System and method for negative-pressure ink supply of rigid printed circuit board jet printing

An ink supply and negative pressure technology, applied in printing and other directions, can solve the problems of unstable negative pressure of the nozzle and bubbles in the pipeline, and achieve the effect of high ink supply stability and short ink path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

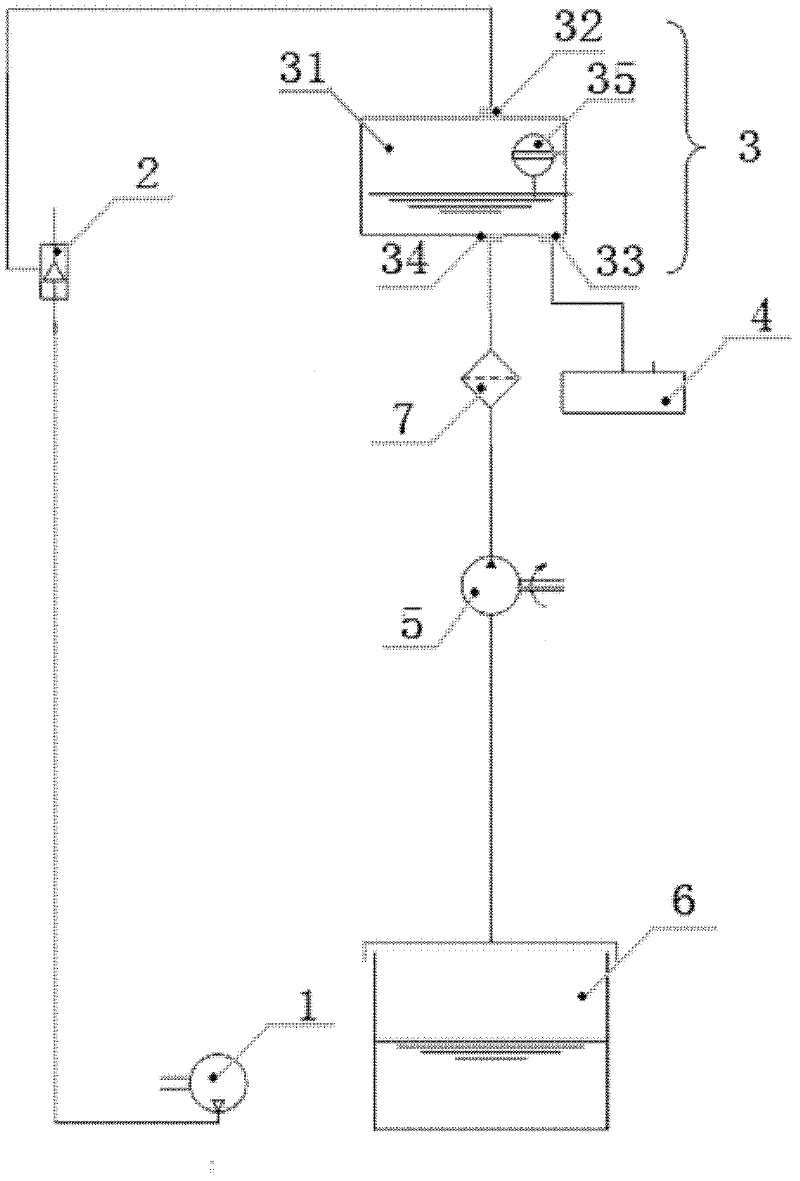

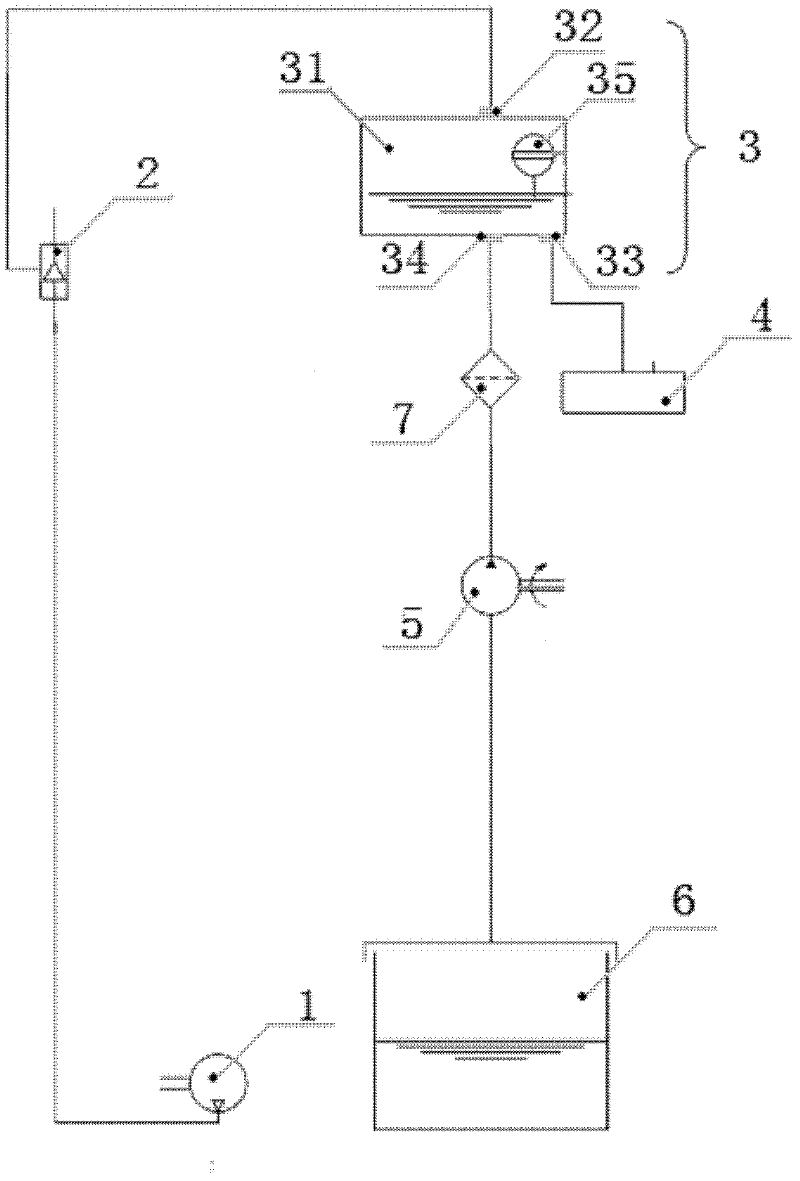

[0021] Such as figure 1 As shown, the negative pressure ink supply system of the present invention includes a vacuum pump 1, a vacuum generator 2, an ink cartridge 3, a nozzle 4, an ink bottle 5, an ink supply pump 6 and a filter 7;

[0022] The ink cartridge 3 includes a box body 31, an air vent 32, an ink outlet 33, an ink supply port 34 and a float switch 35, the air vent 32 is located at the top of the box body 31, and the ink outlet 33 is located at the top of the box The lower part of the body 31, the ink supply port 34 is located in the middle of the box body 31, which is basically equal to the required liquid level, and the float switch 35 is arranged in the box body 31;

[0023] The suction port of the vacuum pump 1 communicates with the air, the exhaust port of the vacuum pump 1 is connected with the air supply port of the vacuum generator 2, and the vacuum port of the vacuum generator 2 is connected with the air port 32, The ink outlet 33 is connected to the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com