Special three-way electro hydraulic servo valve for down-pressing system of rolling mill

A technology of electro-hydraulic servo valve and pressing system, which is applied in the direction of metal rolling stand, metal rolling mill stand, servo motor assembly, etc., to achieve the effect of simple structure, low processing cost and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

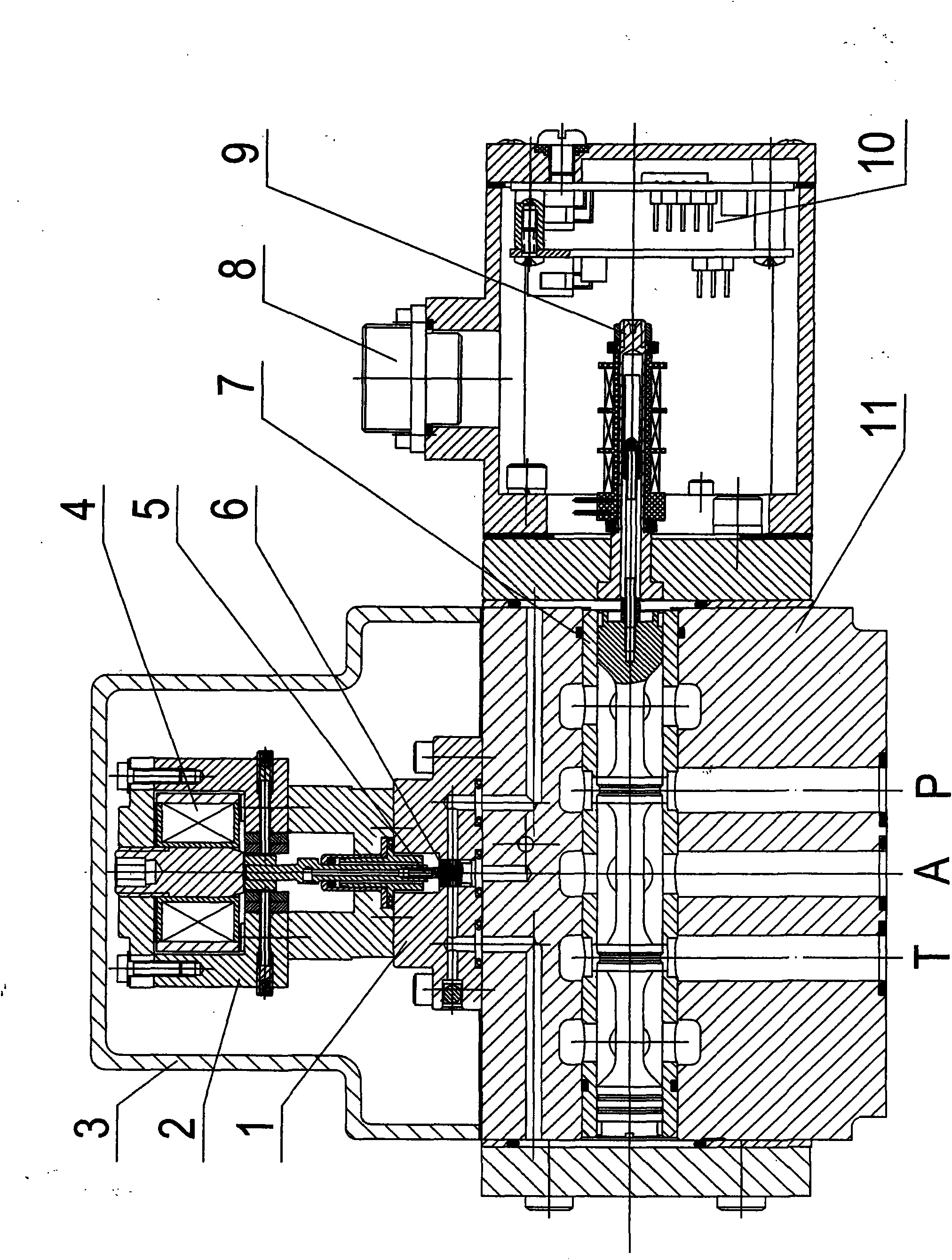

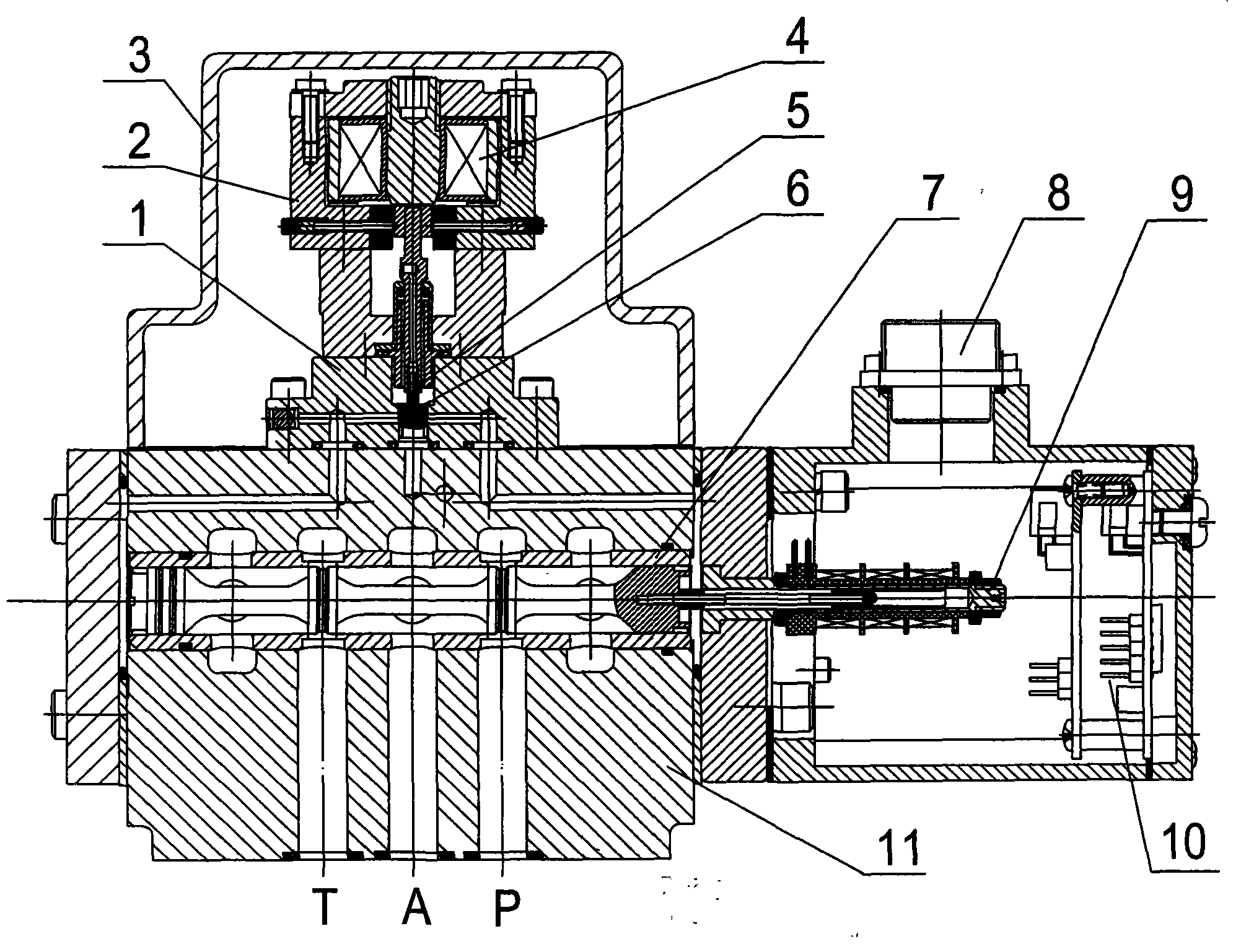

[0016] The special three-way electro-hydraulic servo valve for the rolling mill reduction system provided by the present invention (hereinafter referred to as the three-way electro-hydraulic servo valve) is suitable for the control system of the rolling mill reduction / upper roll gap position, rolling pressure or rolling force with high dynamic response requirements .

[0017] The structure of the three-way electro-hydraulic servo valve is as follows: figure 1 As shown, it is mainly composed of the main valve, jet tube pilot stage and detection feedback device, among which: the main valve is a four-step three-way slide valve with valve sleeve 7, and is driven by the jet tube pilot stage to adapt to the working conditions of the rolling mill. demand and make the main spool have good guidance and not easy to jam; the application of jet tube type pilot stage control makes this three-way servo valve have good pollution resistance; the position control of the main spool (hereinafter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com