Molding system for sponge pipe

A sponge and control system technology, applied in metal processing and other directions, can solve the problems of inconsistent inner hole diameter, poor tensile performance, inability to punch long sponges, etc., and achieve the effect of fast punching speed and low sponge loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only part of the embodiments of the present invention, and other embodiments obtained by those skilled in the art without creative efforts all belong to the protection scope of the present invention.

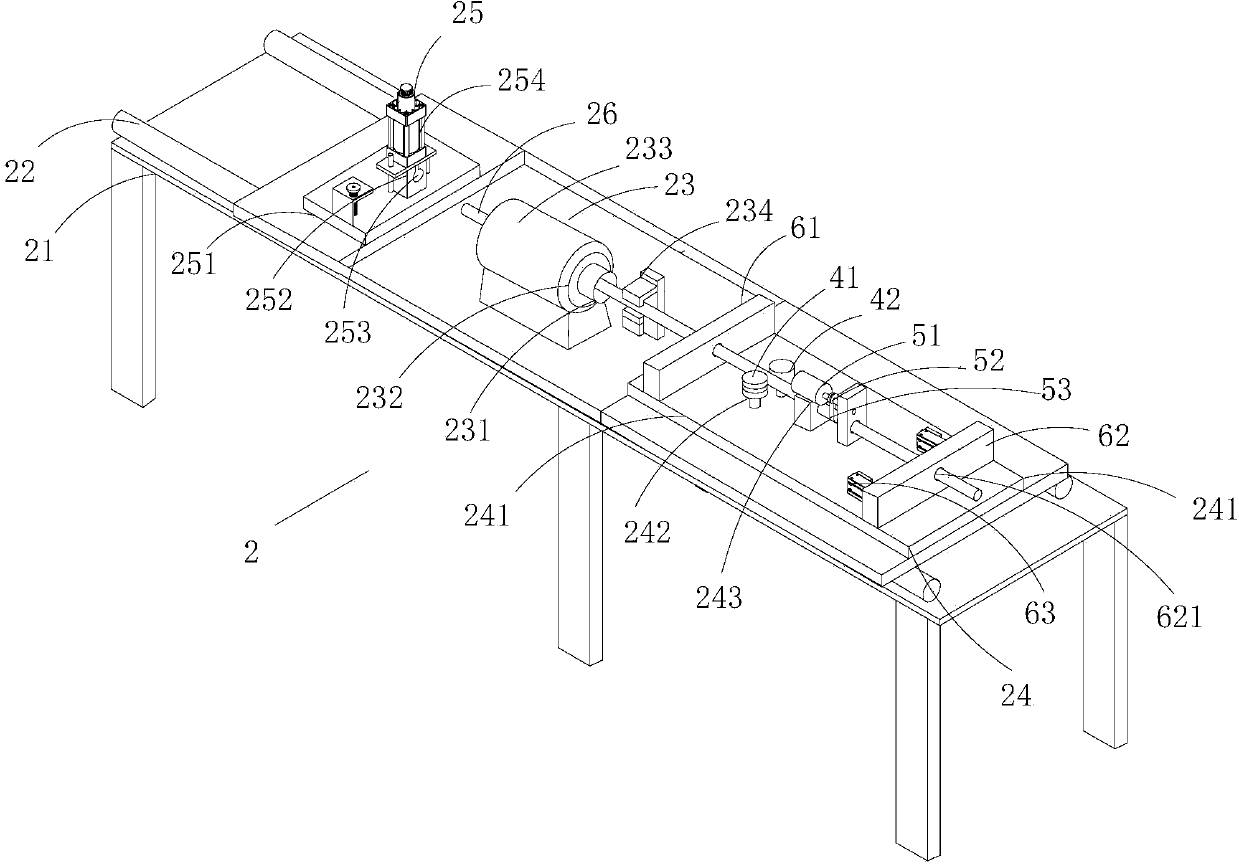

[0020] A forming system for a sponge tube, comprising a punching system 1, a peeling system 2 and a control system, wherein,

