Preparation method of Cp*Co(CO)I2-loaded cobalt-doped zinc oxide photoanode nano array

A nano-array and photoanode technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as no related reports, and achieve good electron transfer efficiency, good photoelectrochemical performance, and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

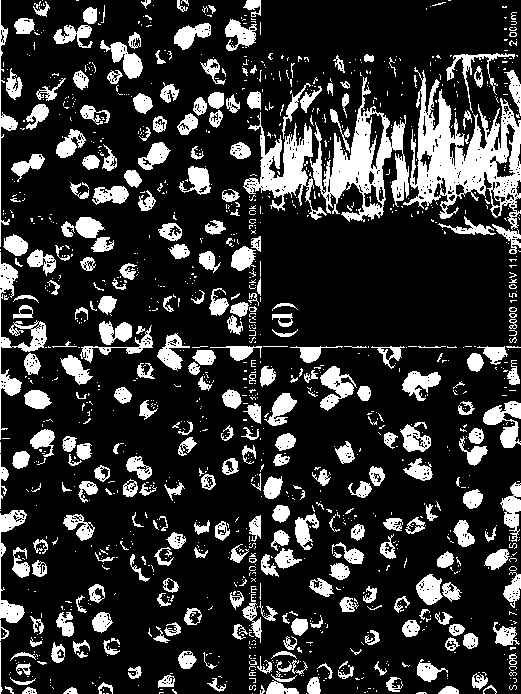

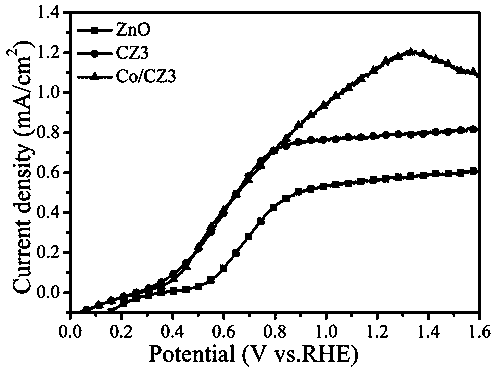

Embodiment 1

[0020] Take 10~200μL of 10mM zinc acetate ethanol solution and drop-coat it on the cleaned FTO substrate, 2500~3500 rpm for 30 seconds. Transfer to a muffle furnace, heat up to 300° C. for 2.5 hours for calcination over 40 minutes to obtain a zinc oxide seed layer. Put the above substrate into a polytetrafluoroethylene autoclave, add 0.01M Zn(NO 3 ) 2 ·6H 2 O and 0.01M hexamethylenetetramine, 80mL mixed solution with a molar ratio of 1:1, were hydrothermally reacted at 90°C for 6h to obtain ZnO photoanode nanoarrays. Cobalt nitrate with a molar ratio of Co / Zn=1% was added to the hydrothermal reaction solution, and CZ1 photoanode nanoarrays were obtained under the same conditions. The prepared Co-ZnO photoanode nanoarrays were immersed in Cp*Co(CO)I at room temperature in the dark 2 N,N-dimethylformamide solution for 10h, and finally washed with ethanol and water to obtain Co / CZ1 photoanode nanoarrays.

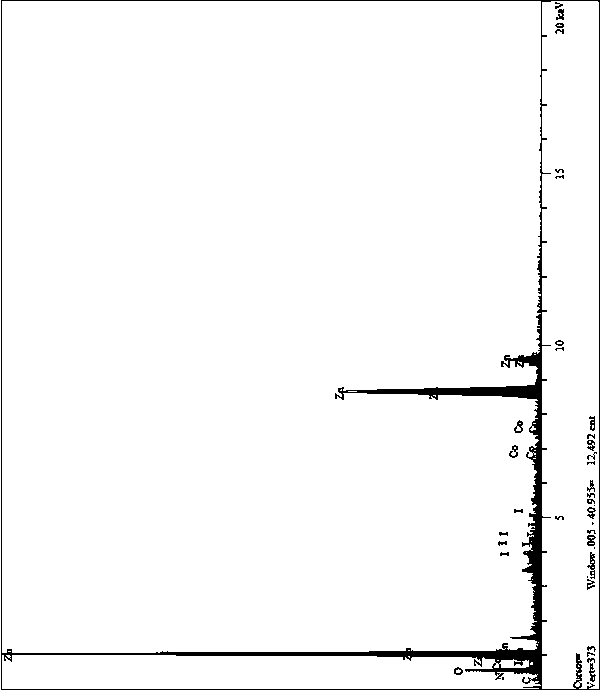

Embodiment 2

[0022] Take 10~200μL of 10mM zinc acetate ethanol solution and drop-coat it on the cleaned FTO substrate, 2500~3500 rpm for 30 seconds. Transfer to a muffle furnace, heat up to 300° C. for 2.5 hours for calcination over 40 minutes to obtain a zinc oxide seed layer. Put the above substrate into a polytetrafluoroethylene autoclave, add 0.05M Zn(NO 3 ) 2 ·6H 2 O and 0.05M hexamethylenetetramine, 80mL mixed solution with a molar ratio of 1:1, were hydrothermally reacted at 90°C for 6h to obtain ZnO photoanode nanoarrays. Cobalt nitrate with a molar ratio of Co / Zn=3% was added to the hydrothermal reaction solution, and CZ3 photoanode nanoarrays were obtained under the same conditions. The prepared Co-ZnO photoanode nanoarrays were immersed in Cp*Co(CO)I at room temperature in the dark 2 N,N-dimethylformamide solution for 10h, and finally washed with ethanol and water to obtain Co / CZ3 photoanode nanoarrays.

Embodiment 3

[0024] Take 10~200μL of 10mM zinc acetate ethanol solution and drop-coat it on the cleaned FTO substrate, 2500~3500 rpm for 30 seconds. Transfer to a muffle furnace, heat up to 300° C. for 2.5 hours for calcination over 40 minutes to obtain a zinc oxide seed layer. Put the above substrate into a polytetrafluoroethylene autoclave, add 0.25M Zn(NO 3 ) 2 ·6H 2 O and 0.25M hexamethylenetetramine, 80mL mixed solution with a molar ratio of 1:1, were hydrothermally reacted at 90°C for 6h to obtain ZnO photoanode nanoarrays. Cobalt nitrate with a molar ratio of Co / Zn=5% was added to the hydrothermal reaction solution, and the CZ5 photoanode nanoarray was obtained under the same conditions. The prepared Co-ZnO photoanode nanoarrays were immersed in Cp*Co(CO)I at room temperature in the dark 2 N,N-dimethylformamide solution for 10 h, and finally rinsed with ethanol and water to obtain Co / CZ5 photoanode nanoarrays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com