Coffee grounds shoe material and preparation method thereof

A technology for coffee grounds and shoe materials, applied in the field of shoe materials, can solve the problems of low practical value, pollute the environment, discarding, etc., and achieve the effects of slowing down the photooxidation process, beautiful color and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

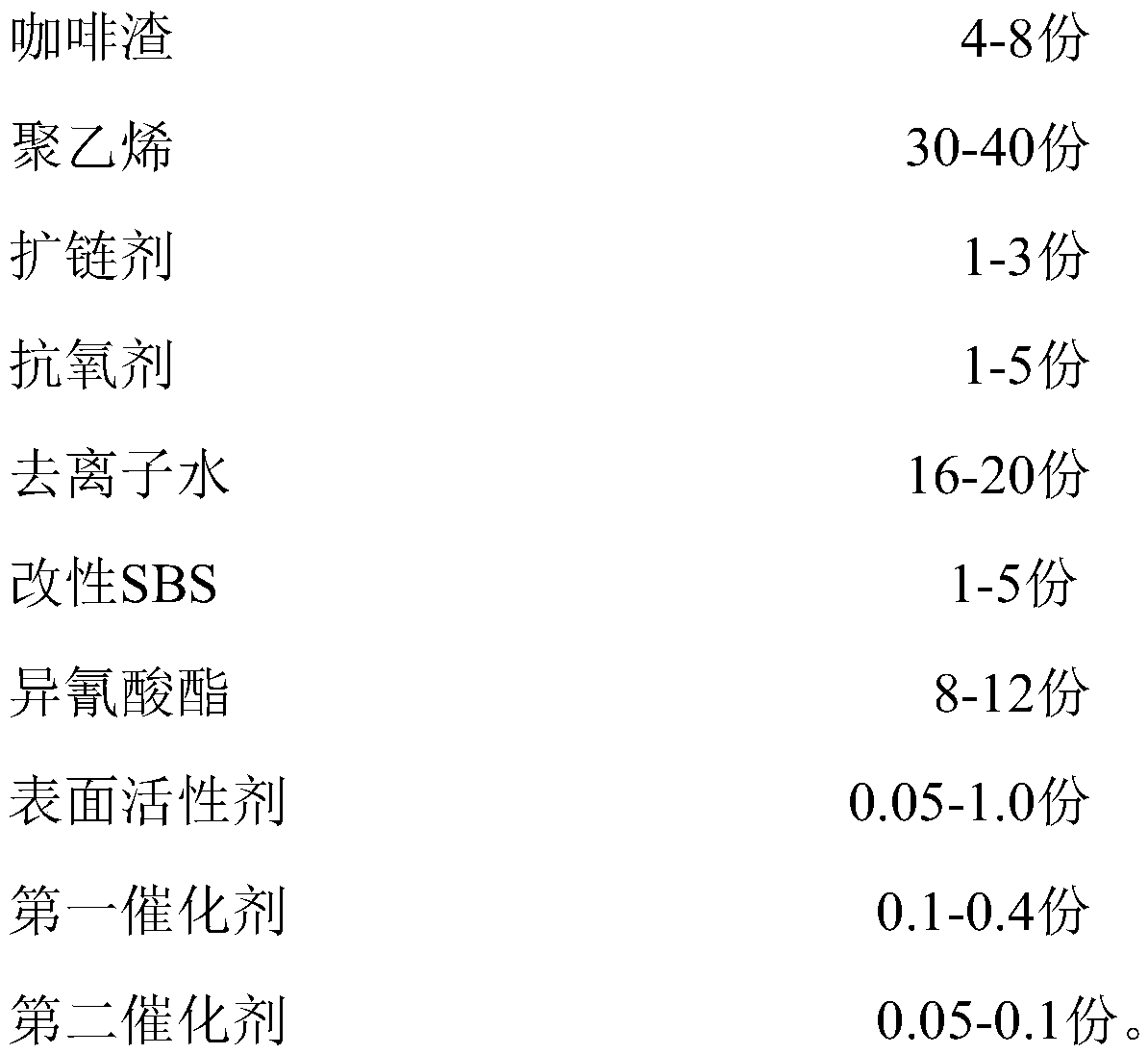

[0033] A coffee grounds shoe material, comprising the following raw materials in parts by weight:

[0034]

[0035] The isocyanate is preferably diphenylmethane diisocyanate.

[0036] Each part of the modified SBS includes the following raw materials in parts by weight:

[0037]

[0038] The modified SBS is prepared by the following method:

[0039] S1. According to parts by weight, add tin tetrachloride and calcium carbonate into the reaction device, heat to 70°C, and stir at a speed of 300r / min for 10min, obtain mixture A after cooling, and set aside;

[0040] S2. According to weight parts, add SBS and carbon black to the mixture A obtained in step S1, heat to 40°C, continue to stir for 8min, then heat the mixed system to 160°C and send it to a granulator for extrusion and granulation to obtain the improved sex SBS.

[0041] Each part of the surfactant is a mixture of sodium dodecylbenzenesulfonate, fatty acid glyceride and sodium hydroxysulfonate in a weight ratio ...

