Polyhedral hollow core-shell structure MxM'3-xO4@CeO2 composite material and preparation method thereof

A polyhedral structure, core-shell structure technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., to achieve the effect of mild conditions and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

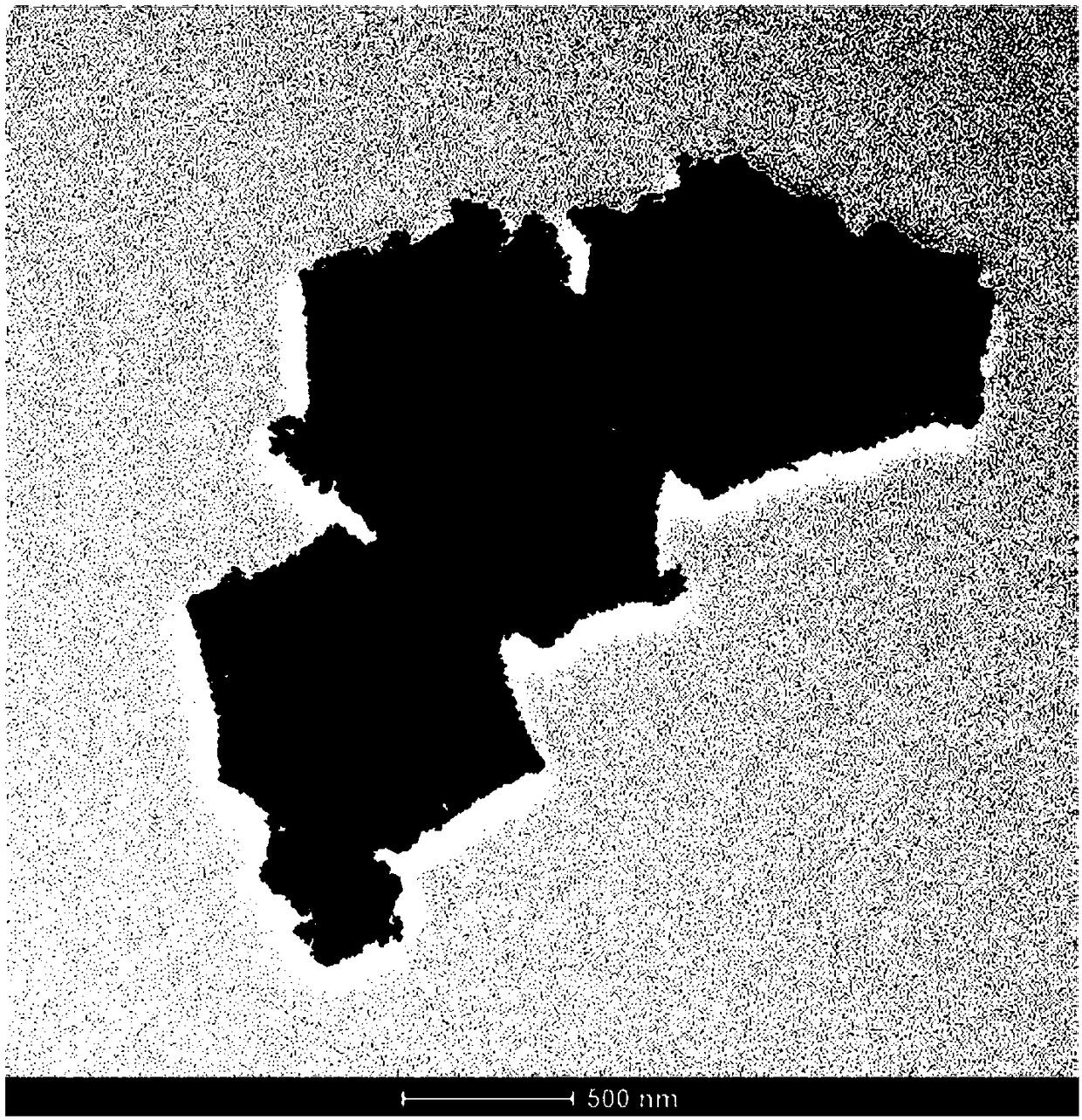

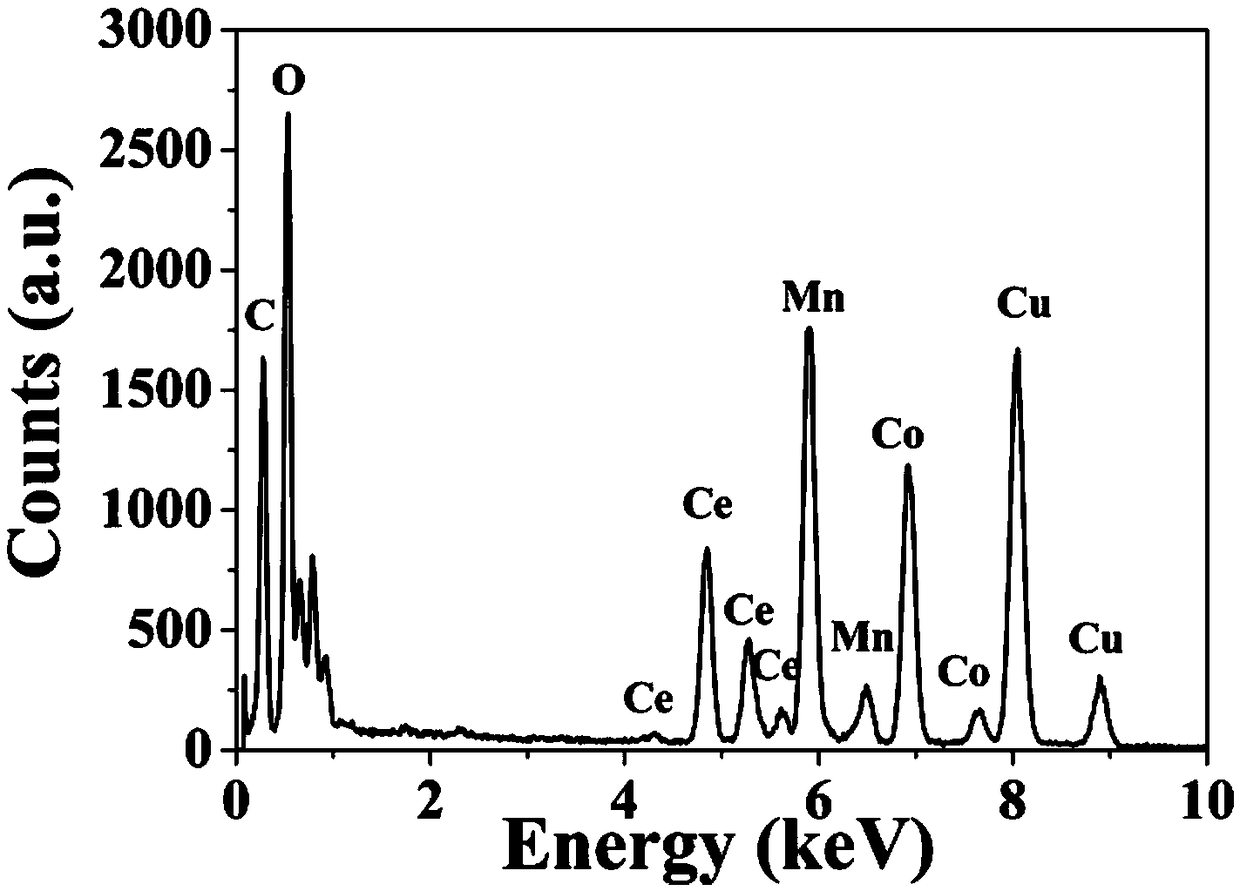

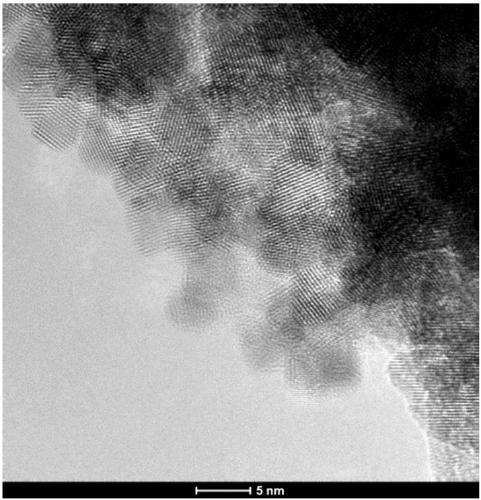

[0033] A polyhedral hollow core-shell Zn x co 3-x o 4 @CeO 2 The preparation method of the composite material, the detailed flow diagram is shown in Figure 4 , including the following steps:

[0034] (1) Synthesis of Zn, Co-MOFs polyhedral crystal structure materials:

[0035] Weigh 2.97g (10mmol) of zinc nitrate hexahydrate and 5.82g (20mmol) of cobalt nitrate hexahydrate according to the molar ratio of Zn:Co 1:2, and dissolve them in 300mL of methanol to form solution A, and weigh 9.84g of 2-methylimidazole g (0.12mol) was dissolved in 100mL of methanol to form solution B, and solution A was added dropwise to solution B under the action of magnetic stirring, and after stirring continuously for 30min, it was aged at room temperature for 24h, and the resulting precipitate was filtered , washed with methanol, and dried to obtain Zn, Co-MOFs polyhedral structure materials.

