Material distribution device

A material distribution device and material distribution mechanism technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of complex debugging, poor stability, inconvenient maintenance, etc., to achieve easy maintenance, simple structure, and not easy to jam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

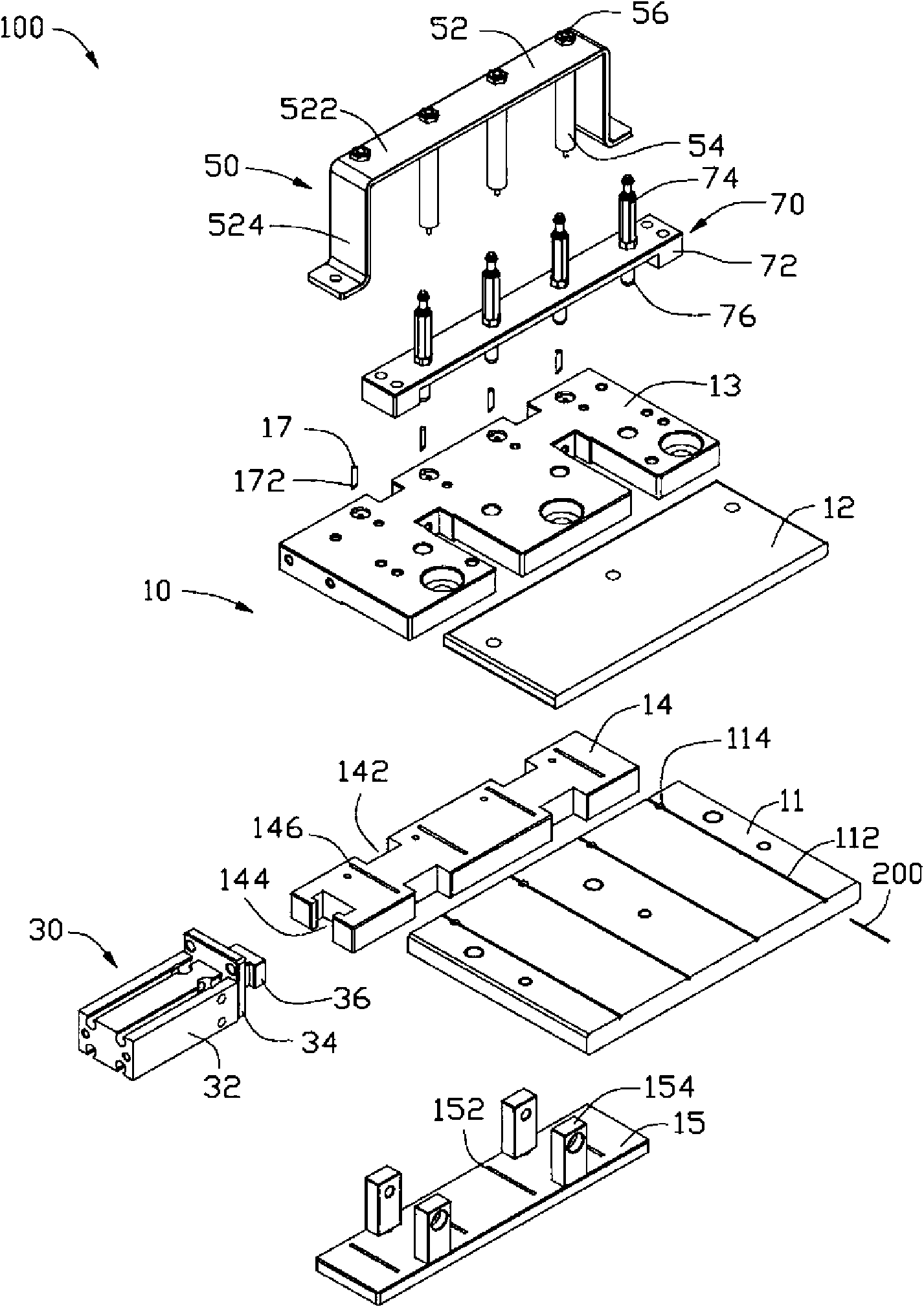