Embodiment 2

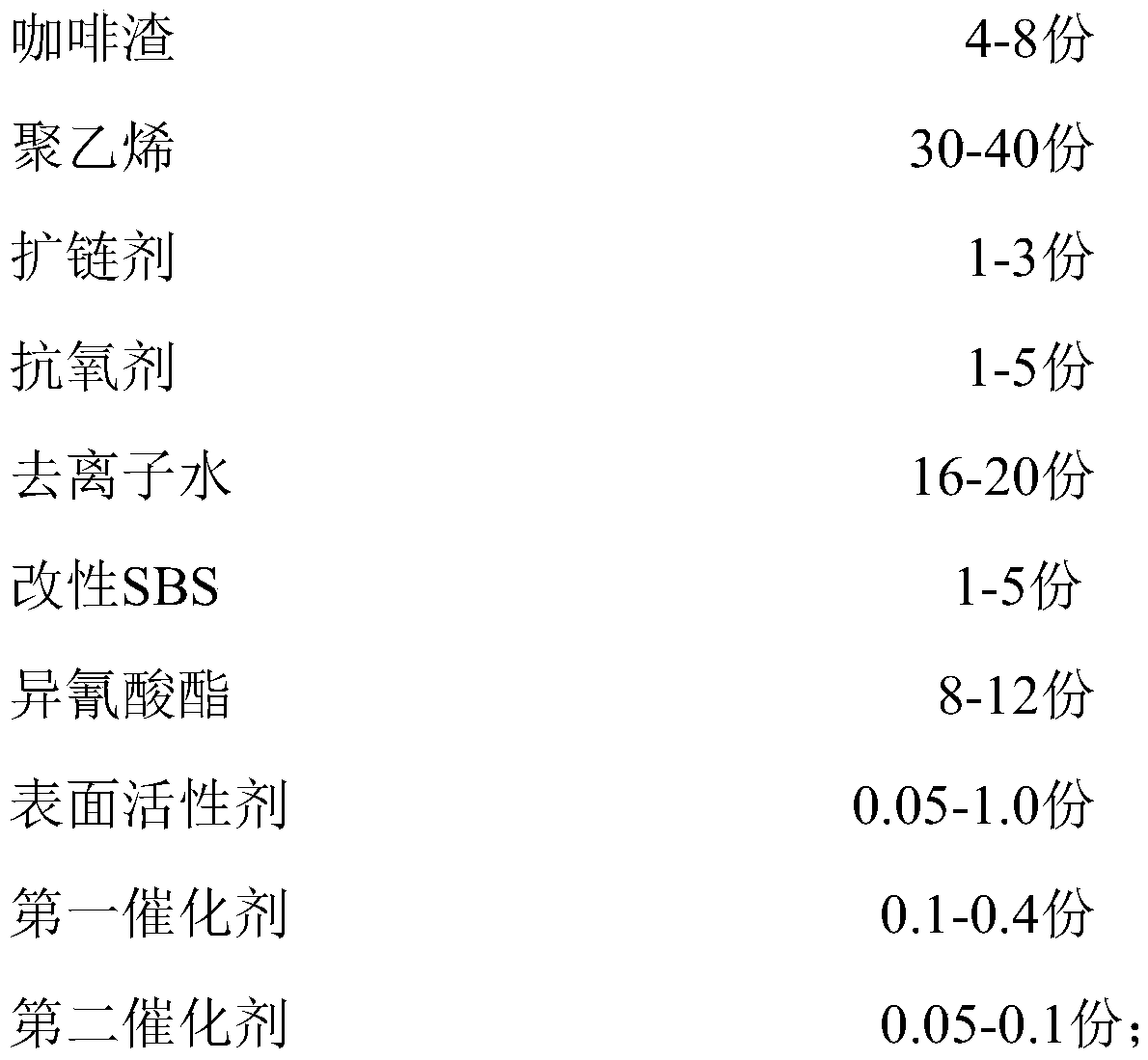

[0053] A coffee grounds shoe material, comprising the following raw materials in parts by weight:

[0054]

[0055] The isocyanate is preferably diphenylmethane diisocyanate.

[0056] Each part of the modified SBS includes the following raw materials in parts by weight:

[0057]

[0058] The modified SBS is prepared by the following method:

[0059] S1. According to parts by weight, add tin tetrachloride and calcium carbonate into the reaction device, heat to 76 ° C, and stir at a speed of 360 r / min for 13 min, and obtain mixture A after cooling, and set aside;

[0060] S2. According to weight parts, add SBS and carbon black to the mixture A obtained in step S1, heat to 45°C, continue to stir for 10min, then heat the mixed system to 170°C and send it to a granulator for extrusion and granulation to obtain improved sex SBS.

[0061] Each part of the surfactant is a mixture of sodium dodecylbenzenesulfonate, fatty acid glyceride and sodium hydroxysulfonate in a weight r...

Embodiment 3

[0073] A coffee grounds shoe material, comprising the following raw materials in parts by weight:

[0074]

[0075] The isocyanate is preferably diphenylmethane diisocyanate.

[0076] Each part of the modified SBS includes the following raw materials in parts by weight:

[0077]

[0078]

[0079] The modified SBS is prepared by the following method:

[0080] S1. According to parts by weight, add tin tetrachloride and calcium carbonate into the reaction device, heat to 85°C, and stir at a speed of 450r / min for 15min, and obtain mixture A after cooling, and set aside;

[0081] S2. According to weight parts, add SBS and carbon black to the mixture A obtained in step S1, heat to 50°C, continue to stir for 12min, then heat the mixed system to 180°C and send it to a granulator for extrusion and granulation to obtain improved sex SBS.

[0082] Each part of the surfactant is a mixture of sodium dodecylbenzenesulfonate, fatty acid glyceride and sodium hydroxysulfonate in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com