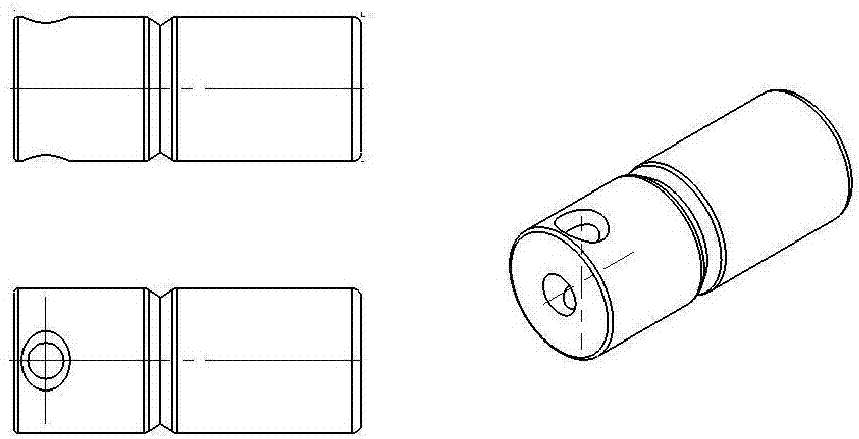

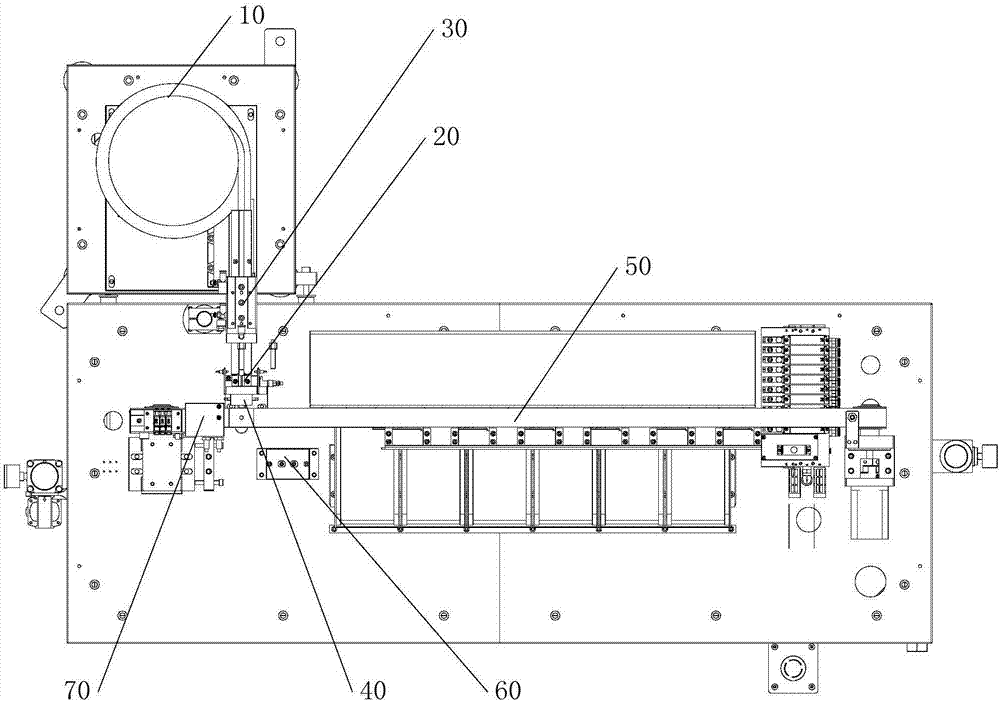

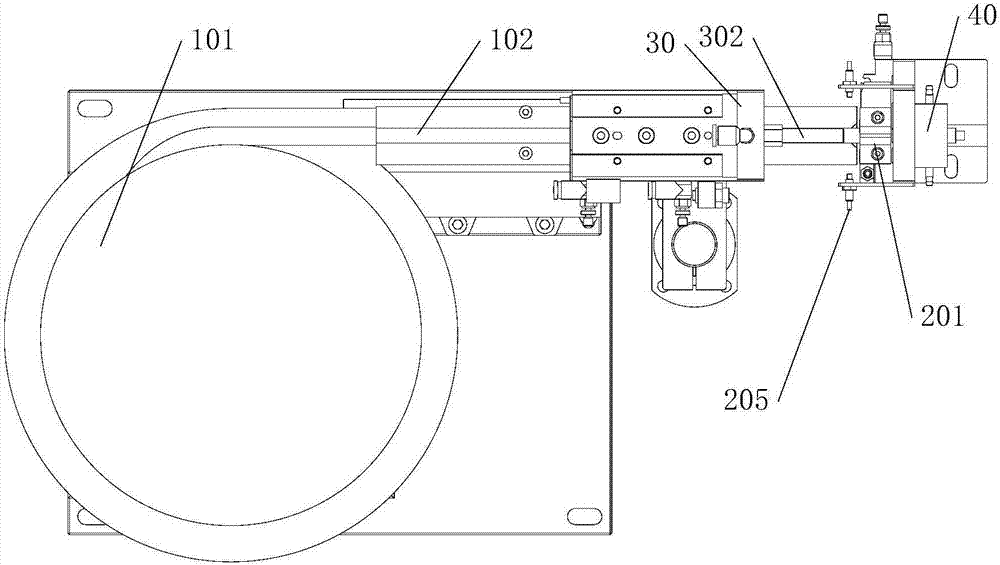

Work piece measuring device and measuring method

A technology for measuring equipment and workpieces, applied in the field of workpiece measuring equipment for piston pins, can solve the problems of complex structure, inability to sort and blank the piston pins, etc., and achieve the effect of not easy to jam, stable and efficient equipment, and improved flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] For the convenience of description, when assembling the components of the following systems, they can be assembled on the overall frame of each system. The frame plays a supporting role and the positioning of each component. If there is no special instruction, conventional Assembled in different ways, such as directly assembled to the frame, or assembled to the brackets, panels (horizontal or vertical), support columns, support platforms, etc. assembled on the frame, so the assembly relationship between each component and the frame will not be described in detail separately.

[0056]According to the needs of automatic control, corresponding sensors can be installed at the required positions. If there is no special instruction, a certain automatic control function can be realized without description in the following, such as in-position detection, displacement detection and other functions, all of which can be realized by setting sensors and control devices. Realization o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com