Leather perforating equipment for producing leather shoes

A punching equipment, leather technology, applied in raw hide/leather/fur manufacturing equipment, leather punching/punching/cutting, small raw hide/large raw hide/leather/fur processing, etc. Leather, slow punching speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

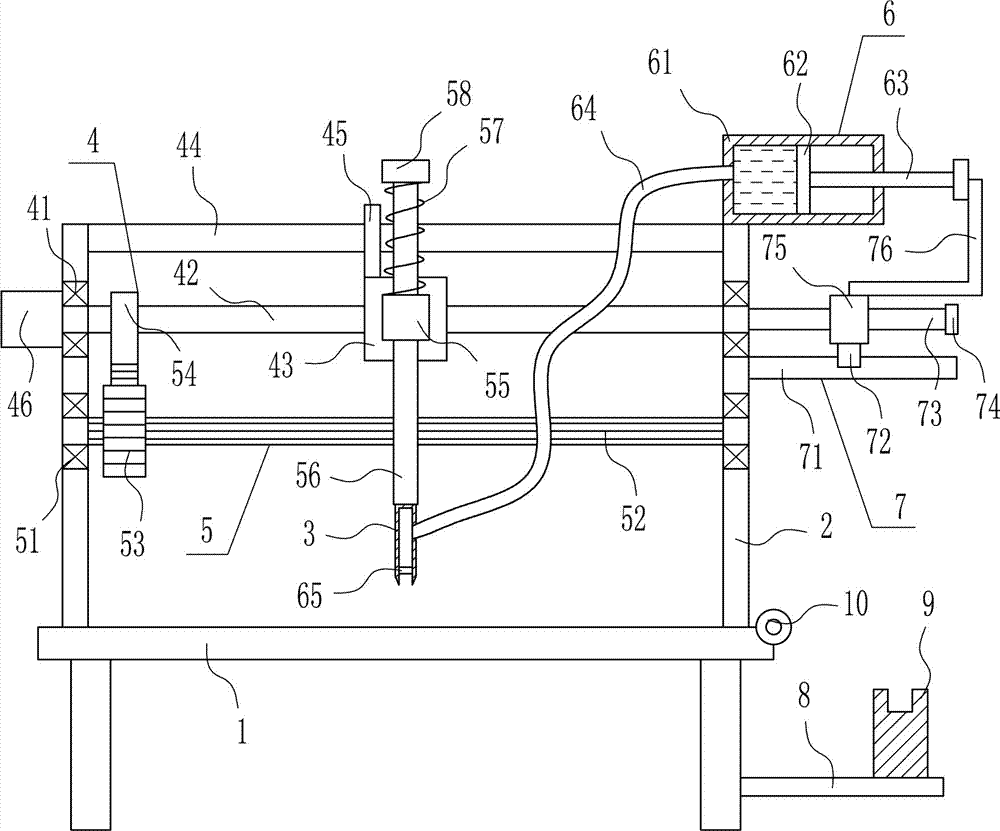

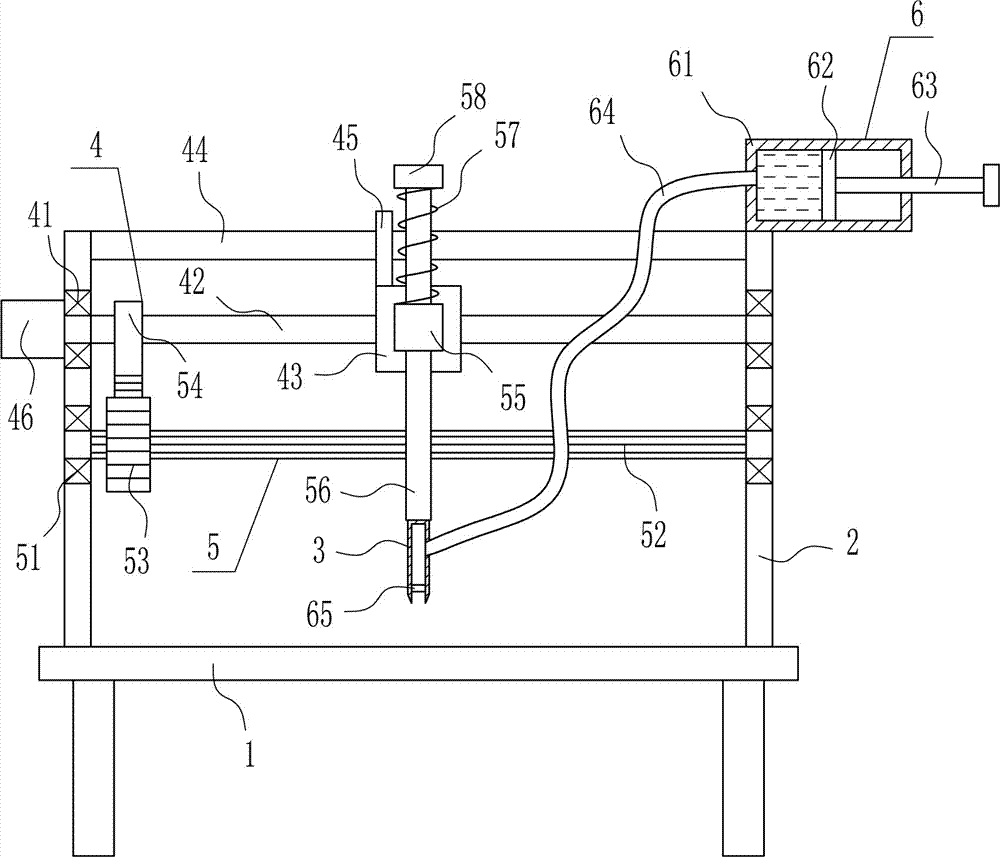

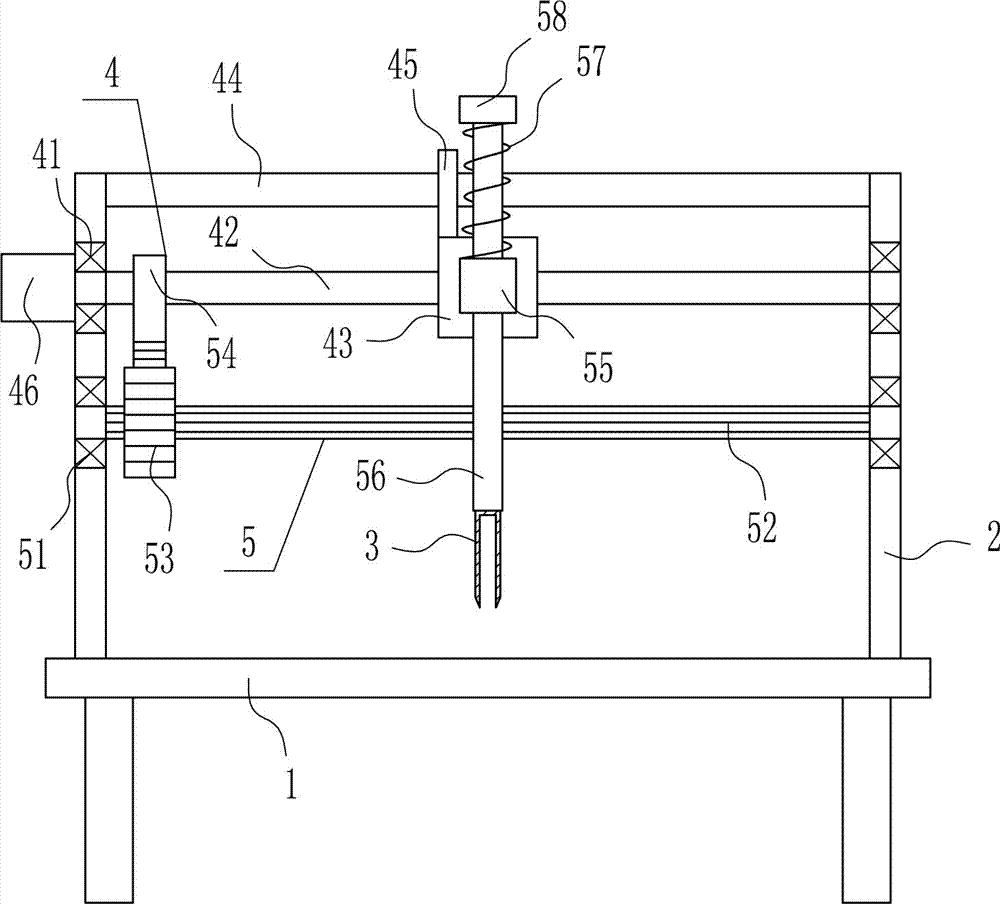

[0031] A kind of leather punching equipment for leather shoes production, such as Figure 1-5 As shown, it includes an operating table 1, a vertical board 2, a punching head 3, a moving device 4 and a lifting device 5. The vertical boards 2 are symmetrically installed on the left and right sides of the top of the operating table 1, and the upper parts of the vertical boards 2 on the left and right sides are There is a moving device 4 between them, and a lifting device 5 is arranged between the middle parts of the vertical plates 2 on the left and right sides. above console 1.

Embodiment 2

[0033] A kind of leather punching equipment for leather shoes production, such as Figure 1-5 As shown, it includes an operating table 1, a vertical board 2, a punching head 3, a moving device 4 and a lifting device 5. The vertical boards 2 are symmetrically installed on the left and right sides of the top of the operating table 1, and the upper parts of the vertical boards 2 on the left and right sides are There is a moving device 4 between them, and a lifting device 5 is arranged between the middle parts of the vertical plates 2 on the left and right sides. above console 1.

[0034] The moving device 4 includes a first bearing seat 41, a first screw mandrel 42, a first nut 43, a cross bar 44, a first sliding sleeve 45, and a motor 46, and the upper parts of the left and right vertical plates 2 are embedded with the first The bearing seat 41 and the first bearing seat 41 are arranged symmetrically. The first screw mandrel 42 is connected between the first bearing seats 41 on...

Embodiment 3

[0036] A kind of leather punching equipment for leather shoes production, such as Figure 1-5 As shown, it includes an operating table 1, a vertical board 2, a punching head 3, a moving device 4 and a lifting device 5. The vertical boards 2 are symmetrically installed on the left and right sides of the top of the operating table 1, and the upper parts of the vertical boards 2 on the left and right sides are There is a moving device 4 between them, and a lifting device 5 is arranged between the middle parts of the vertical plates 2 on the left and right sides. above console 1.

[0037] The moving device 4 includes a first bearing seat 41, a first screw mandrel 42, a first nut 43, a cross bar 44, a first sliding sleeve 45, and a motor 46, and the upper parts of the left and right vertical plates 2 are embedded with the first The bearing seat 41 and the first bearing seat 41 are arranged symmetrically. The first screw mandrel 42 is connected between the first bearing seats 41 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com