Horizontal-vertical type six-axis disc machine tool for pipe punching

A disc and pipe technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of low efficiency, inability to drill continuously, slow processing speed, etc., and achieve high precision performance, speed up the drilling speed, and improve the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

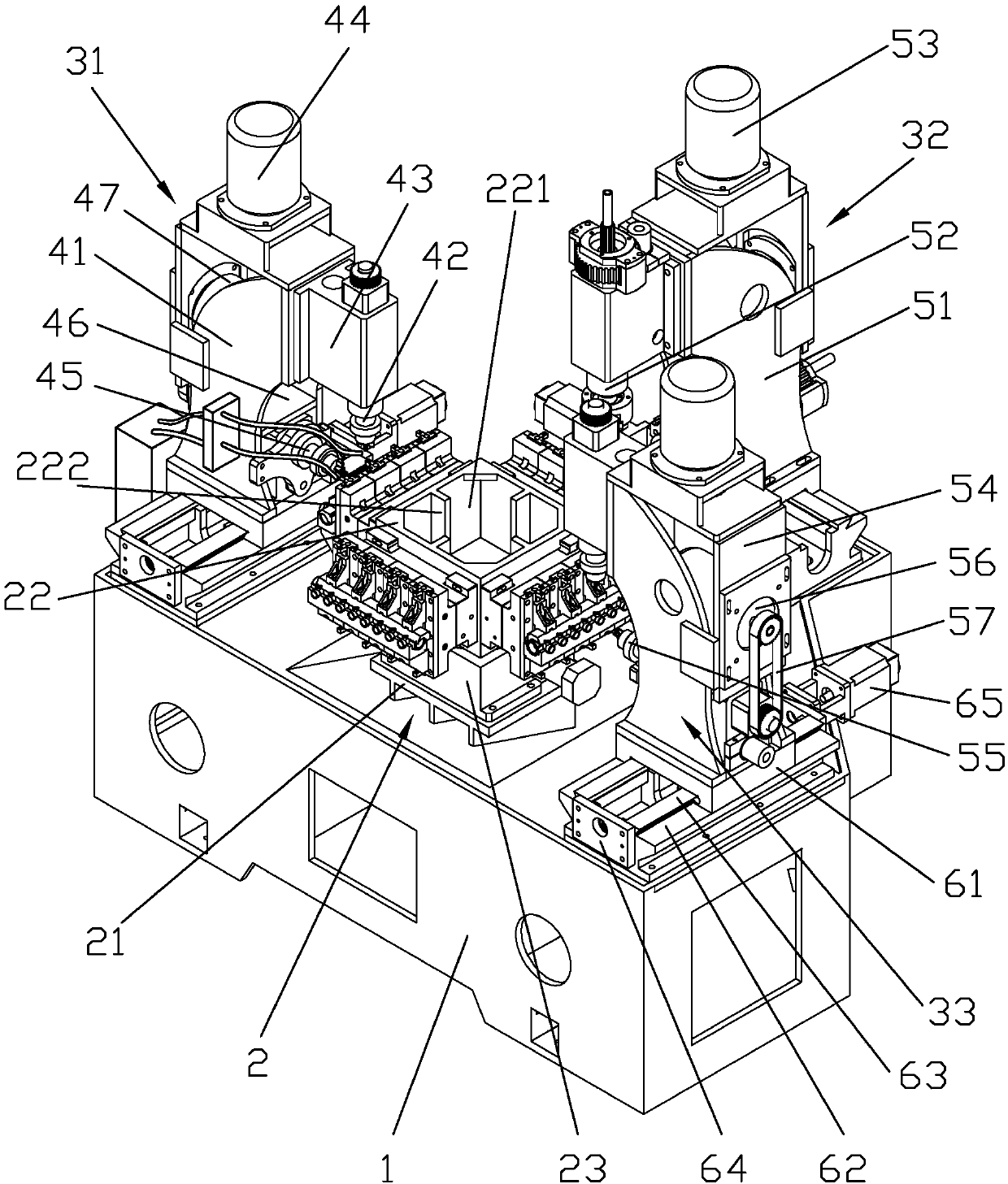

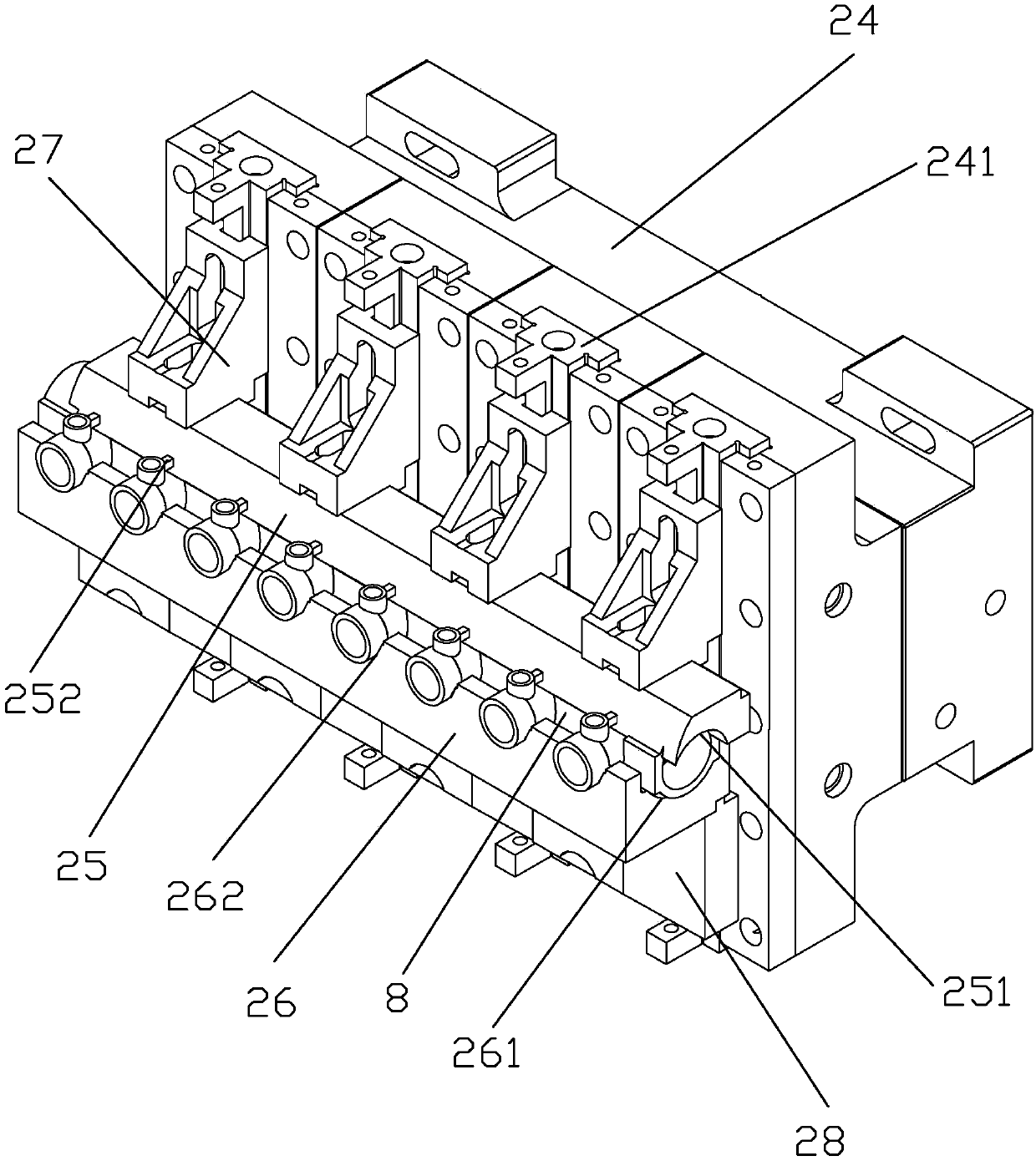

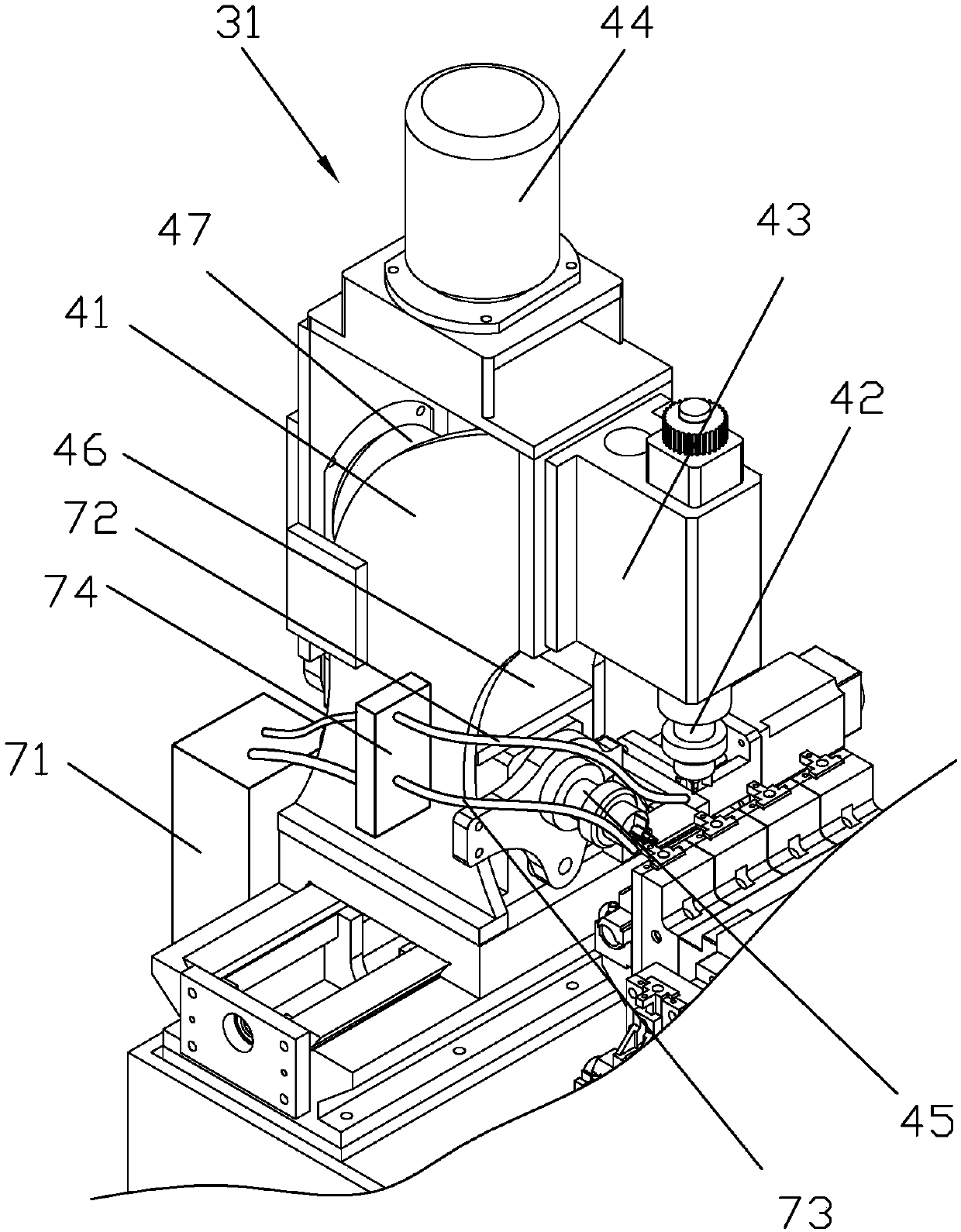

[0024] like figure 1 , figure 2 and Figure 4The shown horizontal and vertical six-axis disc machine tool for pipe drilling includes a machine base 1 and a base plate 11 arranged on the top surface of the base plate. A disc base 21 is provided in the center of the top surface of the base plate 11. A square box 22 is arranged on it, and the square box 22 is connected with the disc base 21 in rotation. An indexing plate 23 is arranged between the square box 22 and the disc base 21. The side of the disc base 21 is provided with Indexing motor; the top surface of the square box 22 is provided with a cavity 221, and the inner side of the cavity 221 is provided with reinforcing ribs 222. The cavity 221 is set on the square box 22, which not only reduces the weight of the square box 22, reduces the working pressure of the index plate 23, prolongs the service life of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com