Double-functional perovskite/cerium oxide composite oxygen catalyst of bionic structure

A composite catalyst, oxygen catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst activation/preparation, etc., can solve the limitations of zinc-air battery discharge kinetic performance, perovskite Problems such as low catalytic activity of mineral oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

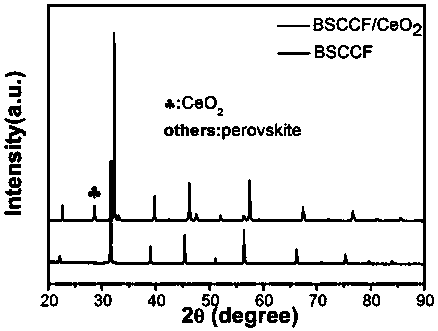

[0025] With 0.271g cerium nitrate Ce(NO) 3 ·6H 2 O is Ce source, 1.498g barium hydroxide Ba(OH) 2 ·8H 2 O is barium source, 1.005g strontium nitrate Sr(NO 3 ) 2 As a strontium source, 2.328g cobalt nitrate Co(NO) 3 ·6H 2 O is cobalt source, 0.808g iron nitrate Fe(NO 3 ) 3 9H 2 O is an iron source, 20ml dimethylformamide (DMF) is an organic solvent, and polyvinylpyrrolidone (PVP) of 12%wt is added and fully mixed and stirred to obtain an electrospinning polymer solution, which is prepared by an electrospinning method (Ba 0.5 Sr 0.5 ) 1- x Ce x co 0.8 Fe 0.2 o 3 The nanofibers are dried and roasted at a certain temperature, wherein a voltage of 15KV is applied to the electrospinning needle, a receiver is placed at a distance of 15CM from the needle, the advancing speed of the syringe pump is 0.1ml / h, the working temperature is 50°C, and the humidity is 28%. The fibers obtained by electrospinning were dried at 60 °C for 12 h, and then sintered in a muffle furnace ...

Embodiment 2

[0029] With 0.271g cerium nitrate Ce(NO) 3 ·6H 2 O is Ce source, 1.498g barium hydroxide Ba(OH) 2 ·8H 2 O is barium source, 1.005g strontium nitrate Sr(NO 3 ) 2 As a strontium source, 2.328g cobalt nitrate Co(NO) 3 ·6H 2 O is cobalt source, 0.808g iron nitrate Fe(NO 3 ) 3 9H 2 O is an iron source, 20ml dimethylformamide (DMF) is an organic solvent, and 12%wt of polyacrylonitrile (PAN) is added to fully mix and stir to obtain an electrospinning outer layer polymer solution, and 9%wt of polyethylene Pyrrolidone (PVP) was added with 10ml of alcohol and stirred thoroughly, and prepared by electrospinning (Ba 0.5 Sr 0.5 ) 1-x Ce x co 0.8 Fe 0.2 o 3 The nanotubes are dried and roasted at a certain temperature. The electrospinning needle is applied with a voltage of 15KV, and the receiver is placed at a distance of 15CM from the needle. h The working temperature is 50°C and the humidity is 28%. The fibers obtained by electrospinning are dried at 60°C for 12 hours, and...

Embodiment 3

[0033] With 0.271g cerium nitrate Ce(NO) 3 ·6H 2 O is Ce source, 1.498g barium hydroxide Ba(OH) 2 ·8H 2 O is barium source, 1.005g strontium nitrate Sr(NO 3 ) 2 As a strontium source, 2.328g cobalt nitrate Co(NO) 3 ·6H 2 O is cobalt source, 0.808g iron nitrate Fe(NO 3 ) 3 9H 2 O is an iron source, 20ml dimethylformamide (DMF) is an organic solvent, and polyvinylpyrrolidone (PVP) of 12%wt is added and fully mixed and stirred to obtain an electrospinning polymer solution, which is prepared by an electrospinning method (Ba 0.5 Sr 0.5 ) 1- x Ce x co 0.8 Fe 0.2 o 3 The nanofibers are dried and roasted at a certain temperature, wherein the electrospinning needle is applied with a voltage of 18KV, a receiver is placed at a distance of 17CM from the needle, the advance speed of the syringe pump is 0.1ml / h, the working temperature is 50°C, and the humidity is 28%. The fibers obtained by electrospinning were dried at 60 °C for 12 h, and then sintered in a muffle furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com