Automatic stamping mechanism based on copper stamp

A driving mechanism and copper stamp technology, applied in printing, stamping, etc., can solve the problems of increasing the difficulty and cost of stamp engraving, high failure rate, easy jamming, etc., and achieve the effect of saving stamp engraving cost, low failure rate, and not easy jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

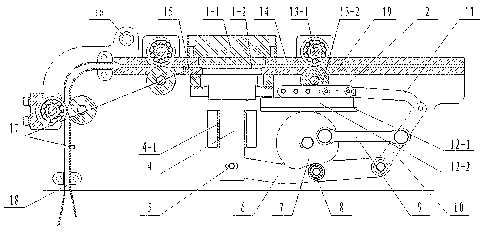

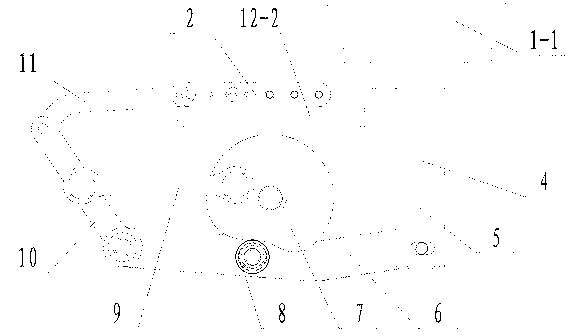

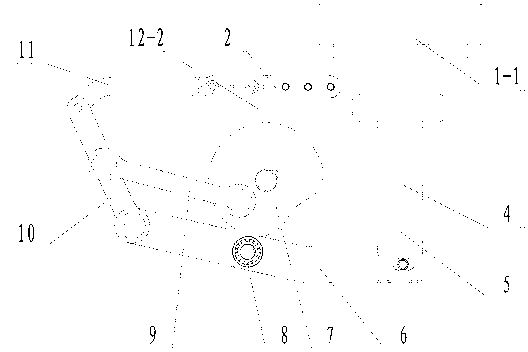

[0018] An automatic stamping mechanism based on a copper stamp, the structure includes a paper feed channel 18 connected to the paper output channel of the printer, a paper output channel 19 connected to the end of the paper feed channel 18, a paper feeding drive mechanism, a stamp mechanism, and control management circuit, the important thing is: the structure of the automatic stamping mechanism also includes an automatic ink replenishment mechanism, and the automatic ink replenishment mechanism and the stamp mechanism form a type of first withdrawing the seal and then applying oil by means of a composite drive mechanism arranged under the paper output channel 19 fit structure. In this way, driven by the composite driving mechanism, the copper stamp in the stamp mechanism can have a degree of freedom of movement in the vertical direction, and at the same time, the automatic ink replenishment mechanism can have a degree of freedom of movement in the horizontal direction. The en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com