Laser method and device for boring dense micropore on leather

A laser drilling and leather technology, applied in leather punching/punching/cutting, laser welding equipment, small raw leather/big raw leather/leather/fur treatment, etc., can solve the problem that the distance between the focusing heads should not be too small, energy loss, The system is huge and other problems, to achieve the effect of increasing speed, reliable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

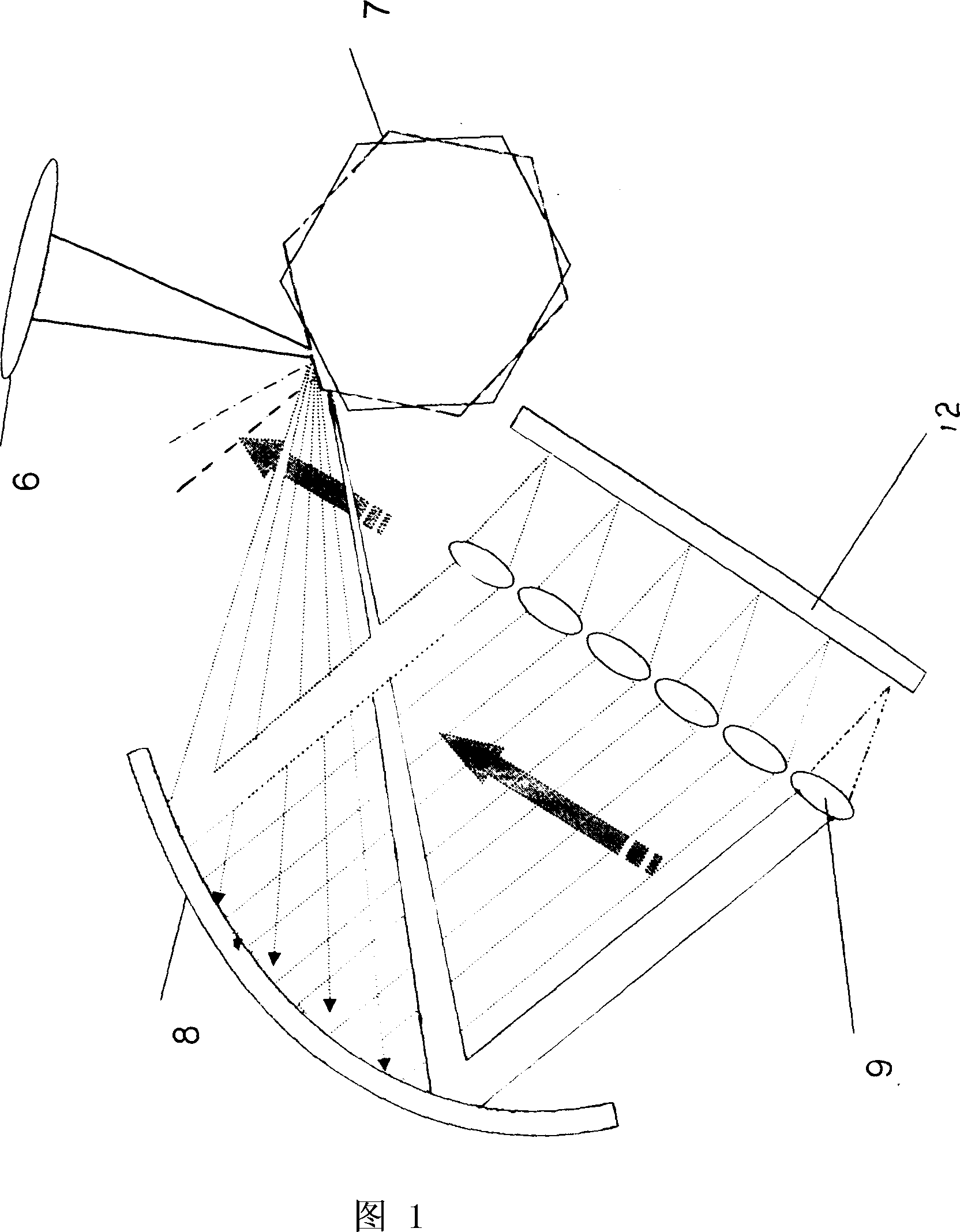

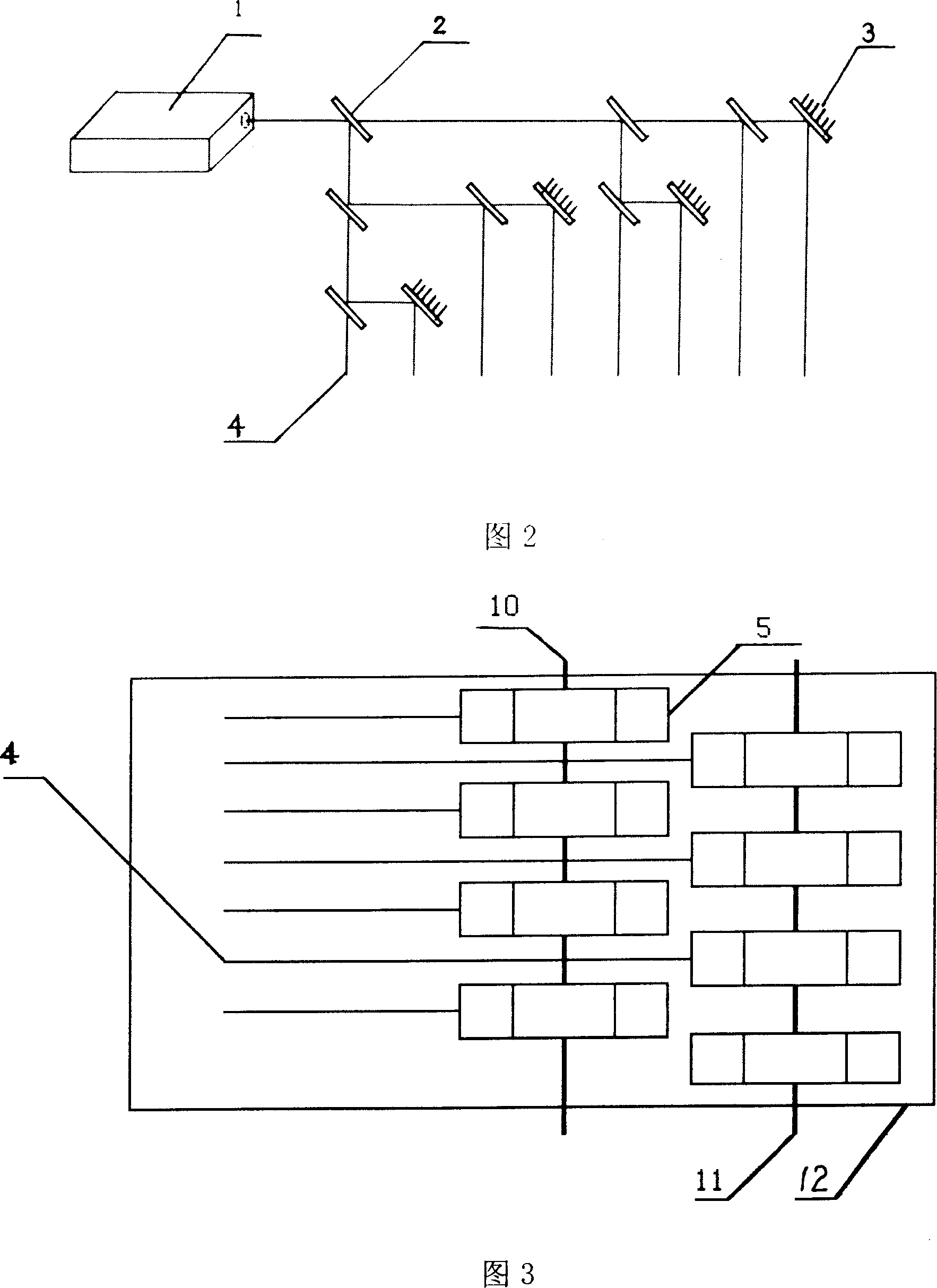

[0014] The laser online drilling method for leather materials provided by the present invention is a high-power continuous laser + optical splitting + integrated rotating prism intensive splitting and focusing processing head to realize multiple simultaneous drilling, specifically: a continuous high-power laser output by a high-power continuous laser After optical splitting, it is divided into 4-16 low-power continuous laser beams, and each low-power continuous laser beam passes through a rotating polygonal mirror, a reflector (or transmission mirror) and multiple (10-40) The integrated focusing processing head composed of focusing mirrors is divided into multiple pulsed laser beams with densely focused lattices to realize simultaneous drilling of multiple rows in the longitudinal direction, that is, multiple integrated focusing heads are respectively vaporized locally on the continuously moving wide-format leather coating machine. Air holes are punched online at the same time....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com