[0036] (2)Zn x co 3-x o 4 Synthesis of Polyhedral Hollow Structure Materials:

[0037] Put the...

Embodiment 2

[0044] A polyhedral hollow core-shell Zn x co 3-x o 4 @CeO 2 The preparation method of the composite material, the detailed flow diagram is shown in Figure 4 , including the following steps:

[0045] (1) Synthesis of Zn, Co-MOFs polyhedral crystal structure materials:

[0046] Weigh 1.78g (6mmol) of zinc nitrate hexahydrate and 6.98g (24mmol) of cobalt nitrate hexahydrate according to the molar ratio of Zn:Co 1:4, and dissolve them in 300mL methanol to form solution A, and weigh 12.3 g of 2-methylimidazole g (0.15mol) was dissolved in 100mL of methanol to form solution B, and solution A was added dropwise to solution B under the action of magnetic stirring, and after continuous stirring for 30min, it was aged at room temperature for 24h, and the resulting precipitate was filtered , washed with methanol, and dried to obtain Zn, Co-MOFs polyhedral structure materials.

[0047] (2)Zn x co 3-x o 4 Synthesis of Polyhedral Hollow Structure Materials:

[0048] Put the porc...

Embodiment 3

[0054] A polyhedral hollow core-shell Zn x co 3-x o 4 @CeO 2 The preparation method of the composite material, the detailed flow diagram is shown in Figure 5 , including the following steps:

[0055] (1) Synthesis of Zn-MOF@Co-MOF polyhedral core-shell structure materials:

[0056] ① Weigh 2.97g (10mmol) of zinc nitrate hexahydrate and dissolve it in 300mL of methanol to form solution A 1 , weighed 3.28g (40mmol) of 2-methylimidazole, dissolved in 100mL of methanol to form solution B 1 , under the action of magnetic stirring, the solution A 1 Add solution B dropwise 1 , after stirring continuously for 30 min, it was aged in a 70° C. water bath for 4 h, and the obtained precipitate was filtered, washed with methanol, and dried to obtain Zn-MOF polyhedral seed crystals. ②Weigh 1.164g (4mmol) of cobalt nitrate hexahydrate and dissolve it in 150mL methanol to form solution A 2 ; Weigh 1.64g (20mmol) of 2-methylimidazole and 1.6g of the Zn-MOF polyhedral seed obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com