High-speed sealing machine, printing/sealing all-in-one machine and control method of printing/sealing all-in-one machine

A technology for stamping machines and printers, applied in printing, typewriters, stamping, etc., can solve problems such as safety needs to be improved, and achieve the effects of high automation, no paper jams, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

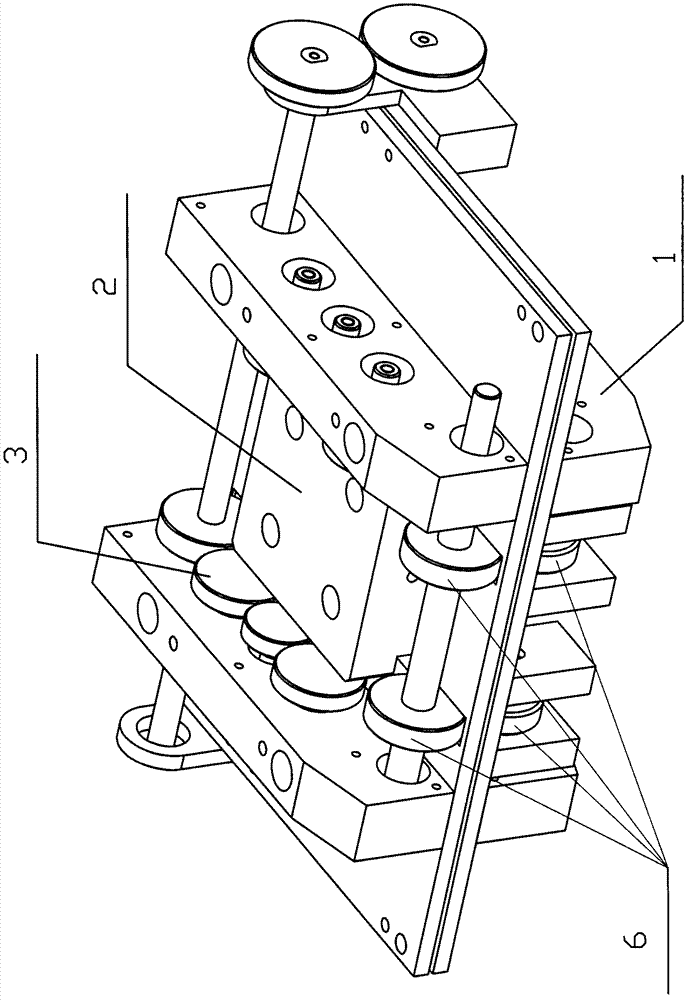

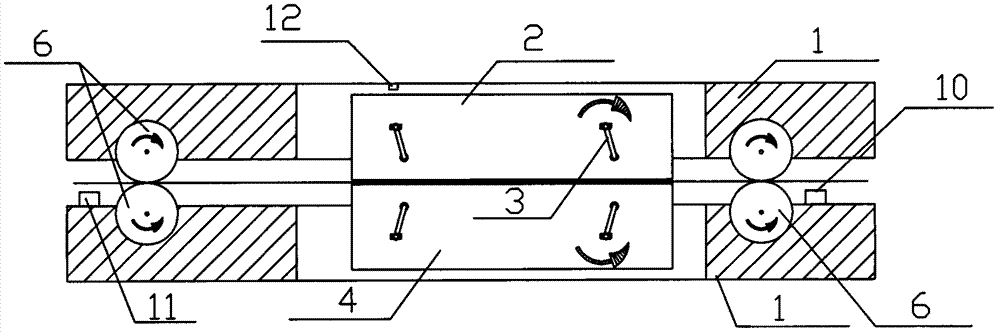

[0028] Implementation mode one: if Figure 1-3 As shown, this high-speed stamping machine includes a stamping mechanism, which comprises a seal, an anvil and a base frame 1, which is provided with a movable platform 2 on the base frame 1, and the movable platform 2 connects with the base frame through a crank 3 1 are connected to form a parallelogram mechanism. This high-speed stamping machine also includes a secondary parallelogram mechanism. The secondary parallelogram mechanism is composed of a base frame 1, a crank 3 and a secondary movable platform 4. And on the auxiliary movable platform 4, the crank 3 of the auxiliary parallelogram mechanism rotates synchronously with the crank 3 of the parallelogram mechanism, but in the opposite direction, all driven by the stamping motor 5. A seal is a seal containing printing ink. A pair of paper pulling wheels 6 are arranged at the paper outlet of the stamping mechanism, and the paper pulling wheels 6 are driven by a paper output ...

