Method for synthesizing CeO2 nano spherical particles by a molten salt method

A technology of spherical particles and synthesis methods, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as low uniformity of shape, poor dispersion, and poor size controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Ce(NO 3 ) 3 , KCl and LiCl were mixed in a ratio of 2:50:30, and ground with an agate mortar to obtain a uniformly mixed solid mixture; the obtained mixture was collected in an alumina crucible and then put into a muffle furnace, and pressed The temperature was raised to 540°C at a rate of 5°C / min, roasted for 4 h, and cooled naturally; the reacted product was soaked in deionized water to desalinate, and filtered with suction to obtain a yellow solid; the obtained yellow solid was taken out to a centrifuge tube and used to Centrifuged and washed several times with deionized water, dried in vacuum at 60°C to obtain yellow CeO 2 nanoparticles.

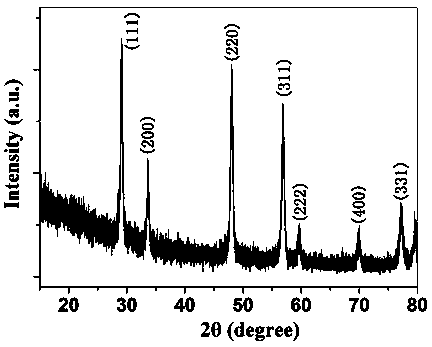

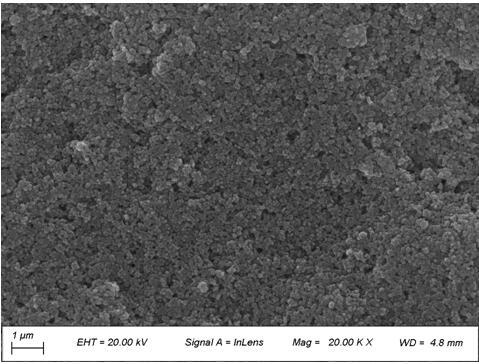

[0027] XRD test results show that the product is pure phase CeO 2 compound ( figure 1 ), the results of scanning electron microscopy showed that ( figure 2 ), the synthesized CeO 2 The nanoparticle samples have uniform morphology and good dispersion, with diameters ranging from 60 to 100 nm.

Embodiment 2

[0029] Will Ce 2 (CO 3 ) 3 , KCl and LiCl were mixed in a ratio of 2:50:30, and ground with an agate mortar to obtain a uniformly mixed solid mixture; the obtained mixture was collected in an alumina crucible and then put into a muffle furnace, and pressed The temperature was raised to 660°C at a rate of 5°C / min, roasted for 4 h, and cooled naturally; the reacted product was soaked in deionized water to desalinate, and filtered with suction to obtain a yellow solid; the obtained yellow solid was taken out to a centrifuge tube and used to Centrifuged and washed several times with deionized water, dried in vacuum at 60°C to obtain yellow CeO 2 nanoparticles.

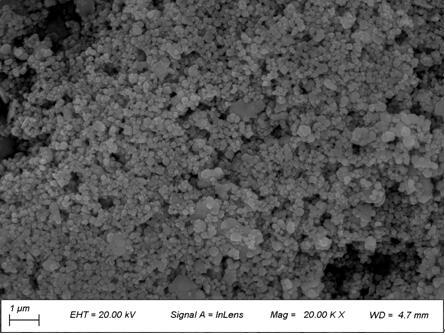

[0030] image 3 It is the CeO prepared in this example 2 Scanning electron micrograph of the sample, it can be seen that the synthesized product CeO 2 It is a spherical nanoparticle with a diameter of 100-400 nm.

Embodiment 3

[0032] Will Ce 2 (CO 3 ) 3 , KCl and LiCl were mixed in a ratio of 2:50:30, and ground with an agate mortar to obtain a uniformly mixed solid mixture; the obtained mixture was collected in an alumina crucible and then put into a muffle furnace, and pressed The temperature was raised to 780°C at a rate of 5°C / min, roasted for 3 h, and cooled naturally; the reacted product was soaked in deionized water to desalinate, and filtered with suction to obtain a yellow solid; the obtained yellow solid was taken out to a centrifuge tube and used to Centrifuged and washed several times with deionized water, dried in vacuum at 60°C to obtain yellow CeO 2 nanoparticles. Figure 4 It is the CeO prepared in this example 2 Scanning electron micrograph of the sample, it can be seen that the synthesized product CeO 2 It is a spherical nanoparticle with a diameter of 600-1000 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com