Ink fountain roller, ink distributing unit and ink distributing system of carving photogravure press

A technology for engraving gravure and ink fountain rollers, which is applied in the direction of gravure rotary printing machines, general parts of printing machinery, printing machines, etc., can solve the problems of easy damage to ink printing, poor ink saving effect, long ink path, etc. It is easy to ensure the accuracy of ink transfer, easy to maintain printing suitability, and not easy to jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

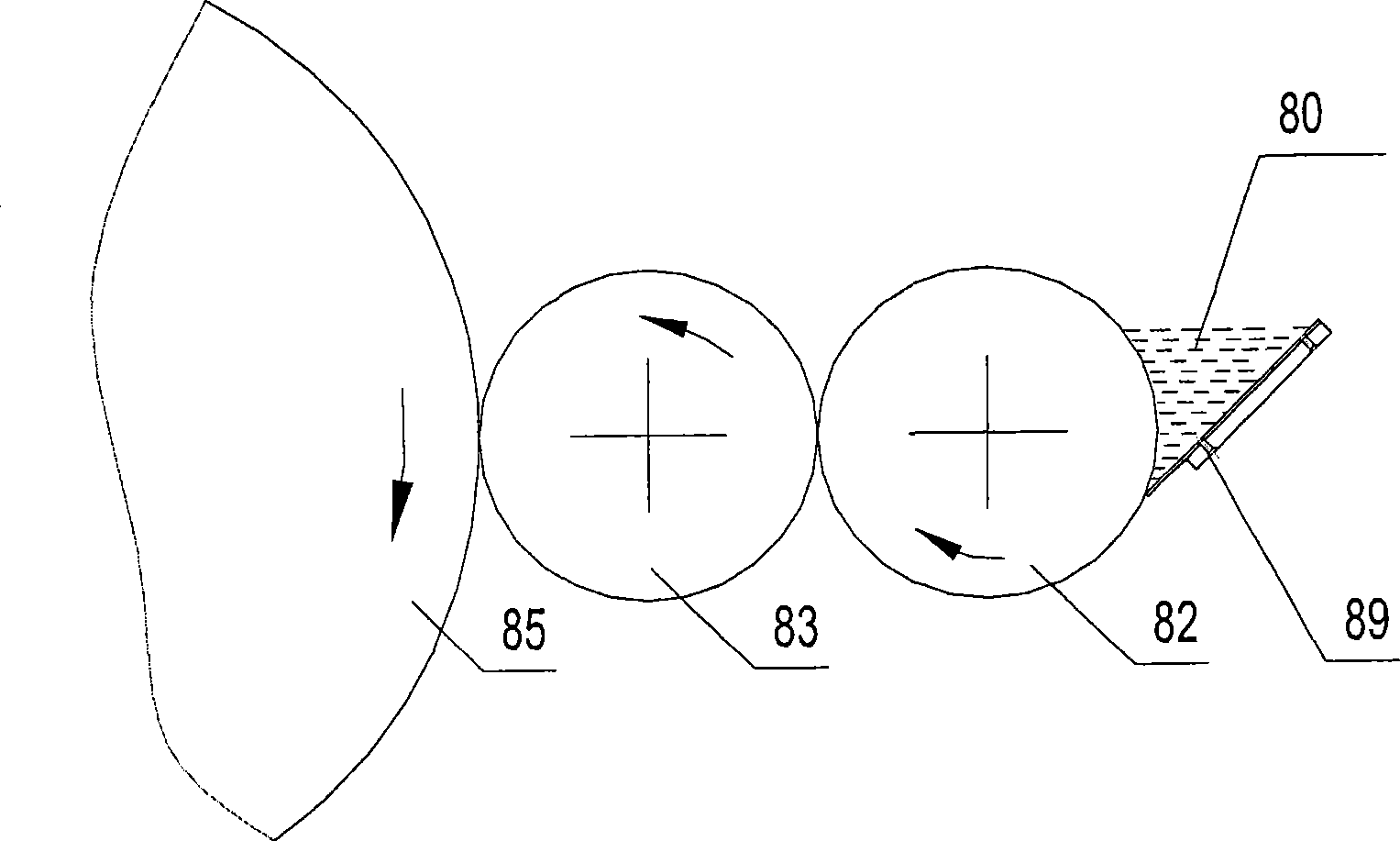

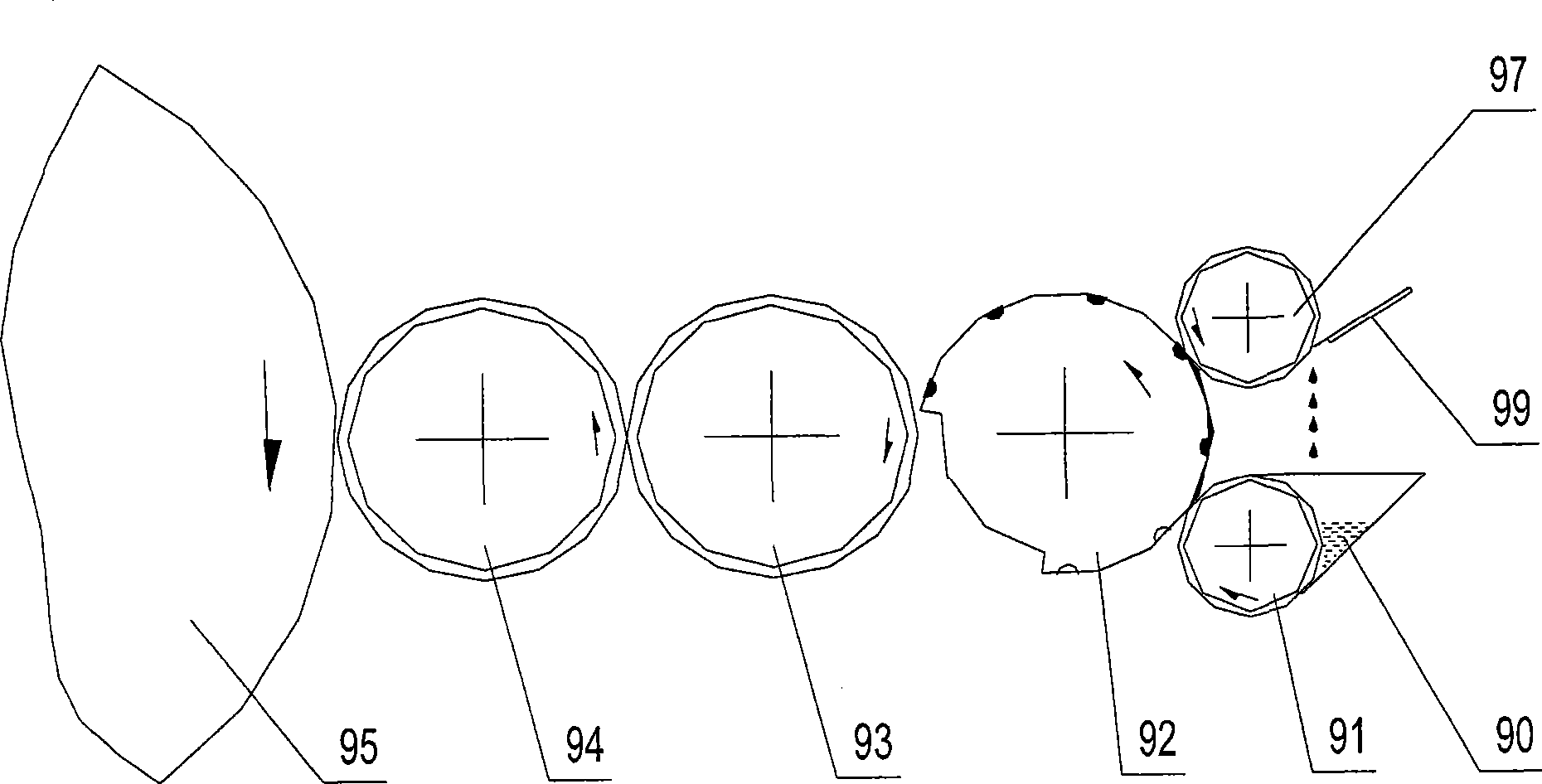

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0023] The present invention proposes a kind of ink fountain roller that engraving gravure printing machine is used at first, please refer to Figure 5 As shown, the ink fountain roller is a concave ink outlet roller 12 with pseudo-texture 120 on the surface, and the pseudo-texture 120 corresponds to the gravure pattern 150 .

[0024] In a specific embodiment of the present invention, the pseudo-texture 120 is enlarged and deepened according to a certain ratio according to the printing plate pattern 150 , so that the pseudo-texture concave mold is also different in depth and thickness.

[0025] Figure 5 It is a structural schematic diagram of a specific embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com