Preparation of cerium dioxide photocatalyst with exposed high-energy crystal face

A technology of cerium oxide and photocatalyst, which is applied in the direction of cerium oxide/cerium hydroxide, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the problem of low photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, cubic CeO 2 preparation of

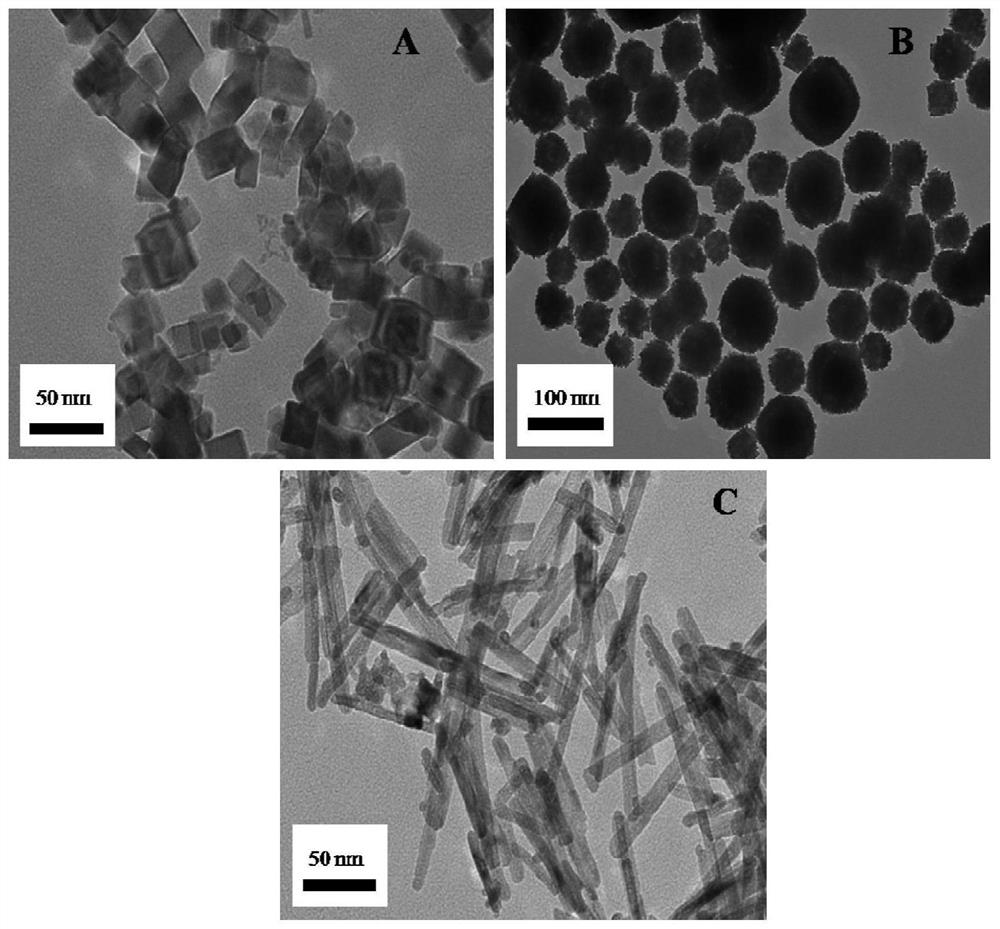

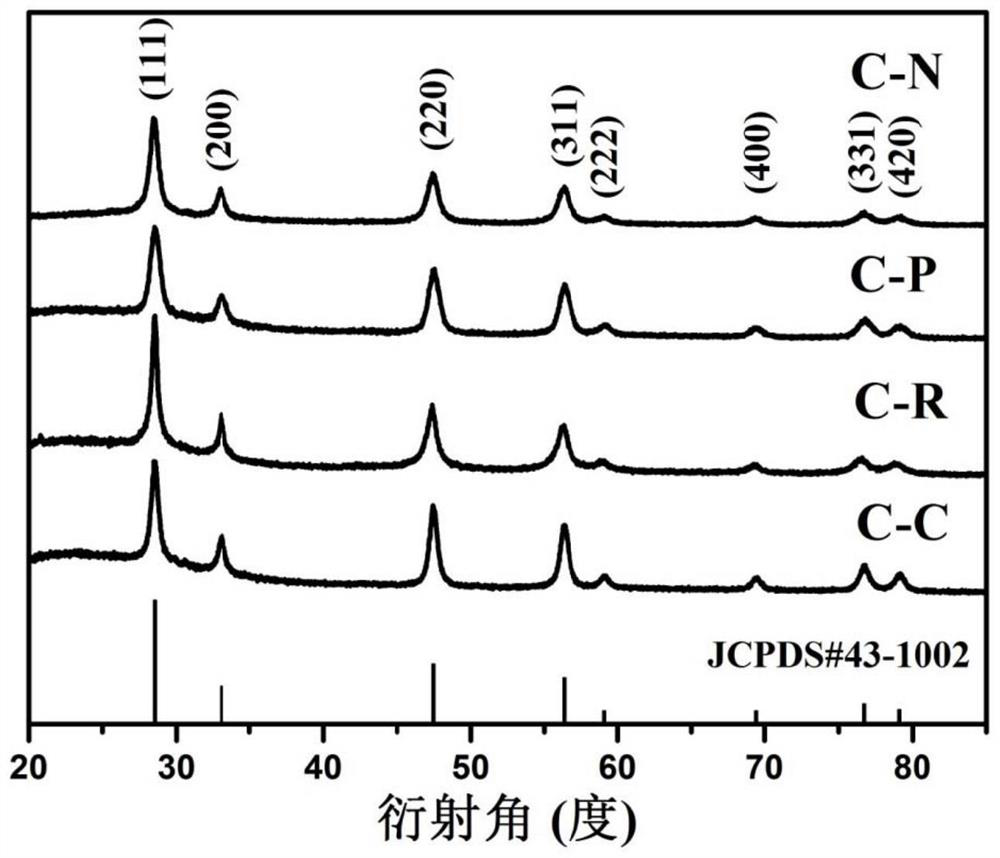

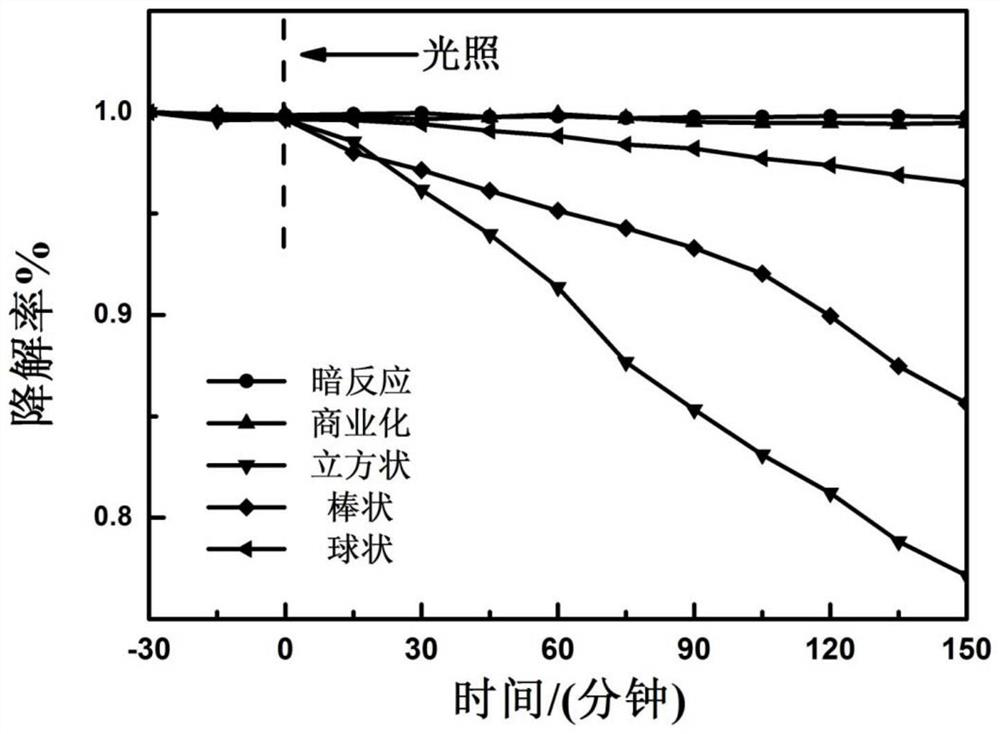

[0018] 10mmol Ce(NO 3 ) 3 ·6H 2 O was dissolved in 25ml deionized water, stirred for 10min, and recorded as solution A. At the same time, measure 50ml of 9mol / L NaOH solution, stir for 0.5h, and record it as solution B. Then the B solution was added dropwise to the A solution. Stir at room temperature for 0.5 h, transfer the above suspension into a 150 ml polytetrafluoroethylene reactor, and heat at 180° C. for 12 h. Then the mixture was cooled to room temperature, suction filtered to obtain solid particles, washed three times with deionized water and absolute ethanol, dried at 80°C for 6 hours, and cube-shaped CeO was obtained after grinding. 2 , whose structure is as figure 1 a.

Embodiment 2

[0019] Embodiment 2, nano spherical CeO 2 preparation of

