Preparation method of ZIF-67 carbide-loaded nano CeO2 oxygen reduction catalyst

A technology of ZIF-67 and catalyst, applied in the field of fuel cell electrocatalysis, can solve the problems of high cost, low efficiency and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

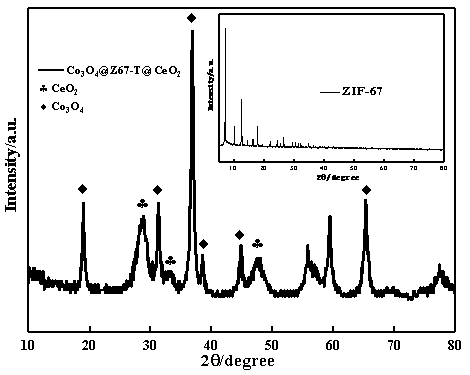

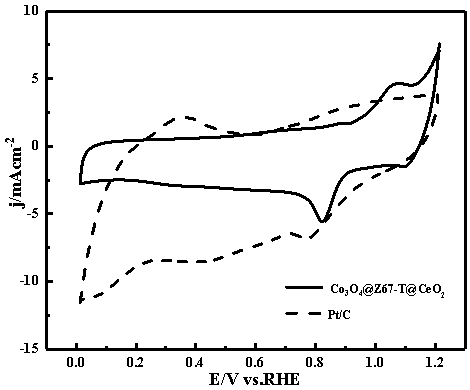

[0028] In this implementation method Co 3 o 4 @Z67-T @CeO 2 The preparation method of the nano electrocatalyst is as follows: 1. A certain amount of Co(NO 3 ) 2 ·6H 2O and 2-methylimidazole were respectively dissolved in 25mL of methanol, stirred, sonicated, left standing, centrifuged, washed, and dried to obtain the ZIF-67 polyhedral material (purple); 2. Place the dried ZIF-67 obtained in step 1 After high-temperature carbonization in a nitrogen atmosphere tube furnace and keeping at the highest temperature for 2 hours, Co 3 o 4 @Z67-T powdery substance (black); 3. Ultrasonically disperse the black powder in step 2 in 10mL ethylene glycol, pour an appropriate amount of Ce(NO 3 ) 3 ·6H 2 O aqueous solution, and stir rapidly to form a uniform mixed solution; 4. Pour the mixed solution in step 3 into a polytetrafluoroethylene high-pressure reactor, and after a hydrothermal reaction at 160°C for 16 hours, suction filter, wash, and dry to obtain the final Product Co 3 o...

Embodiment approach 2

[0029] Specific implementation method two: the difference between this implementation method and the specific implementation method one is: m(Co 3 o 4 @Z67-T): m(Ce(NO 3 ) 3 ·6H 2 O=1.0:0.4, others are the same as the specific implementation method 1.

Embodiment approach 3

[0030] Specific implementation method three: the difference between this implementation method and specific implementation method one is: m(Co 3 o 4 @Z67-T): m(Ce(NO 3 ) 3 ·6H 2 O=1.0:0.6, others are the same as the specific implementation method 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com