Catalyst for catalytically combusting chlorine-containing organic substance and preparation method thereof

A catalytic combustion and catalyst technology, applied in combustion methods, combustion types, incinerators, etc., can solve problems such as limited catalytic activity, and achieve the effects of improving catalytic performance, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

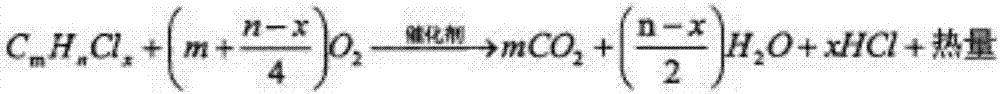

Method used

Image

Examples

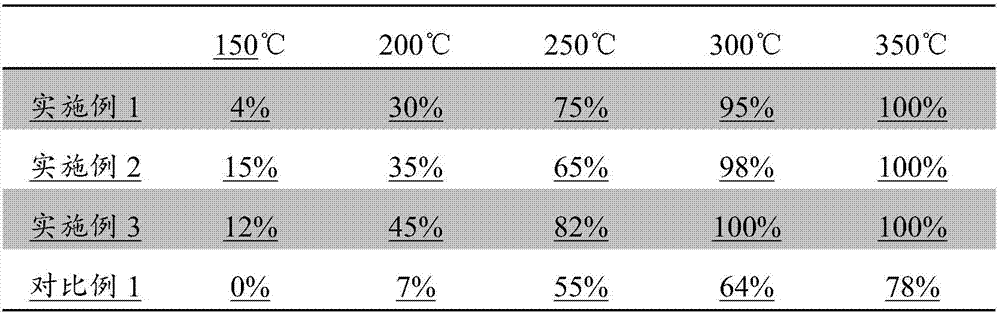

Embodiment 1

[0020] 11.6 g of cerium nitrate and 0.24 g of sodium chloride were dissolved in 100 mL of water, then 20 g of CNTS nanosheets were added to the solution, and the mixture was kept stirring for 30 minutes. The mixture was then transferred to an autoclave and heated to 130°C and maintained at this temperature for 24 hours. Filter, then dry the solid product at 60°C overnight, and finally roast in air at high temperature, press into tablets, and sieve (70-80 mesh) to obtain 23gNa-CeO 2 / CNTS catalyst, where CeO 2 The mass accounts for 30% of the catalyst, and Na accounts for 0.5% of the catalyst.

Embodiment 2

[0022] 11.6 g of cerium nitrate and 0.35 g of potassium chloride were dissolved in 100 mL of water, then 20 g of CNTS nanosheets were added to the solution, and the mixture was kept stirring for 30 minutes. The mixture was then transferred to an autoclave and heated to 130°C and maintained at this temperature for 24 hours. Filter, then dry the solid product overnight at 60°C, and finally roast it in the air at high temperature, press into tablets, and sieve (70-80 mesh) to obtain 25g K-CeO 2 / CNTS catalyst, where CeO 2 The mass accounts for 30% of the catalyst, and the K accounts for 0.6% of the catalyst.

Embodiment 3

[0024] 11.6 g of cerium nitrate and 0.67 g of cesium chloride were dissolved in 100 mL of water, then 20 g of CNTS nanosheets were added to the solution, and the mixture was kept stirring for 30 minutes. The mixture was then transferred to an autoclave and heated to 130°C and maintained at this temperature for 24 hours. Filter, then dry the solid product overnight at 60°C, and finally roast it in air at high temperature, press it into tablets, and sieve (70-80 mesh) to obtain 23.5g Na-CeO 2 / CNTS catalyst, where CeO 2 The mass accounts for 30% of the catalyst, and the CS accounts for 0.7% of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com