CeO2 nano-particles for chemical mechanical polishing and preparation method of CeO2 nano-particles

A nanoparticle and chemical-mechanical technology, applied in nanotechnology for materials and surface science, preparation/processing of rare earth metal compounds, nanotechnology, etc., can solve the problem of rough particle shape, long processing time, complex preparation process, etc. problems, to achieve the effect of cheap raw materials, short production cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

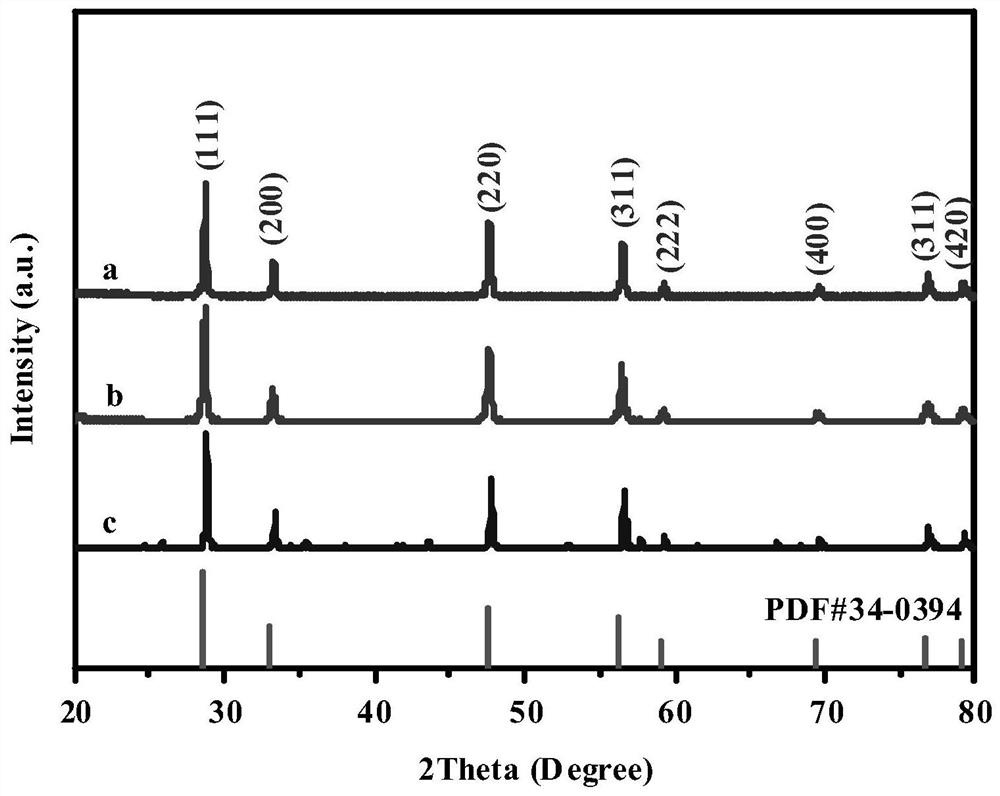

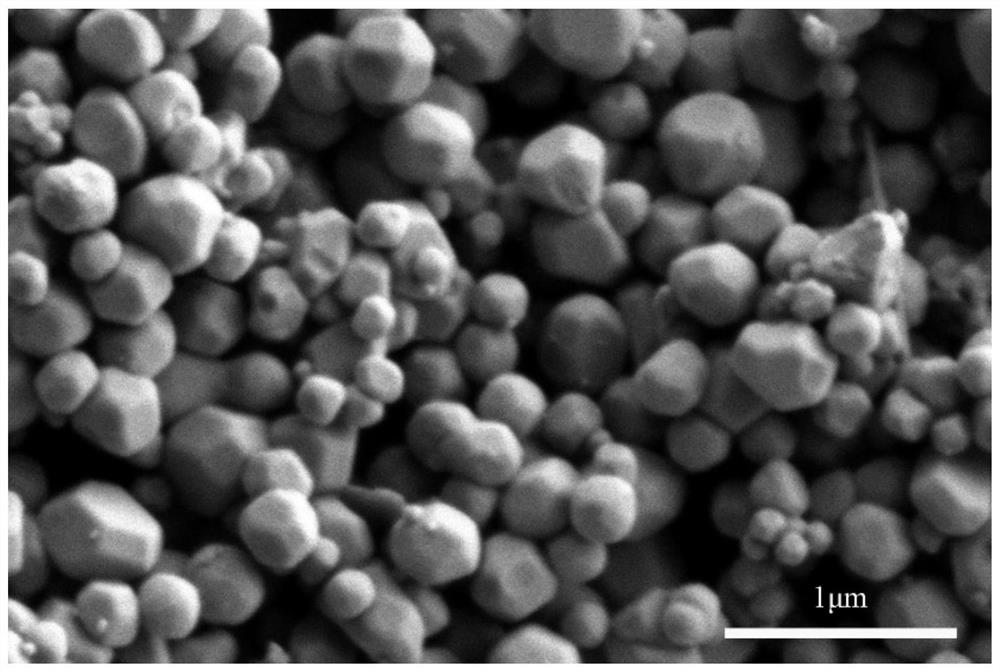

[0026] A kind of CeO used for chemical mechanical polishing of the present invention 2 The preparation method of nanoparticles comprises the following specific steps:

[0027] Step 1: Weigh 1.3026g (3mmol) of cerium nitrate hexahydrate, 1.2749g (15mmol) of sodium nitrate, and 0.8766g (15mmol) of sodium chloride respectively, grind and mix to obtain a mixture.

