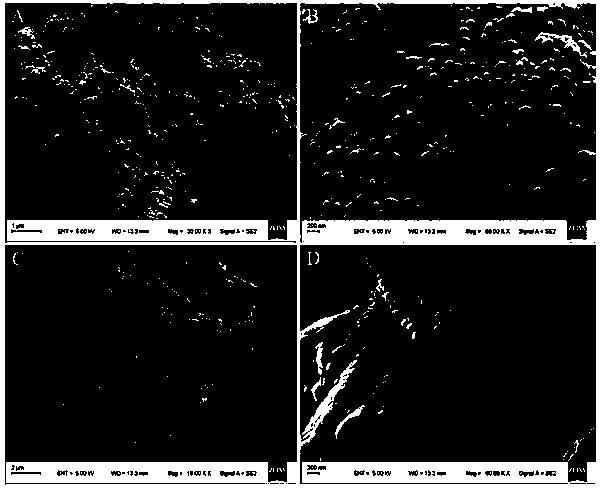

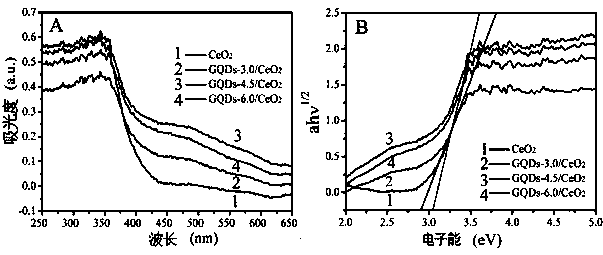

Preparation method of rodlike structure graphene quantum dot/cerium oxide composite photocatalyst

A graphene quantum dot and rod-like structure technology, applied in the field of photocatalytic applications and composite materials, can solve problems such as unsatisfactory catalytic performance, and achieve the effect of improving photocatalytic ability and enhancing transfer life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

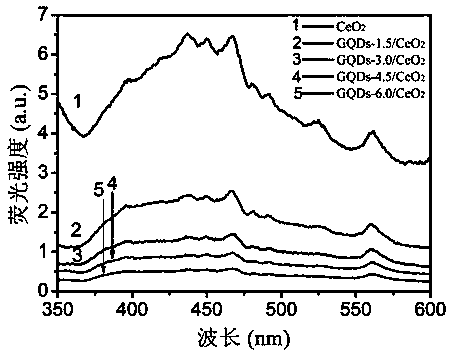

[0026] GQDs / CeO 2 Composite material: weigh 0.1 g CeO 2 Nanoparticles and 1.5 mg GQDs (1.5 wt%) were dispersed in 20 mL of aqueous solution, ultrasonically dispersed for 30 min; then transferred to a reaction kettle, heated to 100 °C for 3 h; cooled, and the product was centrifuged (9000-10000 rpm) , washed with ultrapure water, and vacuum freeze-dried at -50°C for 10 h to obtain GQDs-1.5 / CeO 2 composite material.

[0027] GQDs-1.5 / CeO 2 The removal rate of the composite material for RhB: 79.3% in 180 min.

Embodiment 2

[0029] GQDs / CeO 2 Composite material: weigh 0.1 g CeO 2 Nanoparticles and 3.0 mg GQDs (3.0 wt%) were dispersed in 20 mL of aqueous solution, ultrasonically dispersed for 30 min; then transferred to a reaction kettle, heated to 100 °C for 3 h; cooled, and the product was centrifuged (9000-10000 rpm) , washed with ultrapure water, and vacuum freeze-dried at -50°C for 10 h to obtain GQDs-3.0 / CeO 2 composite material.

[0030] GQDs-3.0 / CeO 2 The removal rate of the composite material for RhB: 93.3% in 180 min.

Embodiment 3

[0032] GQDs / CeO 2 Composite material: weigh 0.1 g CeO 2 Nanoparticles and 4.5mg GQDs (4.5 wt%) were dispersed in 20mL aqueous solution, ultrasonically dispersed for 30 min; then transferred to a reaction kettle, heated to 100°C for 3 h; cooled, and the product was centrifuged (9000-10000 rpm) , washed with ultrapure water, and vacuum freeze-dried at -50°C for 10 h to obtain GQDs-4.5 / CeO 2 composite material.

[0033] GQDs-4.5 / CeO 2 The removal rate of the composite material for RhB: 94.4% in 180 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com