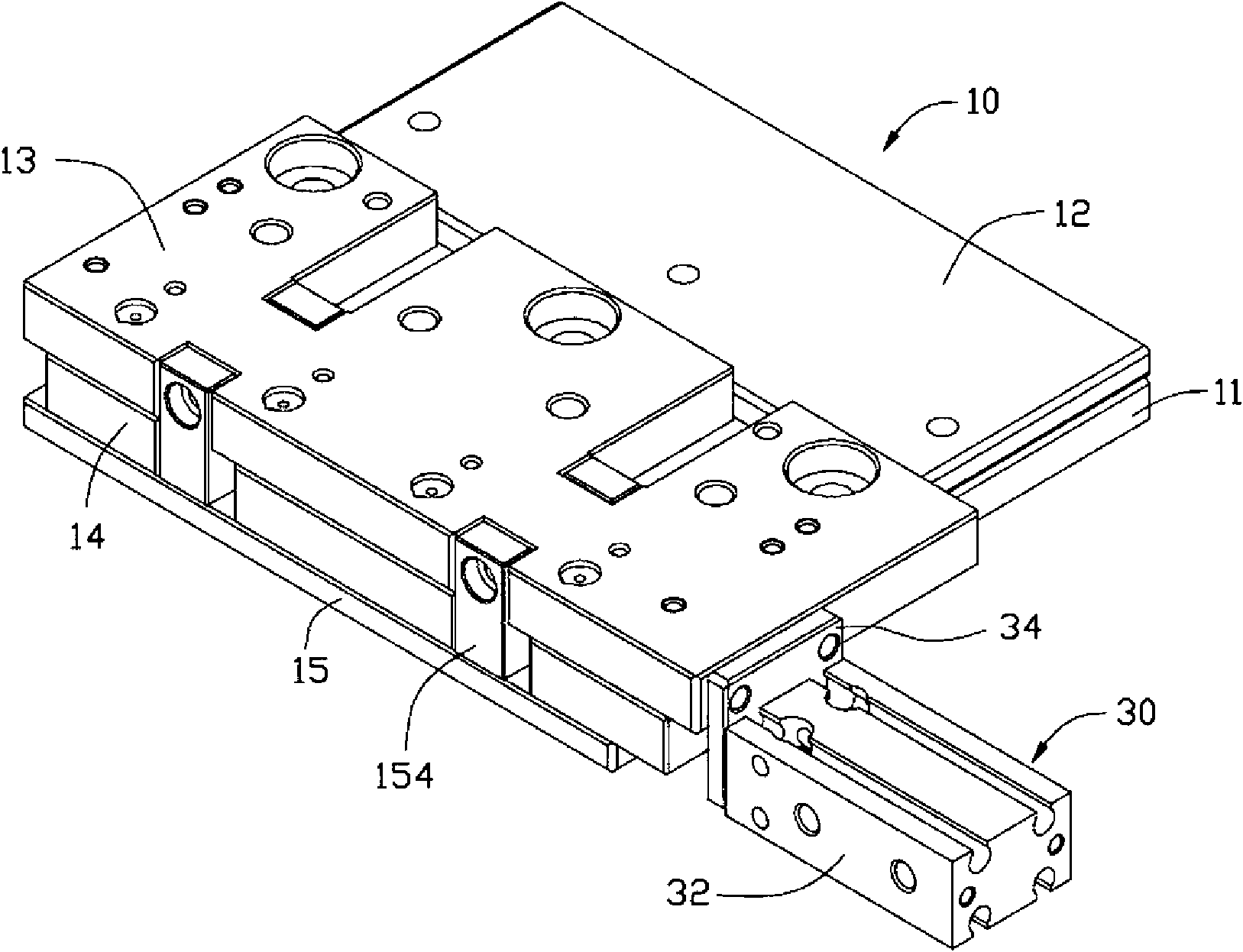

[0017] see figure 1 , the material distributing device 100 of the preferred embodiment of the present invention is used for distributing and conveying the elongated cylindrical or needle-shaped workpiece 200 . The material distribution device 100 includes a material distribution mechanism 10 , a sliding mechanism 30 , a detection mechanism 50 and a material blocking mechanism 70 .