[0028] Step 2: Pour 3mmol of the mixture in step 1 into 15ml of absolute ethanol and mix, stir magnetically for 30min at a speed of 600r / min, pour it into a crucible, and dry it in a drying oven at 60°C for 4h to obtain Mix the salt.

[0029] Step 3: Put the mixed salt in step 2 together with the crucible in a muffle furnace, raise the temperature from room temperature to 800°C at a rate of 5°C / min and keep it warm for 3 hours, cool down to 500°C at a rate of 5°C / min and then cool naturally .

[0030] Step 4: Take out the reaction product in step 3, place the reaction product in a beaker on a magnetic stirrer, stir a...

Embodiment 2

[0034] A kind of CeO used for chemical mechanical polishing of the present invention 2 The preparation method of nanoparticles comprises the following specific steps:

[0035] Step 1: Weigh 1.3026g (3mmol) of cerium nitrate hexahydrate, 1.5156g (15mmol) of potassium nitrate, and 1.1183g (15mmol) of potassium chloride, respectively, grind and mix to obtain a mixture.

[0036] Step 2: Pour 3mmol of the mixture in step 1 into 18ml of absolute ethanol and mix, stir magnetically for 30min at a speed of 500r / min, pour it into a crucible, and dry it in a drying oven at 60°C for 4h to obtain Mix the salt.

[0037] Step 3: Put the mixed salt in step 2 together with the crucible in a muffle furnace, raise the temperature from room temperature to 700°C at a rate of 5°C / min and keep it for 3 hours, cool down to 500°C at a rate of 5°C / min and then cool naturally.

[0038] Step 4: Take out the reaction product in step 3, place the reaction product in a beaker on a magnetic stirrer, stir a...

Embodiment 3

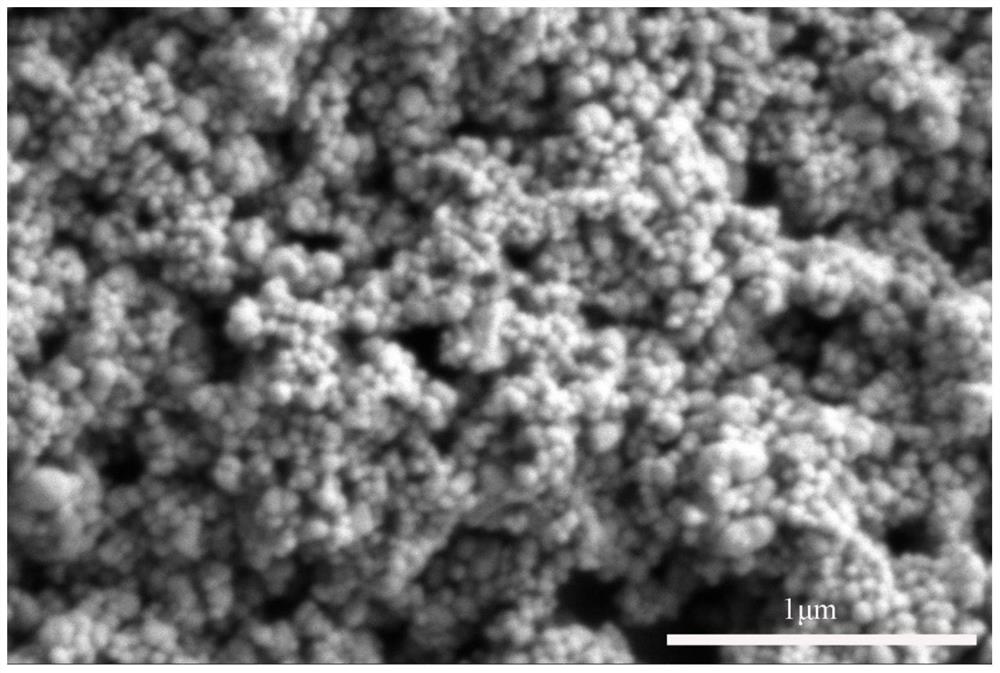

[0042] A kind of CeO used for chemical mechanical polishing of the present invention 2The preparation method of nanoparticles comprises the following specific steps:

[0043] Step 1: Weigh 1.3026g (3mmol) of cerium nitrate hexahydrate, 2.63g (45mmol) of sodium chloride, and 5.59g (75mmol) of potassium chloride, grind and mix to obtain a mixture.

[0044] Step 2: Pour 3mmol of the mixture in step 1 into 20ml of absolute ethanol and mix, stir magnetically for 30min at a speed of 500r / min, pour it into a crucible, and dry it in a drying oven at 70°C for 3h to obtain Mix the salt.

[0045] Step 3: Put the mixed salt in step 2 together with the crucible in a muffle furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min and keep it for 3 hours, cool down to 500°C at a rate of 5°C / min and then cool naturally.

[0046] Step 4: Take out the reaction product in step 3, place the reaction product in a beaker on a magnetic stirrer, stir at 50-80° C. for 30-60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com