[0020] 10mmol Ce(NO 3 ) 3 ·6H 2 O was dissolved in 25ml deionized water, stirred for 0.5h, and recorded as solution A. At the same time, measure 50ml of 0.2mol / L NaOH solution, stir for 0.5h, and record it as B solution. Then the B solution was added dropwise to the A solution. After stirring at room temperature for 0.5 h, the above suspension was transferred to a 150 ml polytetrafluoroethylene reactor and heated at 100° C. for 12 h. Then the mixture was cooled to room temperature, filtered with suction to obtain solid particles, washed three times with deionized water and absolute ethanol, dried at 80°C for 6 hours, and ground to obtain CeO 2 nanospheres, whose structure is as figure 1 b.

Embodiment 3

[0021] Embodiment 3, Rod CeO 2 preparation of

[0022] 10mmol Ce(NO 3 ) 3 ·6H 2 O was dissolved in 25ml deionized water, stirred for 0.5h, and recorded as solution A. At the same time, measure 50ml of 6mol / L NaOH solution, stir for 0.5h, and record it as B solution. Then the B solution was added dropwise to the A solution. After stirring at room temperature for 0.5 h, the above suspension was transferred to a 150 ml polytetrafluoroethylene reactor and heated at 110° C. for 12 h. Then the mixture was cooled to room temperature, filtered with suction to obtain solid particles, washed three times with deionized water and absolute ethanol, dried at 80°C for 6 hours, and ground to obtain rod-shaped CeO 2 , whose structure is as figure 1 c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com