Industrial preparation method of non-oxidative cerium oxide nanoparticles

A nano-particle, non-oxidizing technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of cost increase, production waste treatment volume, low catalytic activity, etc., and achieve easy dispersion, good dispersion, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

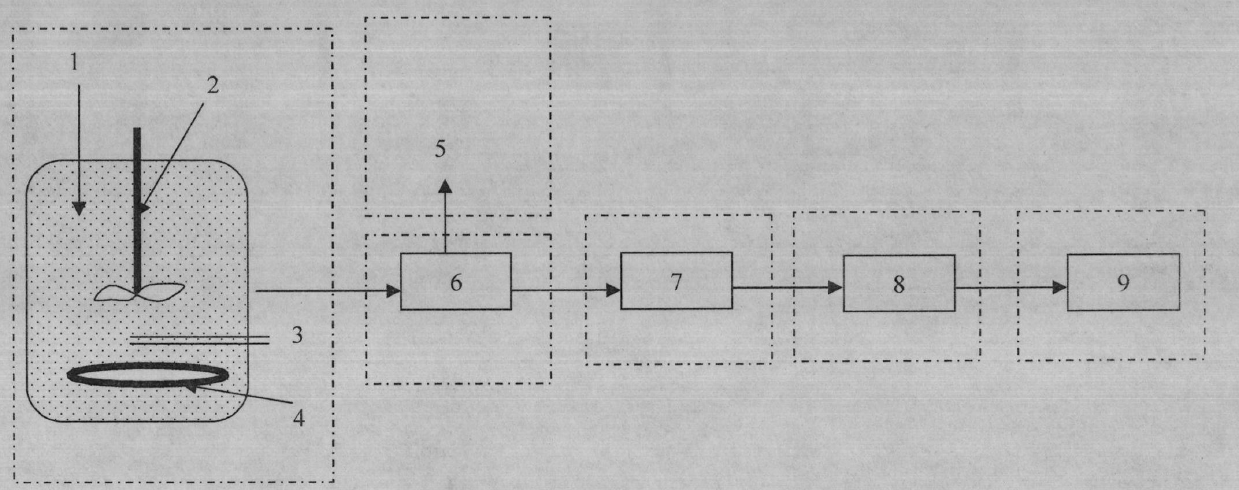

Method used

Image

Examples

Embodiment 1

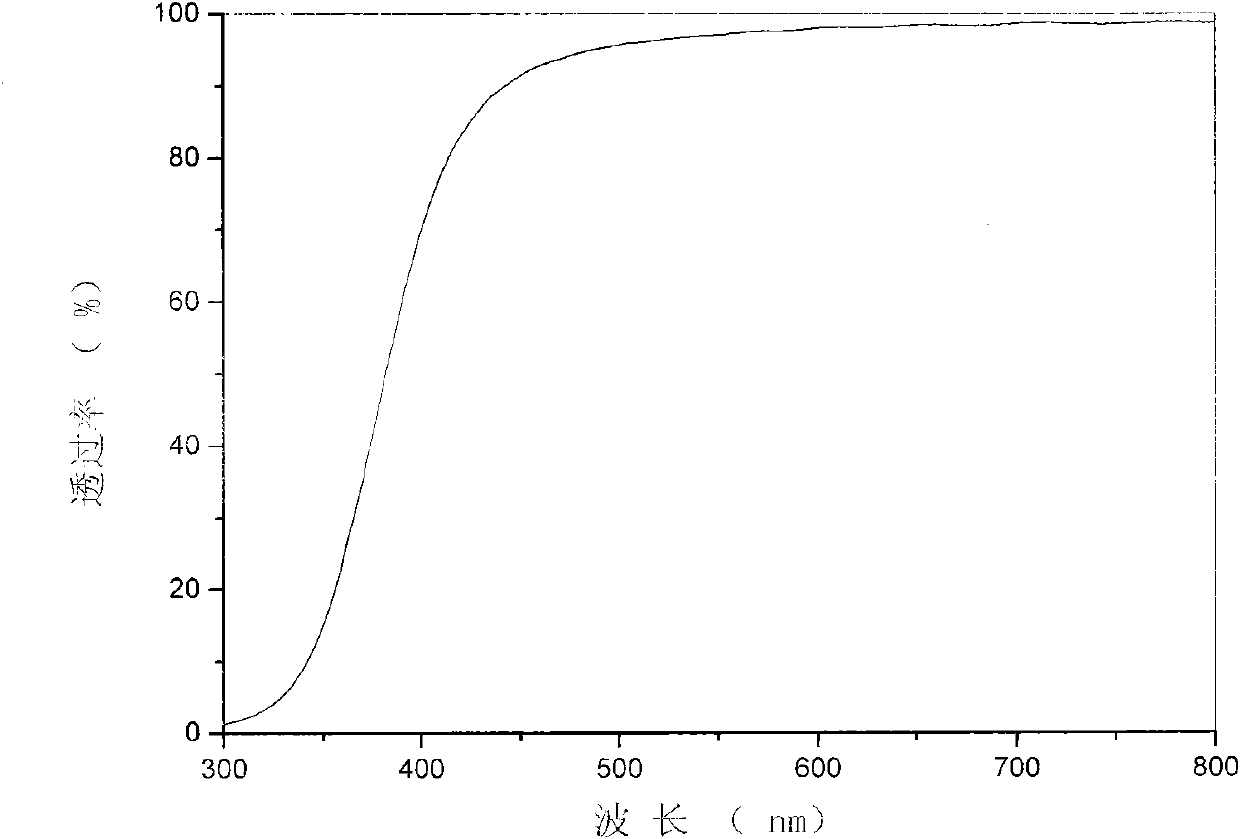

[0038] Example 1 Industrialized preparation of cerium oxide nanoparticles: the raw material is cerium chloride, using methanol as a solvent, configured into a transparent salt solution with a concentration of 0.5M, and then adding an organic gelling agent propylene oxide with a molar ratio of 5 to cerium ions , after mixing evenly, the solution was placed in a water bath at 50°C and stirred for 1 hour, and the obtained sol was dried at 80°C until a xerogel was obtained, and loose non-surface-modified CeO was obtained after light grinding. 2 Nanoparticles.

Embodiment 2

[0039] Example 2 Industrial preparation of cerium oxide nanoparticles: ethanol is used as solvent, and the others are the same as in Example 1.

