Preparation method of Co3S4 nanosheet array modified by CeO2 nanoparticles

A nanosheet array and nanoparticle technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of easy agglomeration, lower utilization rate of active materials and cycle stability, and achieve simple and effective preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) The nickel foam is pretreated with hydrochloric acid and acetone respectively to remove impurities such as oxides and oil stains on the surface.

[0041] (2) Take 0.30g of Co(NO 3 ) 2 ·6H 2 O and 0.65 g of 2-methylimidazole were dissolved in 20 mL of deionized water respectively to obtain solution A and solution B. After fully mixing and stirring solution A and solution B, put in pretreated foamed nickel (2×3cm 2 ), stood at room temperature for 4h, took out, washed and dried to obtain Co-ZIF-L-NSAs / NF.

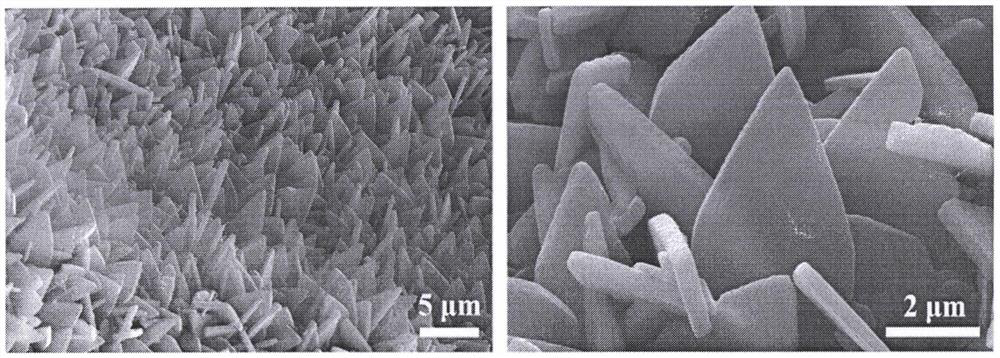

[0042] The scanning electron microscope picture of the Co-ZIF-L-NSAs / NF prepared above is as follows: figure 1 As shown, the right figure is a partially enlarged view of the left figure. From figure 1 It can be seen that Co-ZIF-L has a 2D nanosheet structure and a smooth surface.

[0043] (3) Put Co-ZIF-L-NSAs / NF into a solution of 0.15g thioacetamide dissolved in 50mL of absolute ethanol in advance for hydrothermal reaction, the reaction temperature is 120°...

Embodiment 2

[0052] (1) Take 0.30g of Co(NO 3 )2·6H 2 O and 0.65 g of 2-methylimidazole were dissolved in 20 mL of deionized water respectively to obtain solution A and solution B. After fully mixing and stirring the A and B solutions, put in the pretreated foamed nickel (2×3cm 2 ), stood at room temperature for 4h, took out, washed and dried to obtain Co-ZIF-L-NSAs / NF.

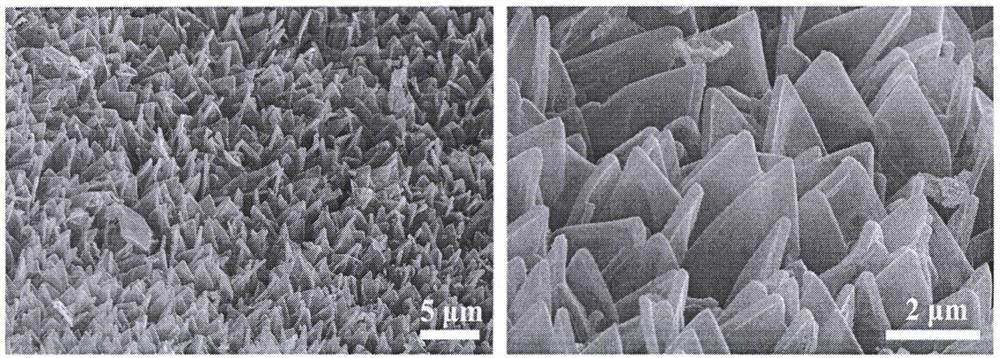

[0053] (2) Put Co-ZIF-L-NSAs / NF into a solution of 0.30 g of thioacetamide dissolved in 50 mL of absolute ethanol in advance for hydrothermal reaction, the reaction temperature is 130° C., and the reaction time is 6 h. After washing and drying, Co 3 S 4 -NSAs / NFs.

[0054] (3) Take 0.21g Ce(NO 3 ) 3 ·6H 2 O and 0.4 g hexamethylenetetramine, each dissolved in 2 0mL of ethanol to obtain solution A and solution B. Mix solution A and solution B thoroughly, put in Co 3 S 4 -NSAs / NF were subjected to solvothermal reaction, the reaction temperature was 180℃, and the reaction time was 6h. After washing and drying, Co...

Embodiment 3

[0059] (1) Take 0.31g of Co(NO 3 ) 2 ·6H 2 O and 0.66g of 2-methylimidazole were dissolved in 20mL deionized water respectively to obtain solution A and solution B. After fully mixing and stirring the A and B solutions, put in the pretreated foamed nickel (2×3cm 2 ), stood at room temperature for 4h, took out, washed and dried, and obtained Co-ZIF-L-NSAs / NF.

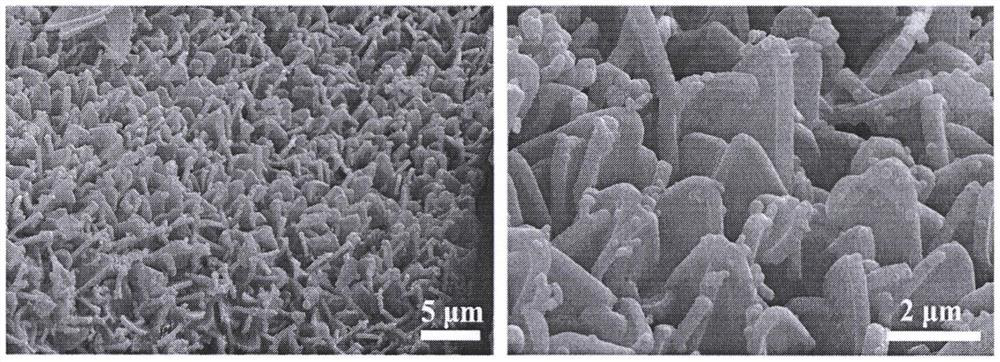

[0060] (2) Put Co-ZIF-L-NSAs / NF into a solution of 0.30 g of thioacetamide dissolved in 50 mL of absolute ethanol in advance for hydrothermal reaction at a reaction temperature of 120° C. and a reaction time of 4 h. After washing and drying, Co 3 S 4 -NSAs / NFs.

[0061] (3) Take 0.35g Ce(NO 3 ) 3 ·6H 2O and 0.667g of hexamethylenetetramine were each dissolved in 20mL of ethanol to obtain solution A and solution B. Mix solution A and solution B thoroughly, put in Co 3 S 4 -NSAs / NF were subjected to solvothermal reaction, the reaction temperature was 150℃, and the reaction time was 5h. After washing and drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com