Modified perovskite negative electrode material for directly electrolyzing pure CO2 at high temperature

A cathode material, perovskite technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of easy carbon deposition, metal particles are easy to sinter and grow, easy to be oxidized, etc., to improve performance and resist carbon deposition and oxygen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

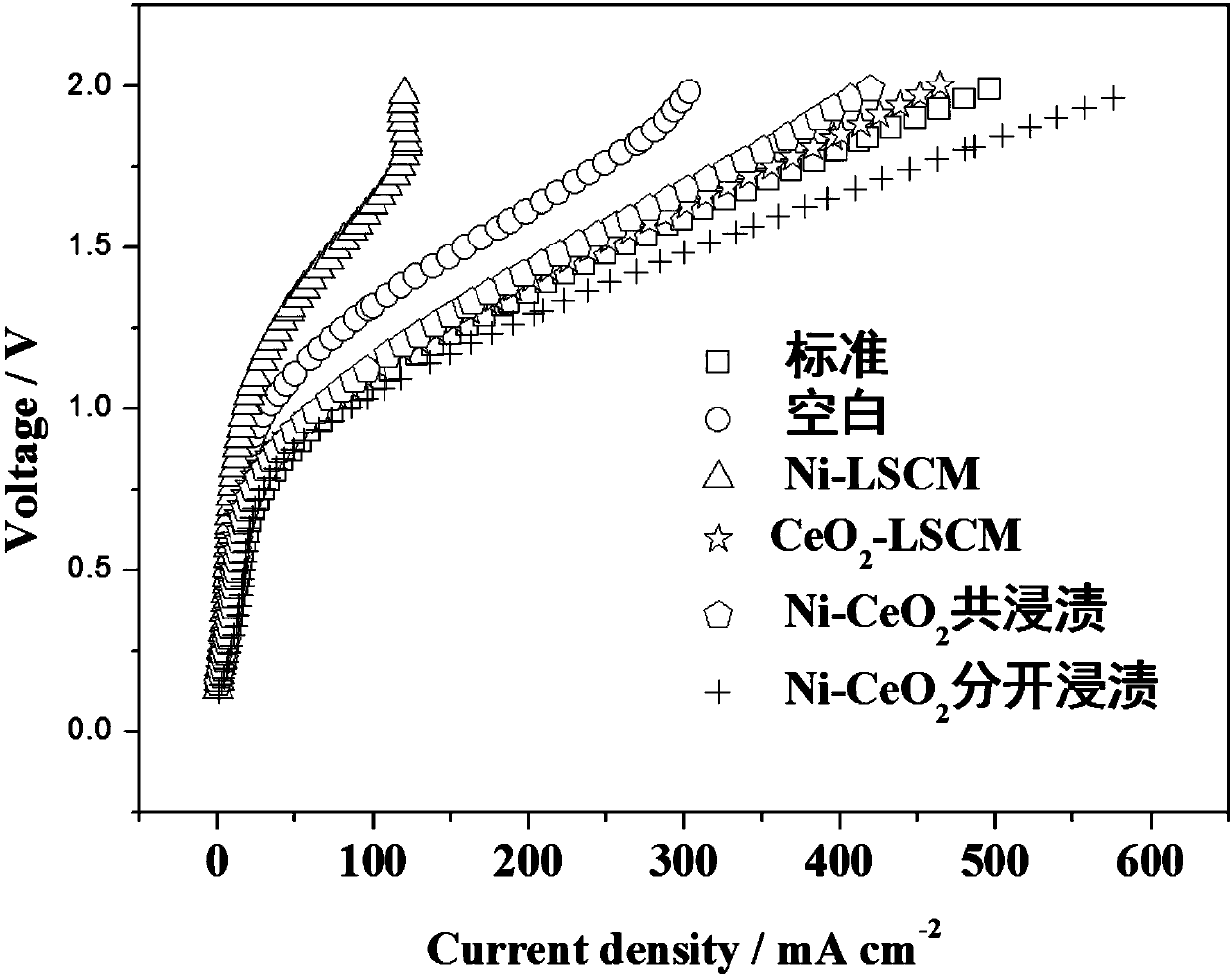

Embodiment 1

[0026] A high-temperature direct electrolysis of pure CO 2 The modified perovskite cathode material, taking LSCM perovskite cathode material as an example, the specific preparation method is as follows:

