Packing bag punching equipment

A technology of punching equipment and packaging bags, which is applied in packaging and other directions, can solve the problems of slow punching speed, slow moving speed of punching needles, burrs, etc., and achieve the effects of convenient control, improved punching work efficiency, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

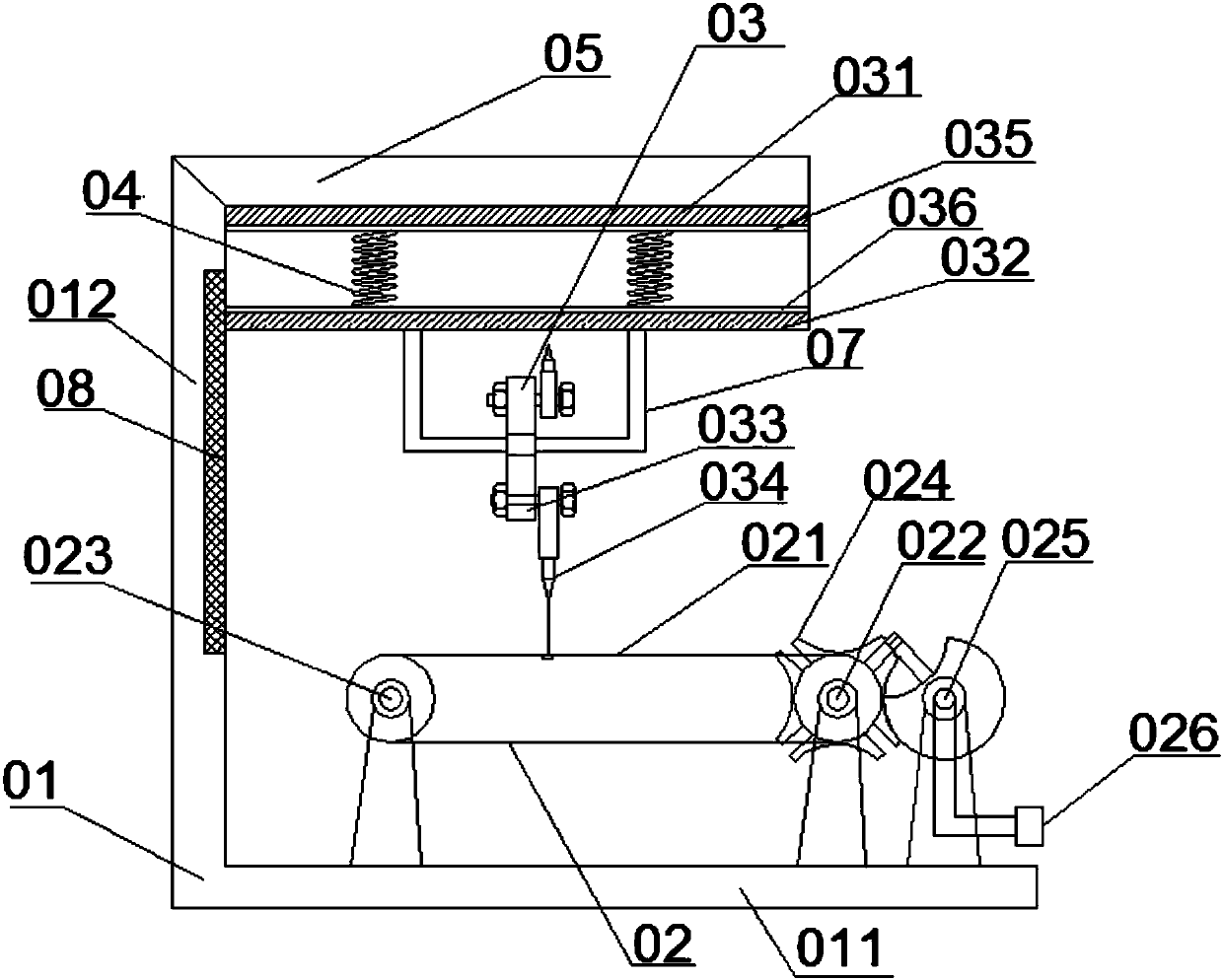

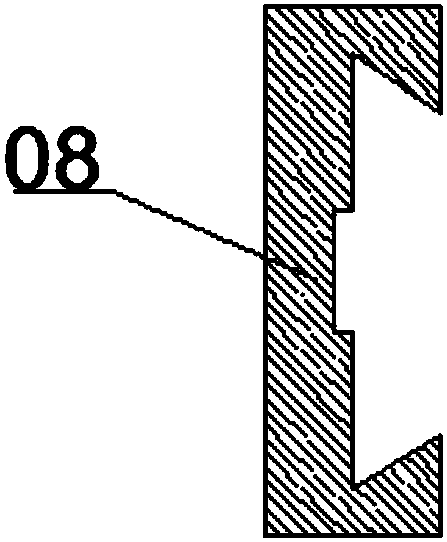

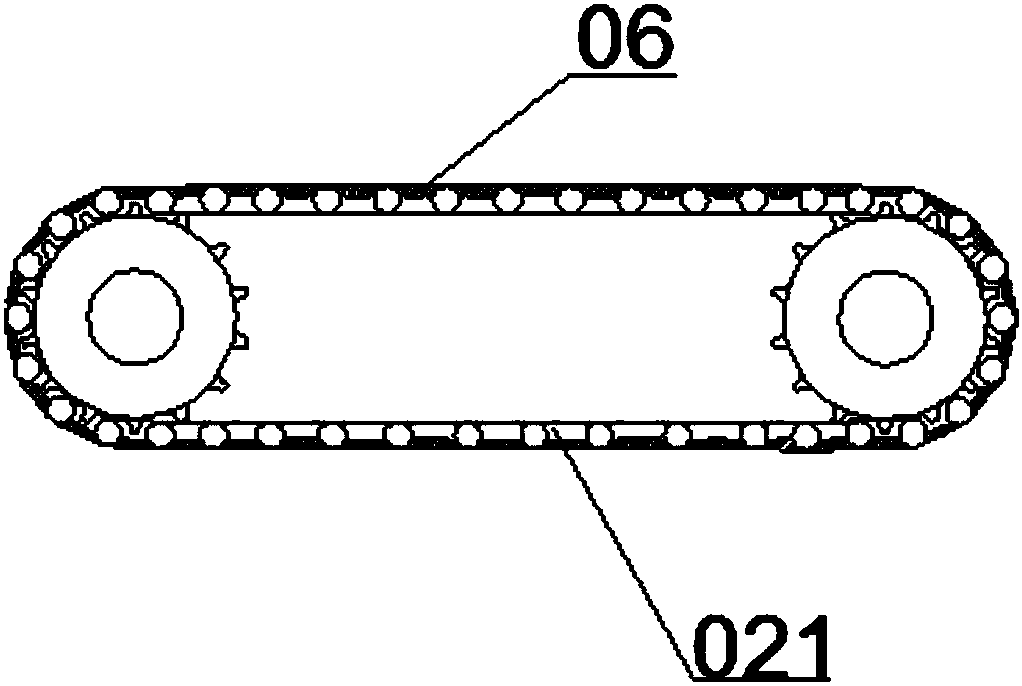

[0029] Such as figure 1As shown, a packaging bag punching equipment includes a base 01, a transmission mechanism 02, a punching mechanism 03, and a support base 05 fixedly connected to the top of the base 01. The base 01 is L-shaped and includes a horizontal part 011 and a vertical part 012. , the transmission mechanism 02 is fixed on the horizontal part 011 of the base 01, the support seat 05 is welded to the top of the vertical part 012 of the base 01, and the punching mechanism 03 is arranged on the support seat 05 facing the transmission mechanism 02; specifically, punching Mechanism 03 includes an upper fixed block 031, a lower moving block 032, a circular dial 033 and a perforated needle 034 arranged on the circular needle disk 033, the number of perforated needles 034 is four, and four described perforated needles 034 adopt annular Array distribution, the circular array of tines 034 is distributed from the four directions of the disc, and every two tines 034 are set at ...

Embodiment 2

[0037] Such as Figure 4 As shown, Embodiment 2 is basically the same as Embodiment 1, except that the number of elastic members 04 arranged between the upper fixed block 031 and the lower moving block 032 is three, and the bottom of the lower moving block 032 is slidably connected. There are 2 groups of brackets 07, and the 2 groups of brackets 07 are respectively connected with an annular dial 033 by bolts. Since the punching needle 034 on the annular dial 033 can be adjusted and used according to needs, the packaging bag can pass through the conveyor belt 021 at one time. Holes with different apertures are punched in different parts, which doubles the efficiency of punching bags, meets production needs, and is suitable for popularization and application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com