Hydraulic bulk feed truck

A transporter, hydraulic technology, applied in the field of hydraulic system-driven unloading devices, can solve problems such as threatening the safety of livestock and poultry in the farm, increasing user expenditure, and feed cost, labor and time, etc., so as to avoid feed pollution, simplify links, The effect of reducing the number of shipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

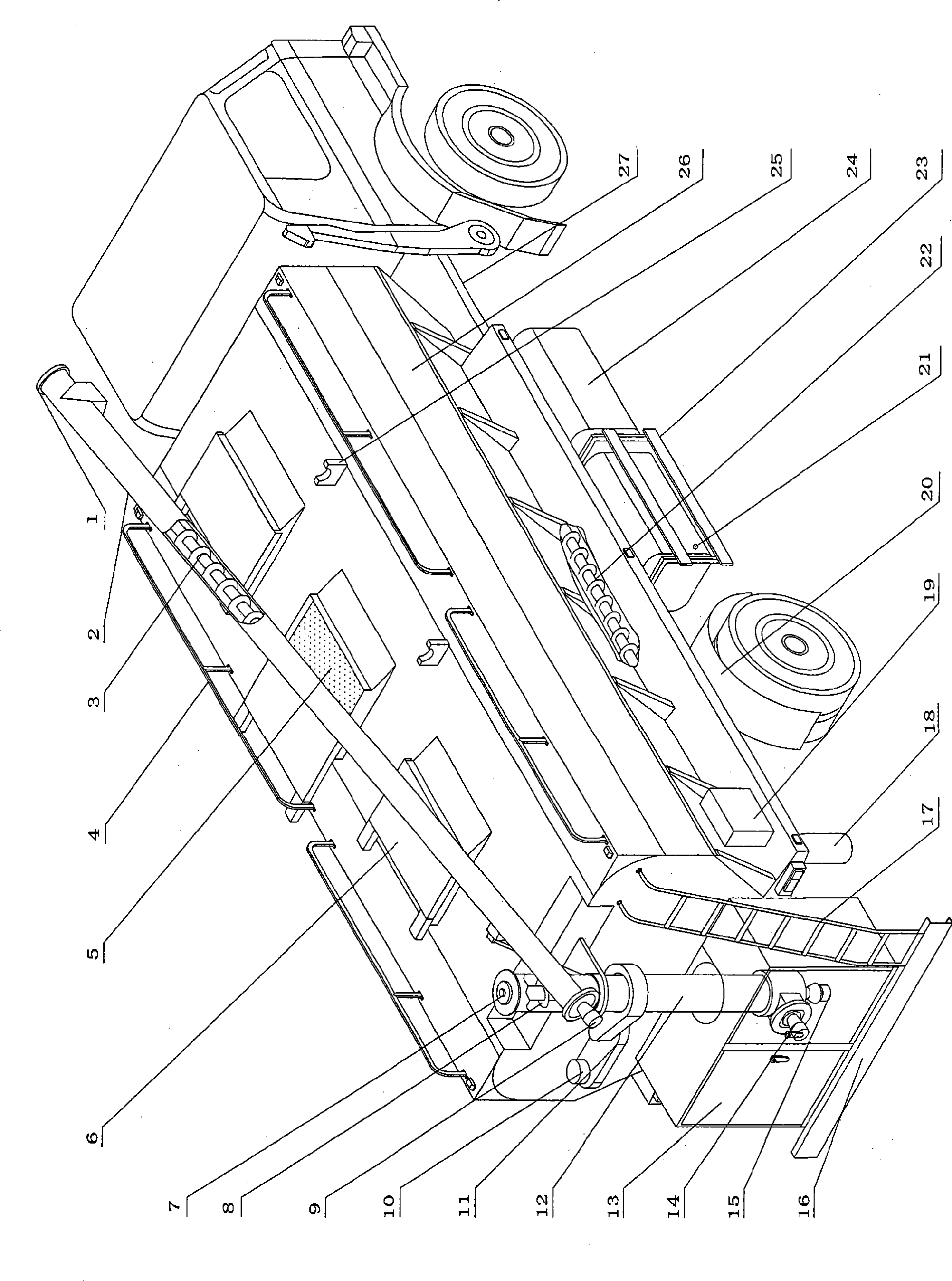

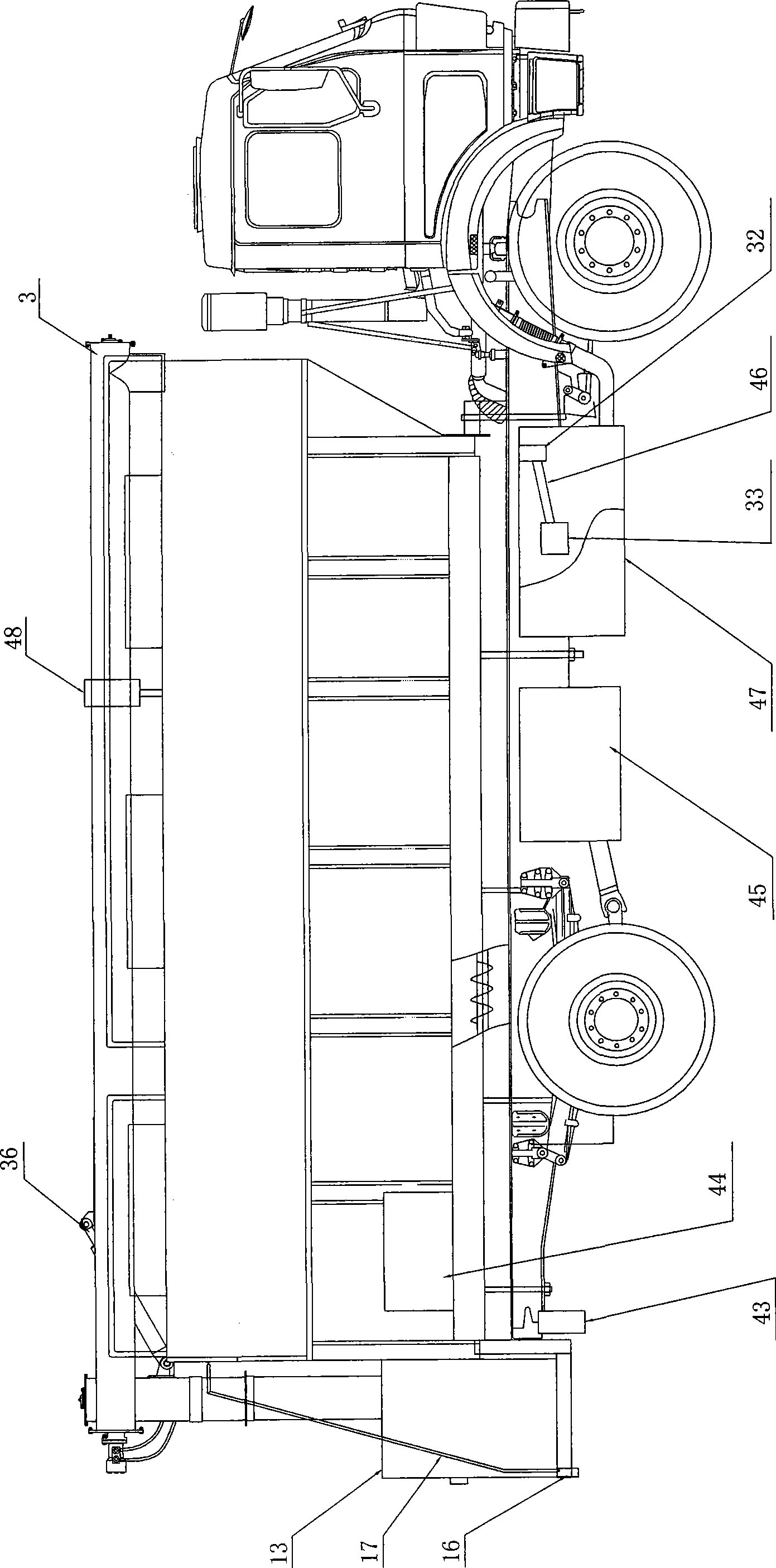