Embodiment approach 2

[0032] Embodiment 2: The printing / stamping all-in-one machine of the present invention includes a printer. The paper outlet of the printer is provided with the high-speed stamping machine described in Embodiment 1. The paper outlet of the printer is connected to the paper inlet of the stamping mechanism.

[0033] The control method of the printing / stamp all-in-one machine of the present invention comprises the following steps:

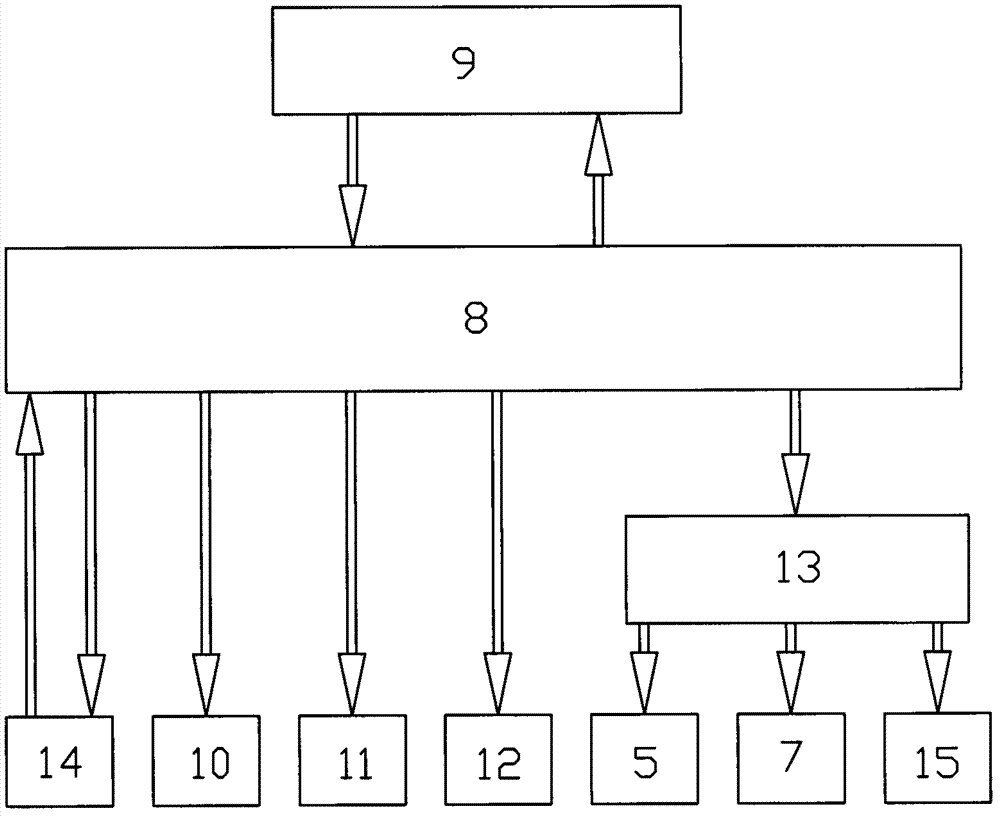

[0034] 1), use a computer or a local area network composed of multiple computers as the background monitoring system of the printing / stamping all-in-one machine, connect the external communication interface 13 of the high-speed stamping machine and the printer to the background monitoring system, and the background monitoring system real-time Read the status parameters of the printer and high-speed stamping machine;

[0035] 2) Before work, the background monitoring system sends printing instructions and stamping instructions to the printer and the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com