Preparation method and application of cerium dioxide with different defect degrees

A technology of ceria and defects, which is applied in the field of ceria preparation, can solve the problems of limitation, easy agglomeration, and easy recombination of photogenerated carriers, and achieve the effects of low cost, simple operation, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

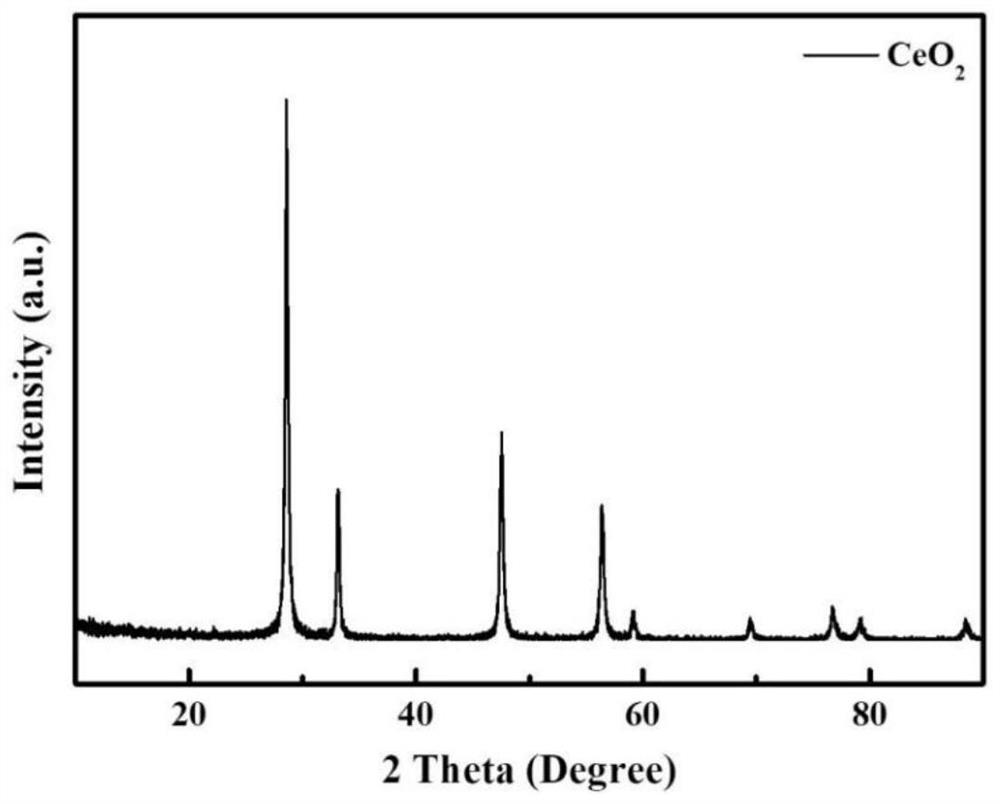

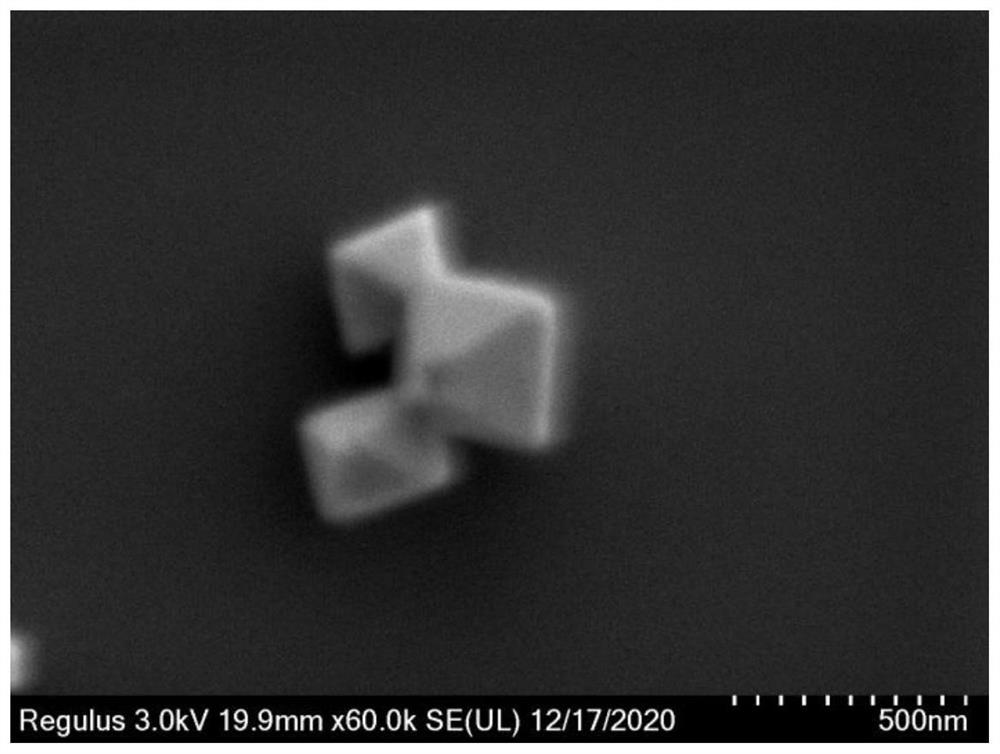

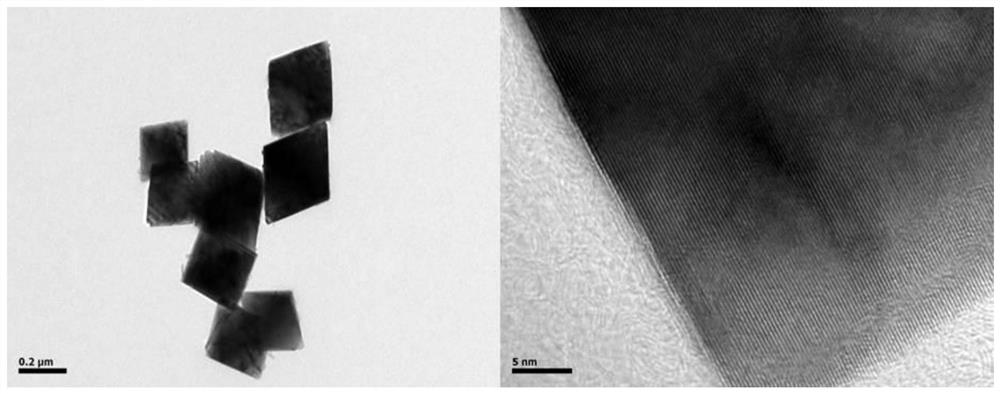

[0025] Method for preparing cerium oxide having different defects, such as Figure 1 - Figure 4 As shown, including the following steps:

[0026] A. Weigh 1.736 g of hexahydrate is placed in a beaker, add 20 ml of deionized water stir stock, weigh 0.0064 to 0.0067 g of trisodium phosphate is placed in a beaker, and 30 ml of deionized water stir stock is added;

[0027] B, pour a sufficiently mixed nitrate solution in the sodium phosphate solution, adding a magnetic aging for 30 min, and then add 10 mL of deionized water during aging. After the age is completed, the temperature is transferred to the reaction kettle, 170 ° C constant temperature 12h, the resulting precipitate Washing CEO 2 powder;

[0028] C, the CEO obtained 2 Powder is placed in PECVD, directly acting on the dry powder surface of 30 to 90 min, flow rate of 25 to 100 sccm, power 100W ~ 200W, and obtain a uniform uniform CEO with certain defects after discharging 2 catalyst.