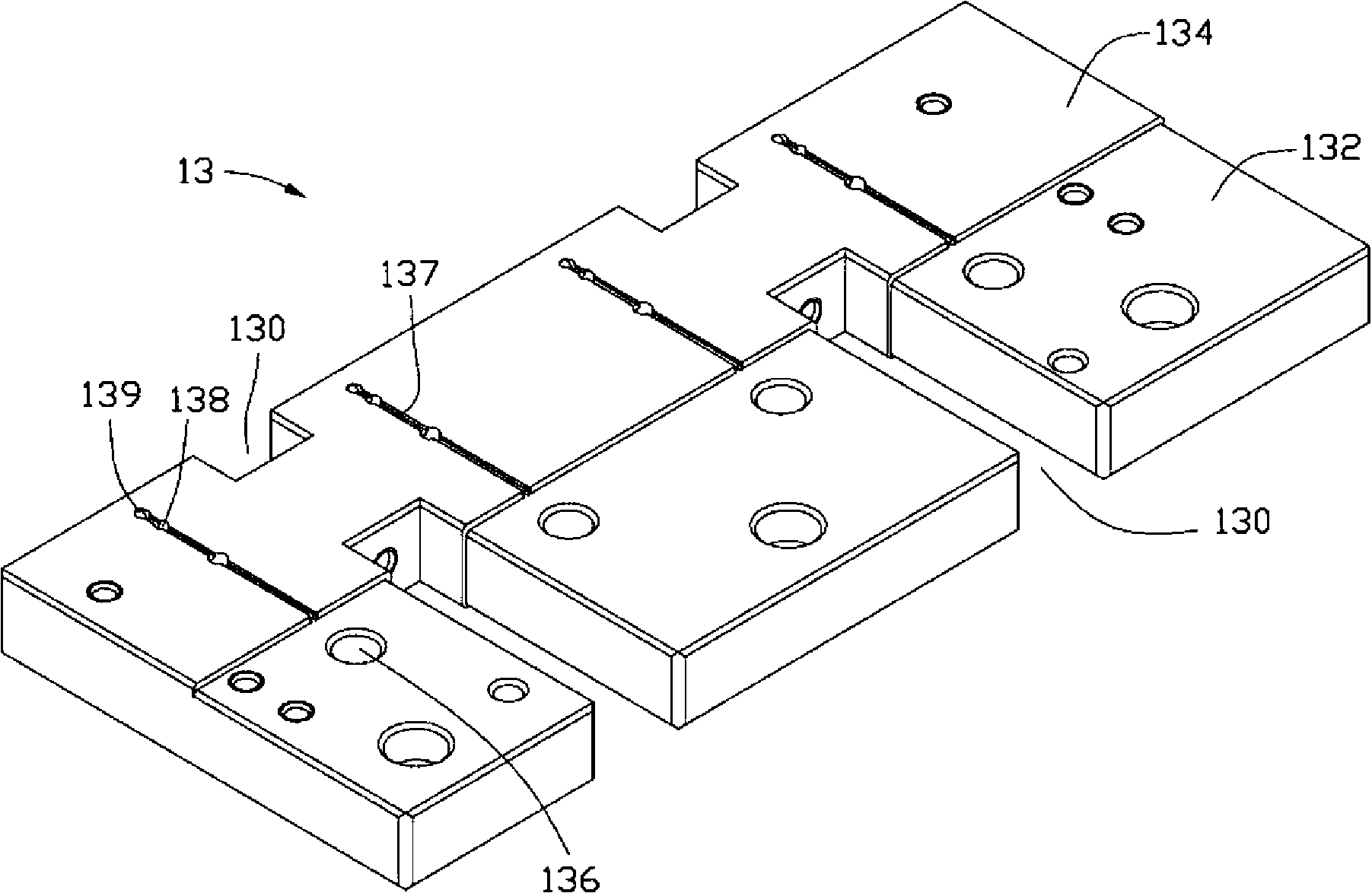

[0018] The distributing mechanism 10 is used for separating workpieces 200 , and includes a feeding plate 11 , a cover plate 12 , a connecting plate 13 , a sliding plate 14 , a guiding plate 15 and a pin 17 .

[0019] A plurality of feeding grooves 112 are provided on the feeding plate 11 , and the size of the feeding grooves 112 is equivalent to that of the workpiece 200 to be distributed. The feeding plate 11 defines a circular groove 114 near one end of each feeding groove 112 . The feeding plate 11 can drive the workpiece 200 to move toward the circular groove 114 under the vibration of a vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com