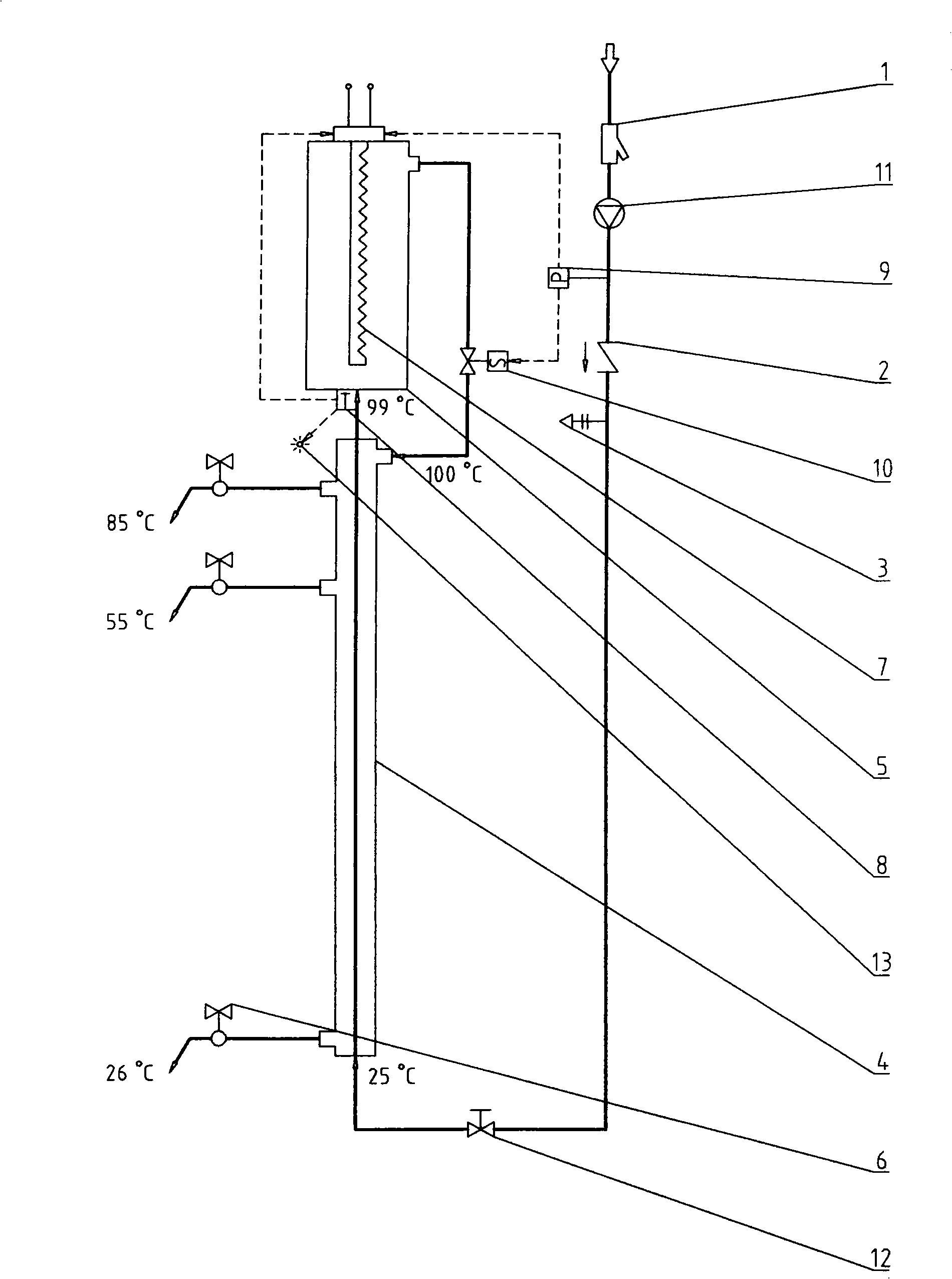

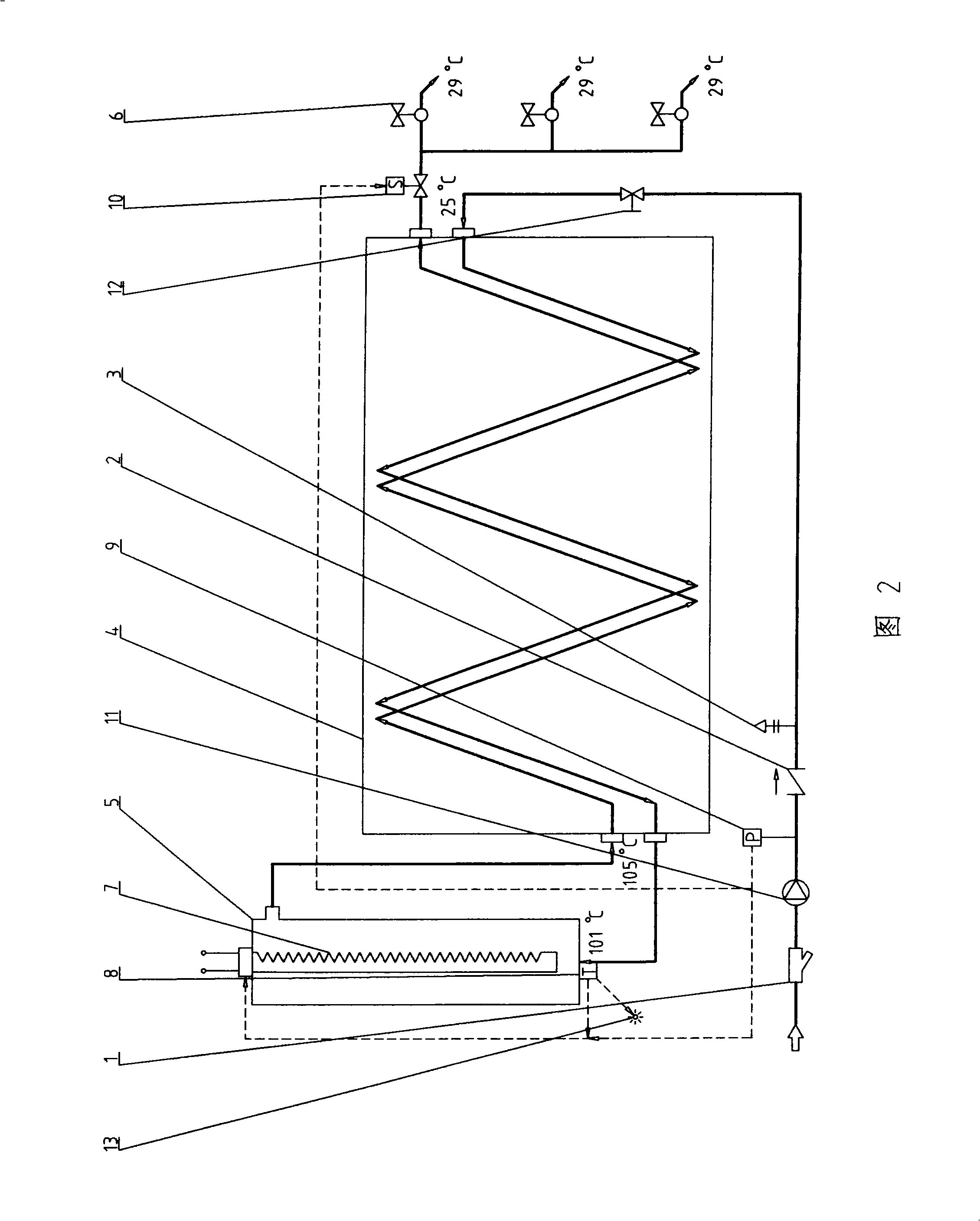

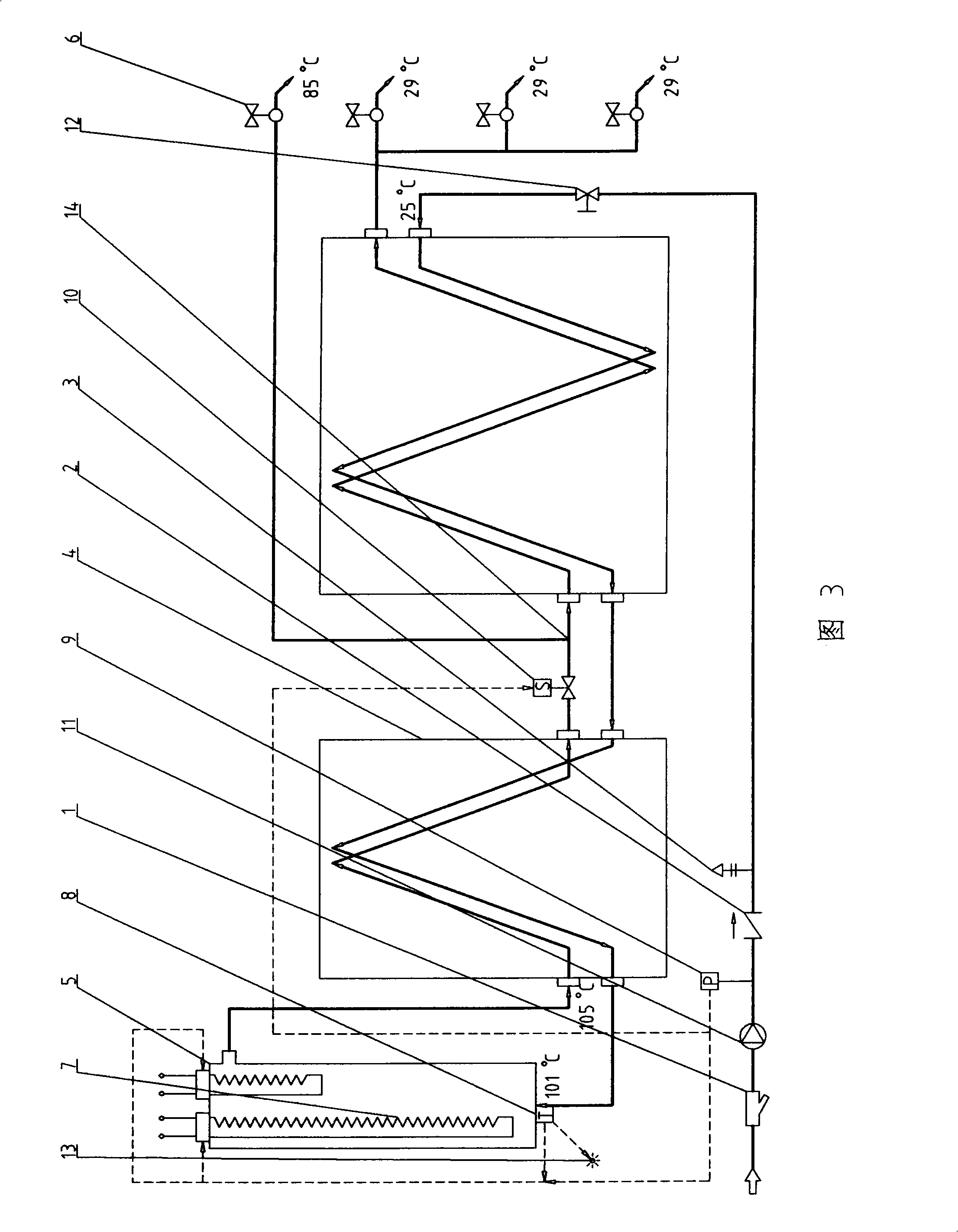

[0053] Embodiment 1 of reclaiming all sensible heat green direct water dispensers proposed by the present invention is shown in Figure 2, and is now described as follows: it consists of DN15 inner wire stainless steel filter 1, DN15 inner wire stainless steel check valve 2, DN15 inner wire stainless steel Pressure relief valve 3, DN15 internal wire stainless steel flow regulating stop valve 12, heat exchange area 1.827m 2 316 stainless steel plate type with thermal insulation regenerator 4 on the water side, 316 stainless steel heating / insulation pipe with a diameter of 70mm and a height of 400mm 5, with a thermal insulation regenerator 4 drinking water side, DN15 inner wire stainless steel solenoid valve 10, DN15 inner wire stainless steel drinking water The ball valve 6 and its 15mm diameter stainless steel connecting pipeline and pipe fittings constitute the heat recovery and heating branch; the heating / insulation pipe 5 and the 140W electric heating coil heating source 7 wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com