[0029] Treatment of CEO with plasma flow...

Embodiment 1

[0032] D, weigh 100mg after processing CEO 2 Placed in the polytetrafluoroethylene liner, take 15 ml of methanol, add a magnet, and install high temperature and high pressure reactor, use CO 2 Gas purge 5min, then close the air valve, and turn off the intake valve after boiling to 4 MPa, turn on the temperature control and magnetic stirring, and the ring lamp, the xenon lamp working current is 14.5a, and the stage is raised to 140 ° C. The pressure of the kettle was finally raised to 7.5 MPa, and after 6 h, the cooling and lowering removal solution was detected by FID chromatography, such as Figure 5 Indicated.

[0033] In the 100mg CEO processed without step C defective 2 With 15 mL of methanol, the DMC content of the product was 0.33%.

Embodiment 2

[0035] It is called the CEO2 powder 50mg after step B, and placed in the center of the PECVD ring, and the N2 is passed to produce a nitrogen plasma flow directly to the CEO. 2 Surface 30 ~ 90min, flow rate 25 ~ 100Sccm, power 100W ~ 200W, after the discharge is completed, it obtains a uniform uniform CEO with certain defects. 2 The catalyst, finally produced DMC through step D photothermal catalysis. Meethanol conversion of the sample under different processing times Figure 5 .

[0036] It can be seen that the methanol conversion will increase as the power (time, flow rate) increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com