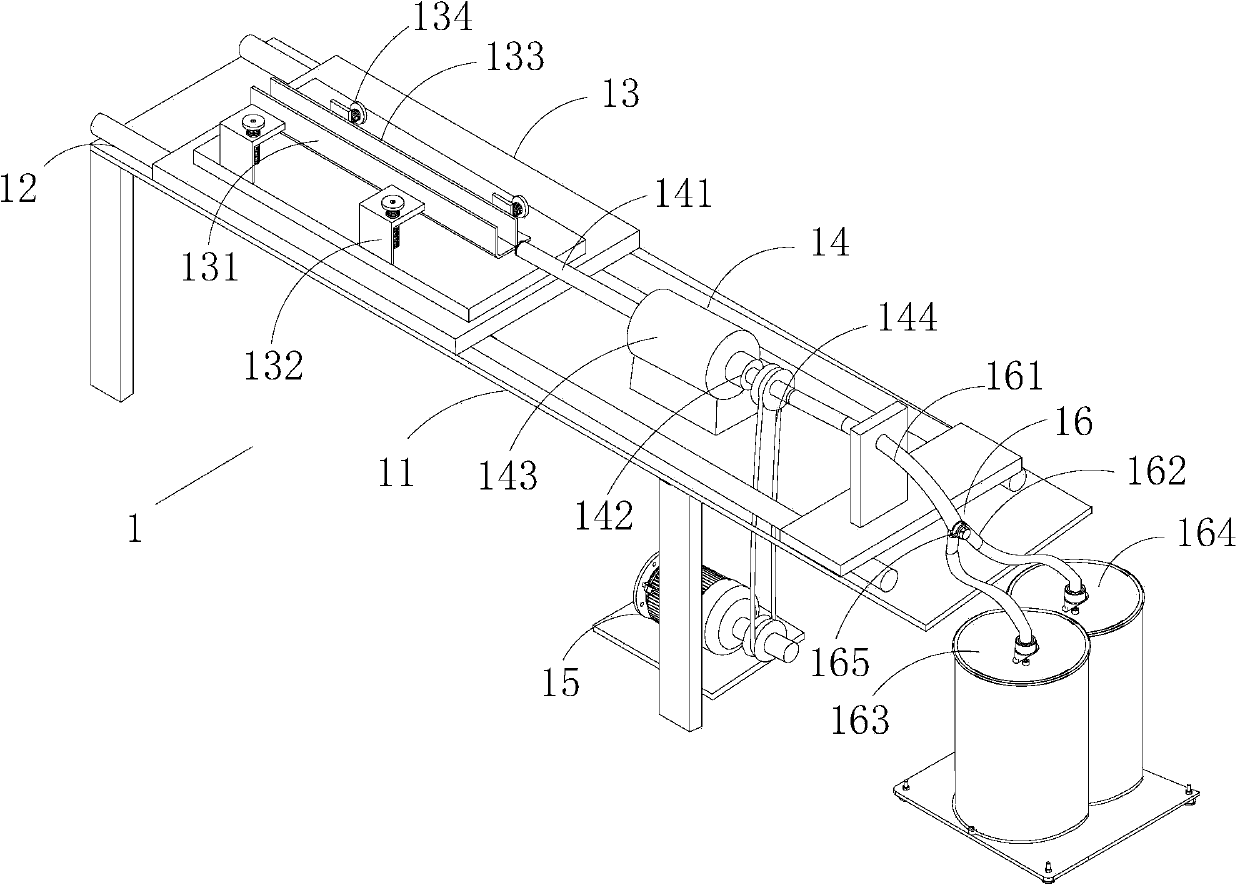

[0021] The punching system 1 comprises a punching system bracket 11, a guide rail 12 installed on the punching system bracket, a fixed seat assembly 13 movable along the guide rail 12, a hollow perforating drill assembly 14 arranged opposite to the fixed seat assembly 13, driving The motor 15 of the hollow perforating drill assembly 14, the sponge wool is placed on the fixed seat assembly 13, and the hollow perforated drill assembly 14 drills the sponge wool; its fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com