Preparation method of titanium dioxide/polysiloxane photocatalytic composite film

A technology of titanium dioxide and polysiloxane, which is applied in the field of preparing titanium dioxide/polysiloxane photocatalytic composite film, which can solve the problems of poor photocatalysis and ultraviolet shielding ability, poor mechanical properties of the coating, and no three-dimensional crosslinking structure. , to achieve excellent organic/inorganic amphotericity, obvious UV shielding effect, and excellent photocatalytic function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

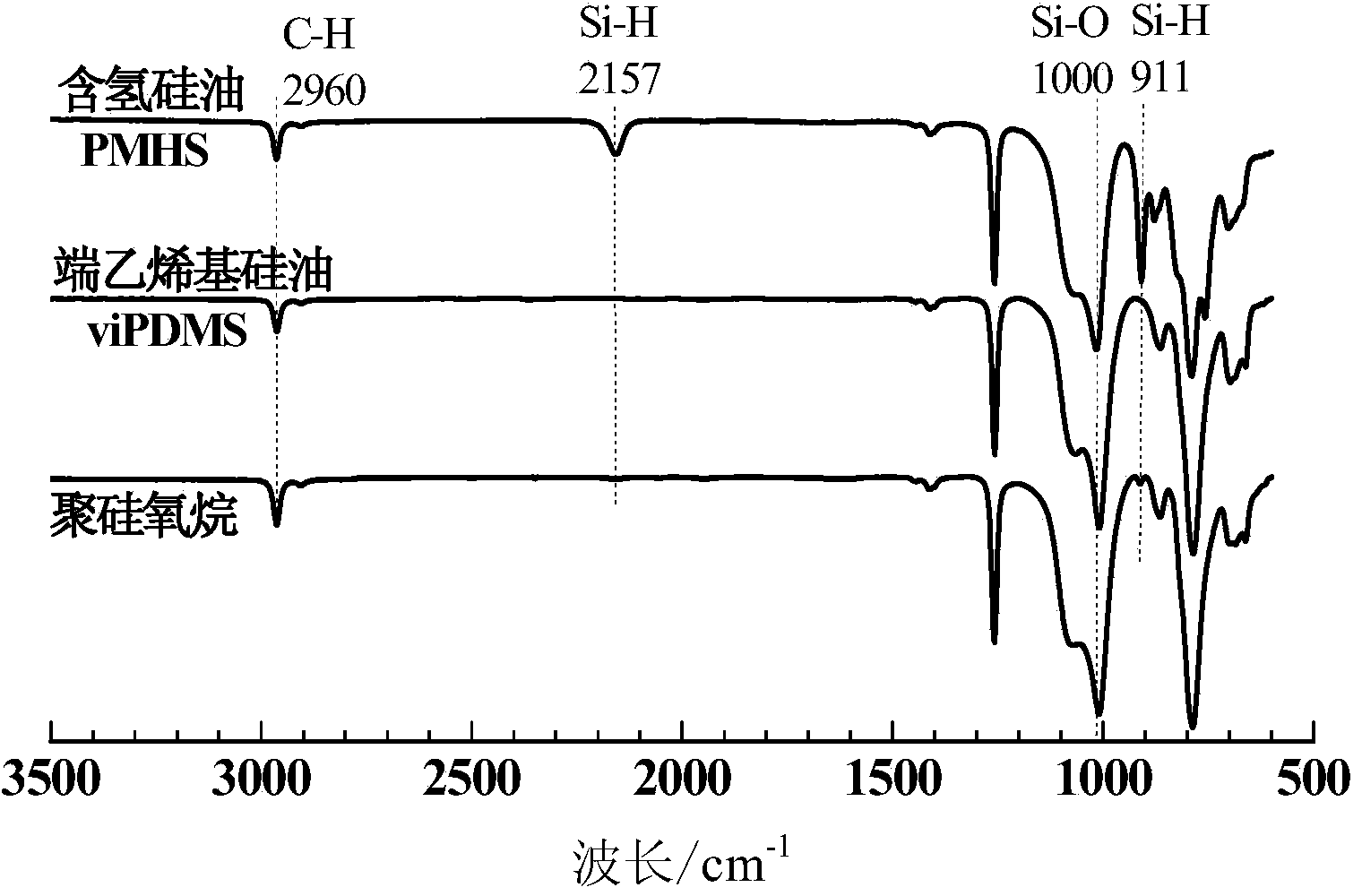

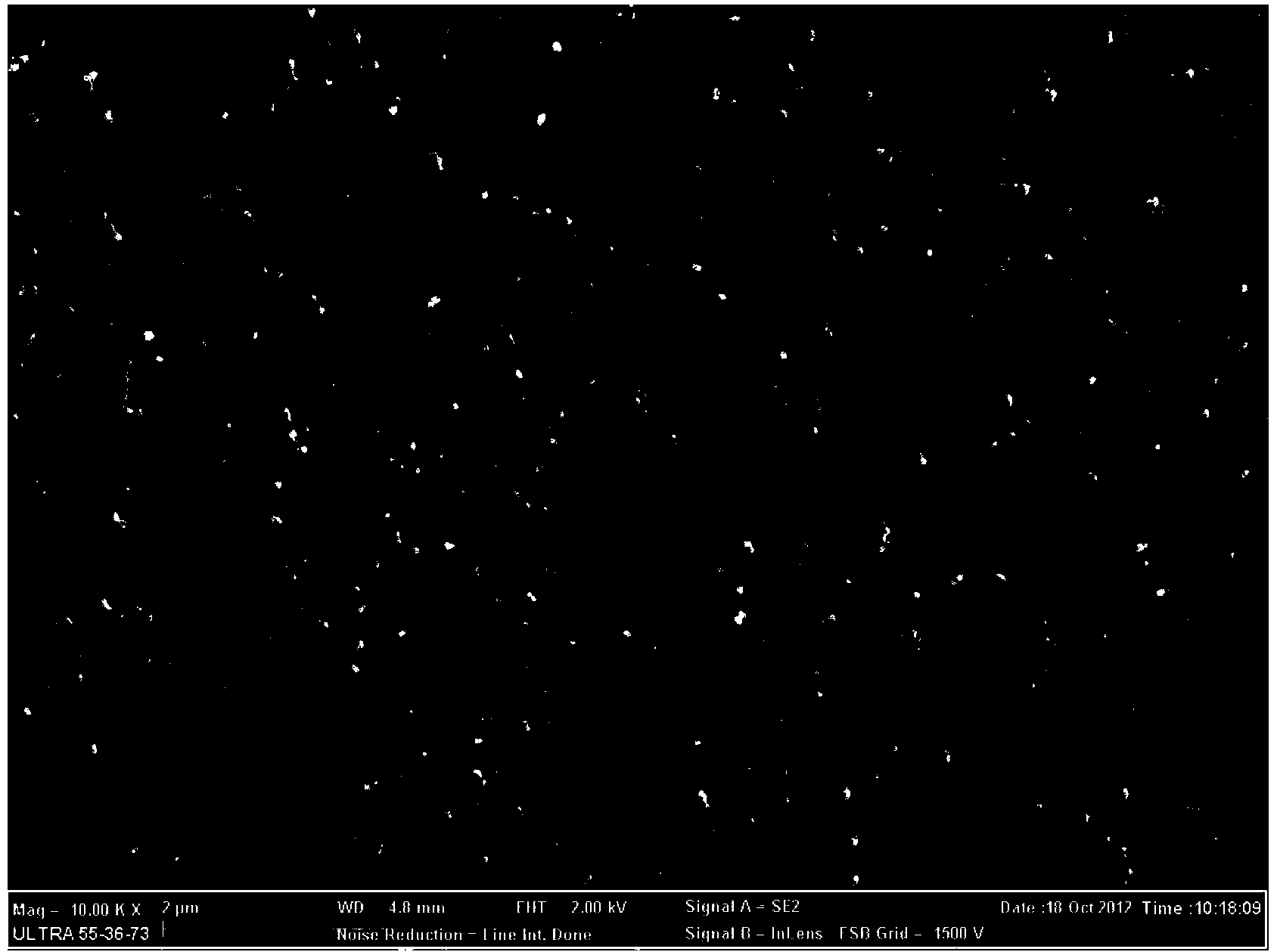

[0047] Under stirring, a certain amount of vinyl-terminated silicone oil viPDMS, hydrogen-containing silicone oil PMHS, titanium sol and reinforcing agent silicon dioxide (SiO 2 , powder) into the film-forming solvent, the film-forming solvent and the dispersion medium in the titanium sol are selected from toluene, and mixed uniformly (the total weight of vinyl silicone oil viPDMS and hydrogen-containing silicone oil PMHS is 100g, which is used as a benchmark for the quality of other materials) . The Karstedt platinum catalyst was added dropwise to initiate the hydrosilylation reaction between silicone oils, and poured into a polytetrafluoroethylene mold. At a dry room temperature of 25°C, a film is gradually formed with the volatilization of the solvent and the progress of the hydrosilylation reaction, and a three-dimensional cross-linked structure is built. After 24 hours, a titanium sol particle uniformly dispersed in the polysiloxane matrix is obtained. oxygen

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com