Method for preparing Nano cerium oxdie, and application in chemical mechanical polishing chip of gallium arsenide

A technology of nano-cerium oxide and cerium nitrate, applied in chemical instruments and methods, polishing compositions containing abrasives, inorganic chemistry, etc., to achieve uniform distribution, low surface roughness, small surface and subsurface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

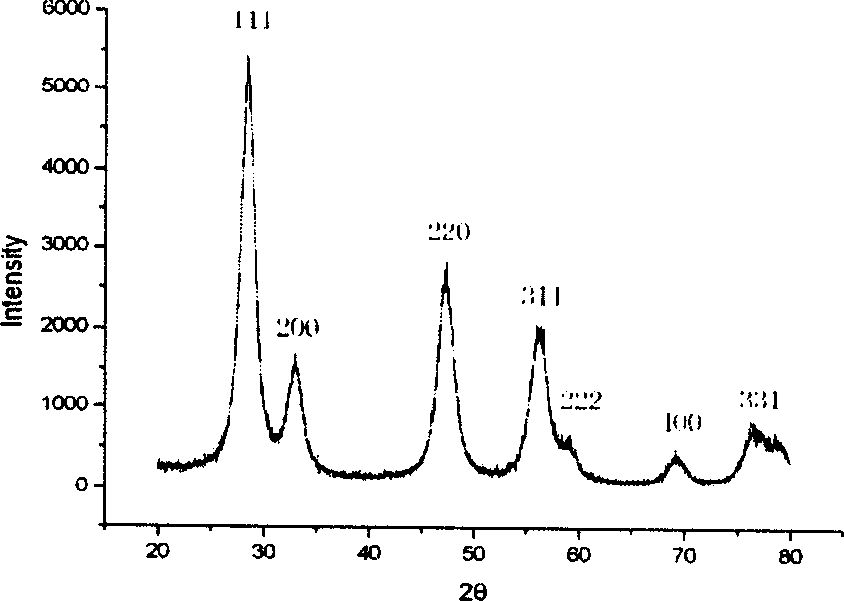

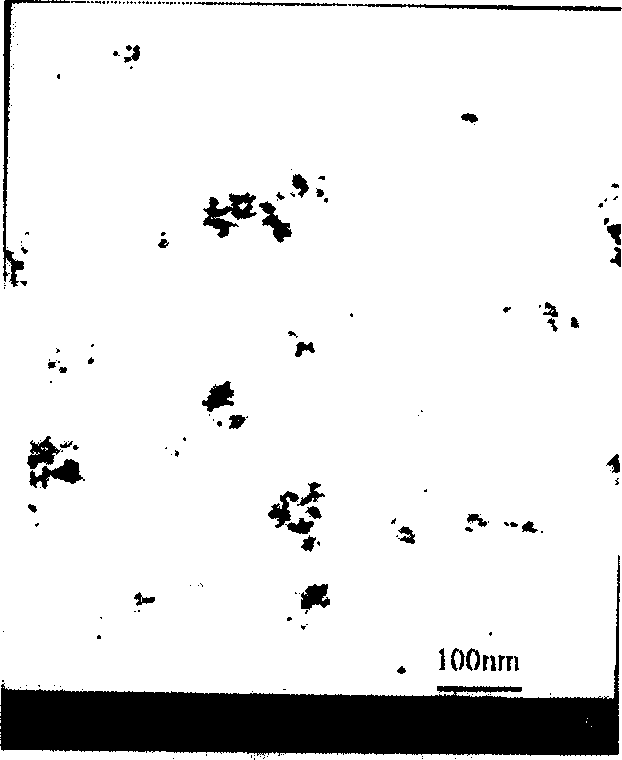

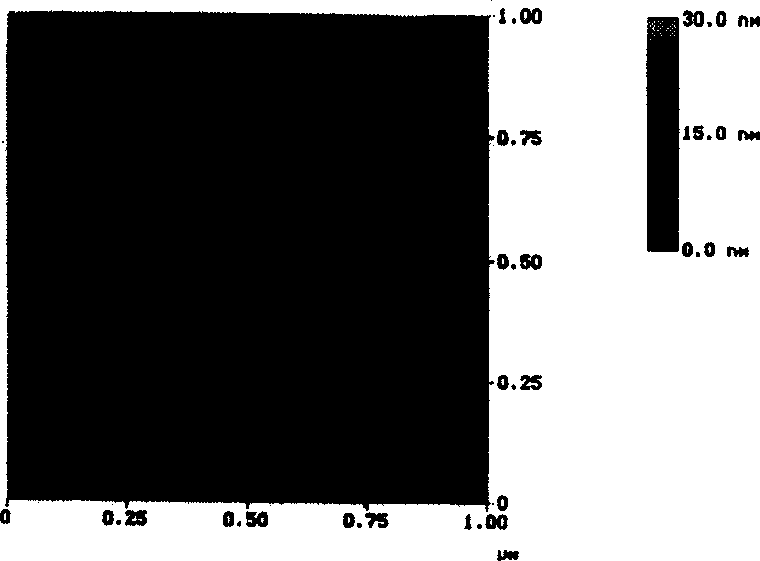

Image

Examples

Embodiment 1

[0013] Embodiment 1: take a certain amount of Ce (NO 3 ) 3 Dissolve in 150ml ethanol, then weigh a certain amount of HMT and dissolve it in 50ml distilled water, mix the two solutions and stir evenly, where [Ce 3+ ]=0.02mol / 1, HMT and Ce(NO 3 ) 3 The molar ratio is 20:1. Put the mixed solution into a constant temperature water bath at 75°C and heat it for 1 hour, take it out and let it cool and let it stand for 1 hour at room temperature, wash the precipitate with distilled water 3 times and absolute ethanol once, and put it in an oven at 70°C Dry in medium for 8 hours, take out and cool down, and grind the powder thoroughly. Take a certain amount of powder and configure it into a 100ml solution, the solute mass concentration is 1wt%, add the oxidizing agent H 2 o 2 The concentration is 20wt%, and KOH is added to adjust the pH value to 9. Under a certain polishing pressure (2N), rotational speed (200rmp) and time (25min), the GaAs wafer is polished using the American Bueh...

Embodiment 2

[0014] Embodiment 2: change solution parameter [Ce 3+ ] is 0.01mol / 1, HMT and Ce(NO 3 ) 3 The molar ratio is 40:1, the volume ratio of alcohol to water is 1:1, heated in a water bath at 70°C for 2h, aged for 1h, and dried at 60°C for 10h. Take an appropriate amount of powder to prepare a solution, the solute mass concentration is 2wt%, add oxidizing agent H 2 o 2 The concentration is 10wt%, the pH value is adjusted to 10 with KOH, and the subsequent polishing process is as in Example 1.

Embodiment 3

[0015] Embodiment 3: change solution parameter [Ce 3+ ] is 0.03mol / 1, HMT and Ce(NO 3 ) 3 The molar ratio is 30:1, the volume ratio of alcohol to water is 6:1, heated in a water bath at 80°C for 1h, aged for 2h, and dried at 80°C for 6h. Take an appropriate amount of powder to prepare a solution, the solute mass concentration is 5wt%, add oxidizing agent H 2 o 2 The concentration is 10wt%, the pH value is adjusted to 11 with KOH, and the subsequent polishing process is the same as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com