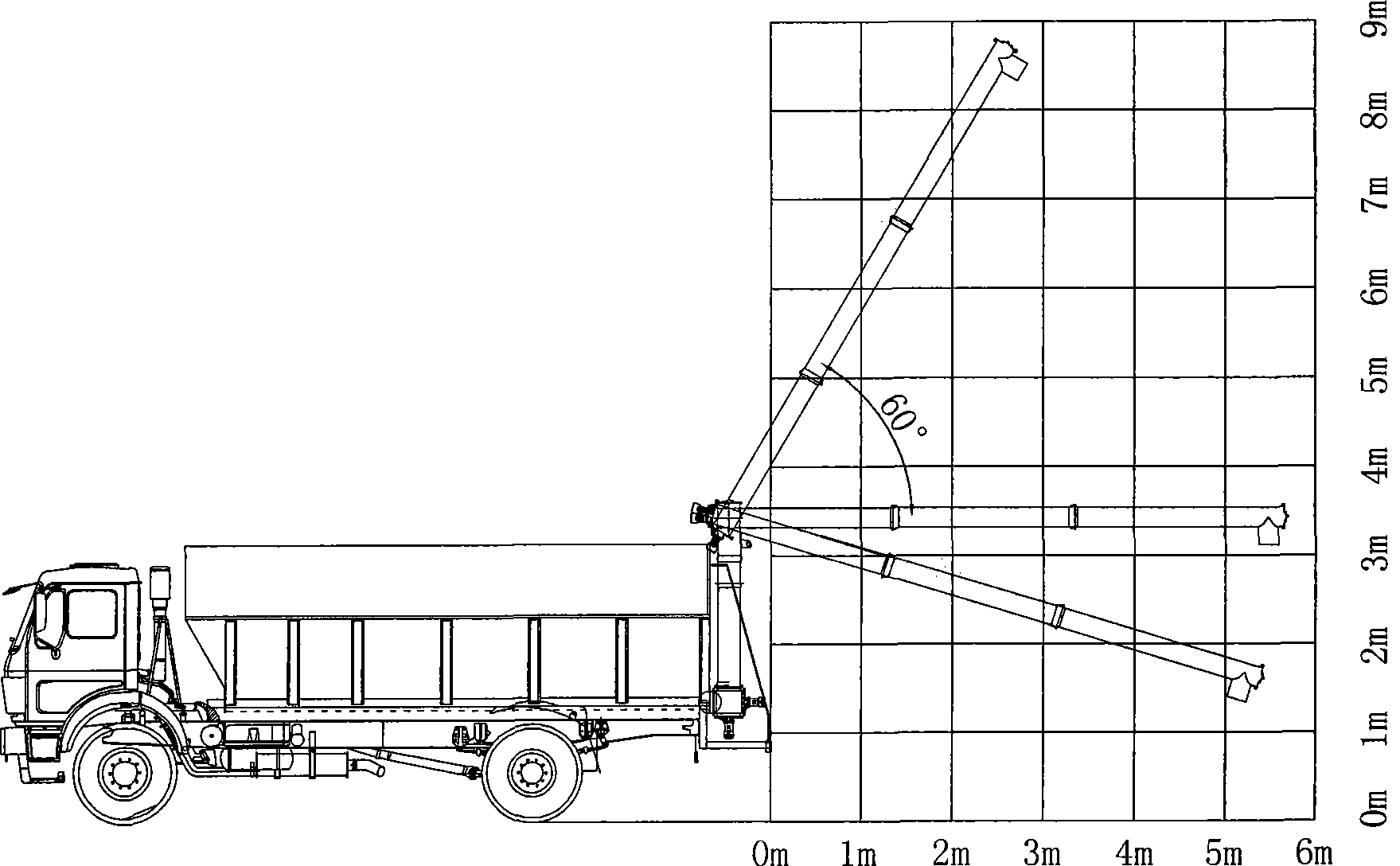

[0046] figure 1 , Picture 1-1 Shown, the present invention comprises automobile transmission, is arranged on the tank body 26 on automobile body, and unloading device, and the power take-off gear of power take-off 32 meshes with the power gear of described automobile transmission through clutch, and power take-off passes through The transmission shaft 46 is connected with the high-pressure oil pump 33; it also has a hydraulic system: the high-pressure oil pump 33 is connected with the triple distribution valve 34 through pipelines, and the three output ends of the triple distribution valve are respectively connected with the angle hydraulic motor 10, the lifting cylinder 36 and the horizontal cylinder connected in series. Unloading, vertical unloading, and movable unloading hydraulic motors 14, 15, 9; the unloading device is composed of a horizontal unloading system 22, a vertical unloading system 8 and an active unloading system 3, and the three are respectively composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com