Co-based nano-catalyst for hydrogen production by ethanol steam reforming and preparation method thereof

A steam reforming, cobalt-based catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of difficult to obtain high specific surface area, high Dispersion and uniform dispersion of catalysts, it is difficult to solve the problems of catalytic deactivation, catalyst carbon deposition, etc., to achieve good catalytic activity, high catalytic activity and selectivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The molar ratio of nitrate (cobalt nitrate, zinc nitrate and cerium nitrate is 4:1:1), orthosilicate, ethylene glycol, and phosphoric acid is prepared in two steps in a molar ratio of 0.25:1:4:0.012 Contains metallic silicone gel. First, nitrate (cobalt nitrate, cerium nitrate and zinc nitrate) and ethylene glycol solvent are used as raw materials, and metal-containing ethylene glycol is synthesized after magnetic stirring and heating at 90 ° C for 9 h; Stir and heat at 90°C for 10 hours to form a metal-containing silica sol in situ; age at 60°C for 3 days, put it in an autoclave, and pre-fill with N 2 To 3.0Mpa, use isopropanol as the medium, heat up to 260°C at a heating rate of 60°C / h, keep the temperature constant for 1 hour, release the pressure slowly at a speed of 3MPa / h, and use N 2 Rinse the autoclave for 30 minutes, turn off the power supply, and allow it to cool down naturally to prepare a cobalt-based catalyst for hydrogen production by steam reforming of e...

Embodiment 2

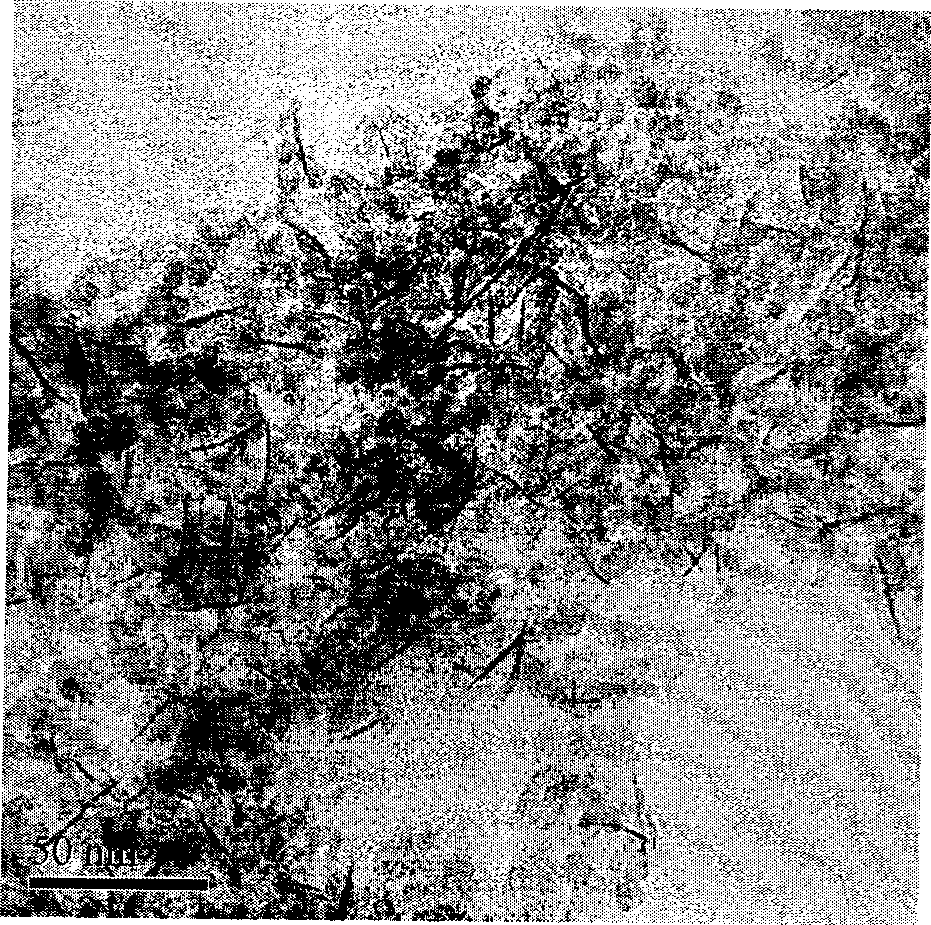

[0037] The molar ratio of nitrate (cobalt nitrate, zinc nitrate and cerium nitrate is 8:2:1), orthosilicate, ethylene glycol, and phosphoric acid is prepared in two steps in a molar ratio of 0.25:1:3:0.010. Contains metallic silicone gel. With mixed nitrate (cobalt nitrate, aluminum nitrate and cerium nitrate) and ethylene glycol solvent as raw materials, the metal-containing ethylene glycol was synthesized after magnetic stirring and heating at 90 ° C for 9 hours; then the metal-containing ethylene glycol and silicon alkoxide in Magnetic stirring and heating at 90°C for 10 hours form metal-containing silica sol in situ; aging at 60°C for 3 days, and perform supercritical drying treatment on the obtained metal-containing silicon wet gel according to Example 1 to obtain ethanol steam reforming Cobalt-based nanocatalyst for hydrogen production, the metal cobalt active component is in the form of one-dimensional nanowires, with a diameter of 1-5nm and a length of 10-50nm, ZnO and...

Embodiment 3

[0040] The molar ratio of nitrate (cobalt nitrate, zinc nitrate and cerium nitrate is 8:3:1), orthosilicate, ethylene glycol, and phosphoric acid is prepared in two steps in a molar ratio of 0.25:1:3:0.010. Contains metallic silicone gel. With mixed nitrate (cobalt nitrate, aluminum nitrate and cerium nitrate) and ethylene glycol solvent as raw materials, the metal-containing ethylene glycol was synthesized after magnetic stirring and heating at 90 ° C for 9 hours; then the metal-containing ethylene glycol and silicon alkoxide in Magnetic stirring and heating at 90°C for 10 hours form metal-containing silica sol in situ; aging at 60°C for 3 days, and perform supercritical drying treatment on the obtained metal-containing silicon wet gel according to Example 1 to obtain ethanol steam reforming Cobalt-based nanocatalyst for hydrogen production, the metal cobalt active component is in the form of one-dimensional nanowires, with a diameter of 1-5nm and a length of 10-50nm, ZnO and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com