Anti-corrosion photovoltaic cable coating and preparation method thereof

A photovoltaic cable and anti-corrosion technology, applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve problems such as difficulty in fully exerting anti-corrosion performance and enhancement effect, poor dispersion and compatibility, and limited use effect, etc. Achieve excellent chemical stability, improved dispersion and compatibility, and good reinforcement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

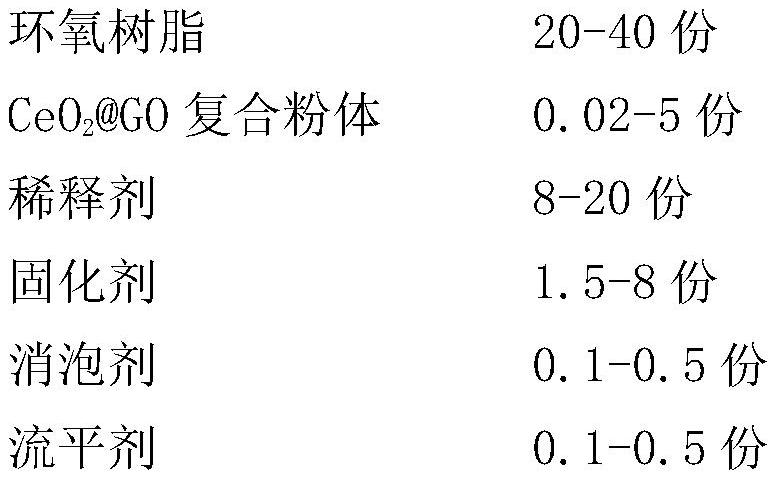

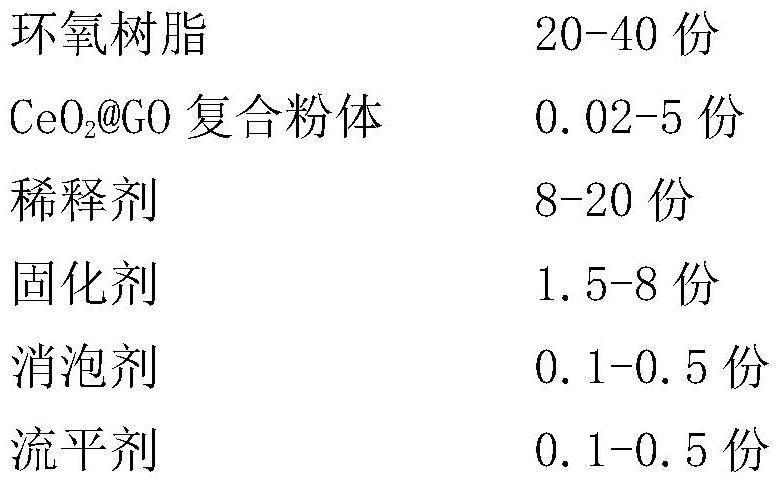

[0023] An anti-corrosion photovoltaic cable coating, comprising the following components in parts by weight: 20 parts of epoxy resin, CeO 2 0.02 parts of @GO composite powder, 8 parts of diluent acetone, 1.5 parts of acid anhydride curing agent, 0.1 part of silicone defoamer, 0.1 part of polyether modified organosiloxane leveling agent.

[0024] Among them, the CeO 2 The preparation of @GO composite powder includes the following steps:

[0025] a) Graphene oxide (GO) was synthesized by the improved Hummers method, and the specific operation was as follows: mix graphite powder and sodium nitrate, add concentrated sulfuric acid, stir at a temperature of 4°C for 30min, and then slowly add potassium permanganate, wherein The proportion of graphite powder, sodium nitrate, concentrated sulfuric acid and potassium permanganate is 2g: 1g: 100mL: 10g, continue to stir for 2 hours to make it evenly mixed, and move the mixed reactants into a preheated 35°C constant temperature water bat...

Embodiment 2

[0030]An anti-corrosion photovoltaic cable coating, comprising the following components in parts by weight: 40 parts of epoxy resin, CeO 2 5 parts of @GO composite powder, 20 parts of diluent ethanol, 8 parts of amine curing agent, 0.5 part of silicone defoamer, 0.5 part of polyether modified organosiloxane leveling agent.

[0031] Among them, the CeO 2 The preparation of @GO composite powder includes the following steps:

[0032] a) adopt improved Hummers method to synthesize and obtain graphene oxide (GO), concrete operation is the same as embodiment 1;

[0033] b) For nano-CeO 2 The surface is modified, in which the silane coupling agent KH550 and nano-CeO 2 The mass ratio is 1:1, and other operations are with embodiment 1;

[0034] c) Preparation of CeO 2 @GO composite powder, the specific operation is the same as in Example 1;

[0035] The preparation method of a kind of anti-corrosion photovoltaic cable coating comprises the following steps: weighing epoxy resin, C...

Embodiment 3

[0037] An anti-corrosion photovoltaic cable coating, comprising the following components in parts by weight: 30 parts of epoxy resin, CeO 2 2.5 parts of @GO composite powder, 14 parts of diluent acetone, 5 parts of anhydride curing agent, 0.3 parts of silicone defoamer, and 0.6 parts of polyether modified organosiloxane leveling agent.

[0038] Among them, the CeO 2 The preparation of @GO composite powder includes the following steps:

[0039] a) adopt improved Hummers method to synthesize and obtain graphene oxide (GO), concrete operation is the same as embodiment 1;

[0040] b) For nano-CeO 2 The surface is modified, and the silane coupling agent is KH550 and nano-CeO 2 The mass ratio is 0.6:1, and other operations are with embodiment 1;

[0041] c) Preparation of CeO 2 @GO composite powder, the specific operation is the same as in Example 1;

[0042] The preparation method of a kind of anti-corrosion photovoltaic cable coating comprises the following steps: weighing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com