[0027] (1) Preparation of LSCM cathode: LSCM (La 0.75 Sr 0.25 Cr 0.5 mn 0.5 o 3-δ ) powder, GDC (Gd 0.1 Ce 0.9 o 1.95 ) according to the weight ratio of 1:1, mixed evenly in a mortar, adding terpineol solution to prepare a slurry, scraped it on the YSZ electrolyte, and placed it in a muffle furnace for 3 hours at 1100°C;

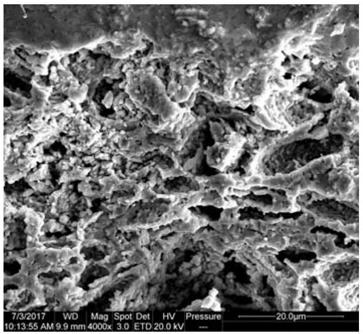

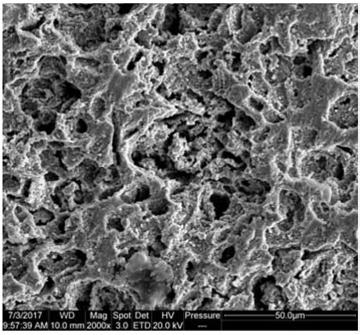

[0028] (2) Preparation of LSCM electrode skeleton: Mix LSCM powder and GDC in a mortar at a weight ratio of 1:1, add 15% spherical graphite as a pore-forming agent, add terpineol solution to prepare a slurry, and scrape it on On the YSZ electrolyte, place it in a muffle furnace for 3 hours at 1100°C;

[0029] (3) Preparation of Ni-CeO 2 Separately impregnate the modified LSCM cathode: prepare ~0.1mol L separately -1 Ni(NO 3 ) 2 solution and ~1....

Embodiment 2

[0044] A high-temperature direct electrolysis of pure CO 2 The modified perovskite cathode material, taking LSCM perovskite cathode material as an example, the specific preparation method is as follows:

[0045] (1) Preparation of LSCM cathode: LSCM (La 0.75 Sr 0.25 Cr 0.5 mn 0.5 o 3-δ ) powder, GDC (Gd 0.1 Ce 0.9 o 1.95 ) according to the weight ratio of 1:1, mixed evenly in a mortar, adding terpineol solution to prepare a slurry, scraped it on the YSZ electrolyte, and placed it in a muffle furnace for 3 hours at 1100°C;

[0046] (2) Preparation of LSCM electrode skeleton: Mix LSCM powder and GDC in a mortar at a weight ratio of 1:1, add 15% spherical graphite as a pore-forming agent, add terpineol solution to prepare a slurry, and scrape it on On the YSZ electrolyte, place it in a muffle furnace for 3 hours at 1100°C;

[0047] (3) Preparation of Ni-CeO 2 Separately impregnate the modified LSCM cathode: prepare ~0.1mol L separately -1 Ni(NO 3 ) 2 solution and ~1....

Embodiment 3

[0051] A high-temperature direct electrolysis of pure CO 2 The modified perovskite cathode material, taking LSCM perovskite cathode material as an example, the specific preparation method is as follows:

[0052] (1) Preparation of LSCM cathode: LSCM (La 0.75 Sr 0.25 Cr 0.5 mn 0.5 o 3-δ ) powder, GDC (Gd 0.1 Ce 0.9 o 1.95 ) according to the weight ratio of 1:1, mixed evenly in a mortar, adding terpineol solution to prepare a slurry, scraped it on the YSZ electrolyte, and placed it in a muffle furnace for 3 hours at 1100°C;

[0053] (2) Preparation of LSCM electrode skeleton: Mix LSCM powder and GDC in a mortar at a weight ratio of 1:1, add 15% spherical graphite as a pore-forming agent, add terpineol solution to prepare a slurry, and scrape it on On the YSZ electrolyte, place it in a muffle furnace for 3 hours at 1100°C;

[0054] (3) Preparation of Ni-CeO 2 Separately impregnate the modified LSCM cathode: prepare ~0.1mol L separately -1 Ni(NO 3 ) 2 solution and ~1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com