Embodiment 3

[0040] Example 3 The industrialized preparation of non-oxidizing cerium oxide nanoparticles: the CeO obtained in Example 2 2 Nanoparticles and CeO 2 After the surface modifier sodium metasilicate of 50% by weight is ground and mixed evenly, add an additive with a molar ratio of 1 to sodium metasilicate and be CeO 2 1% by weight of the surfactant sodium dodecylbenzenesulfonate was ground and mixed for 0.5 hours for surface modification, the modified powder was washed several times with deionized water and dried at 100°C to dry powder, then 500°C Calcined for 1 hour to obtain non-oxidizing CeO 2 Nanoparticles.

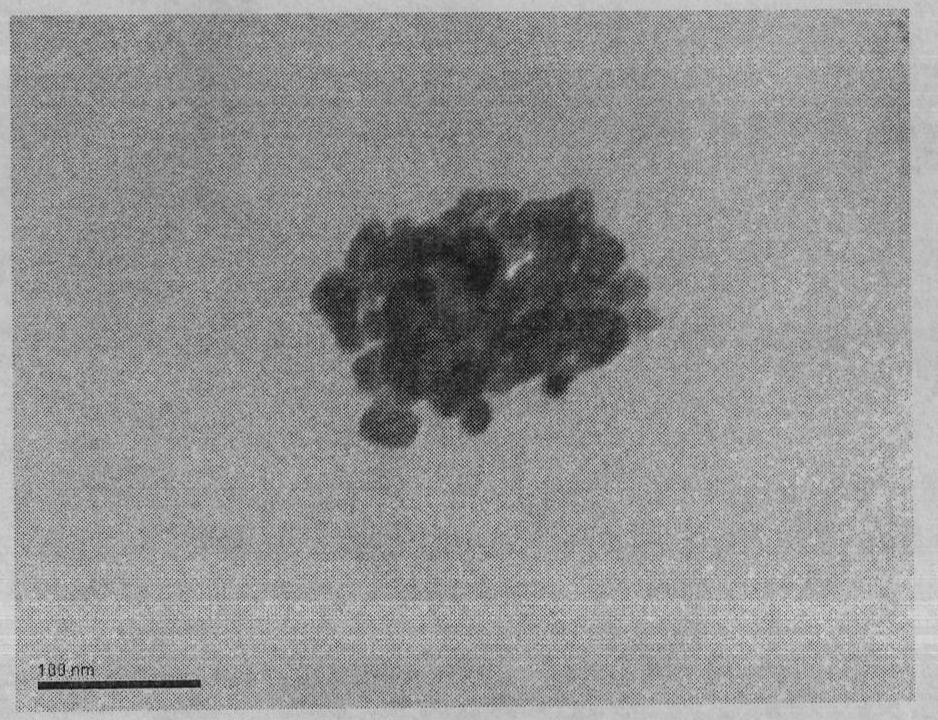

[0041] figure 2 For the obtained CeO 2 X-ray diffraction pattern of nanoparticles, surface modified CeO visible 2 The X-ray diffraction pattern of nanoparticles, it can be judged that the diffraction peaks in the spectrum are all CeO 2 The characteristic diffraction peaks, no impurity exists, and its particle size can be judged to be in the nanometer range from it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com