F-theta lens unit

A lens and lens technology, applied in the optical field, can solve the problem that F-Theta cannot meet the drilling requirements, and achieve the effect of uniform size, no tool loss and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

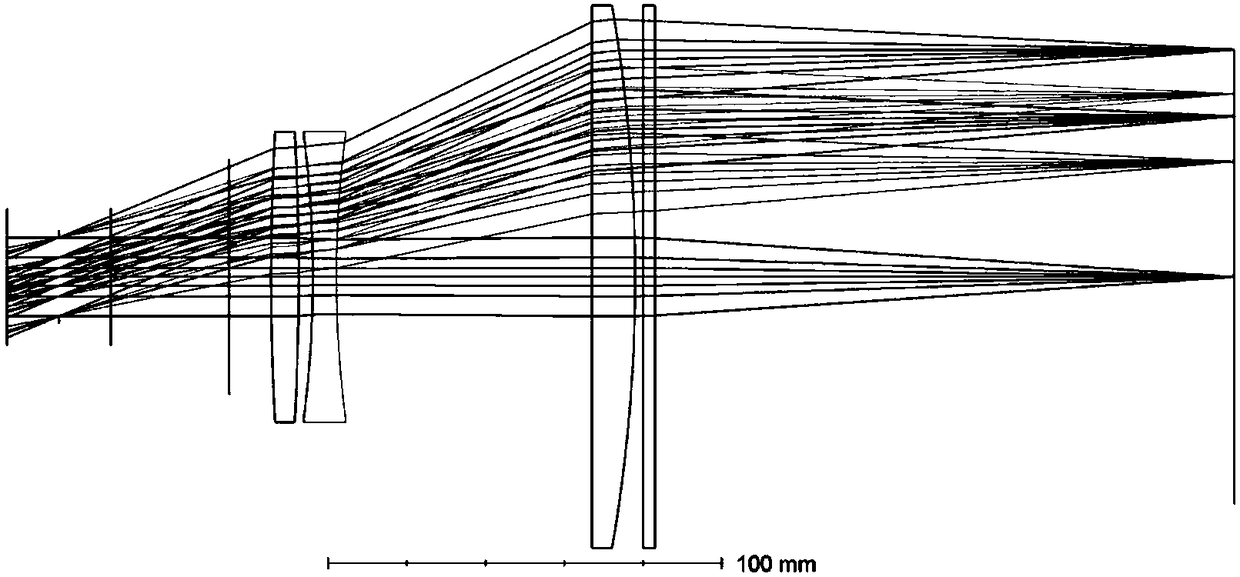

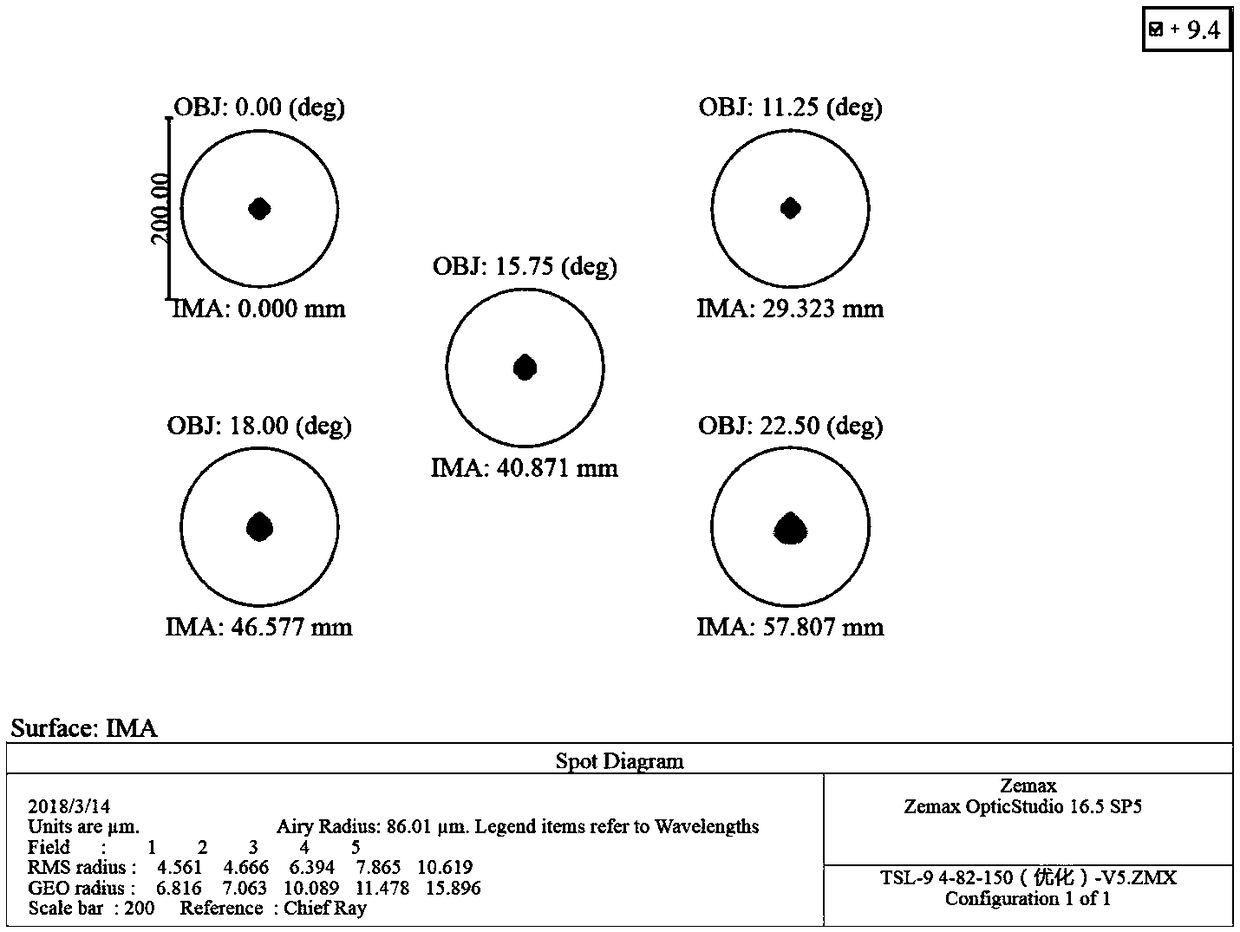

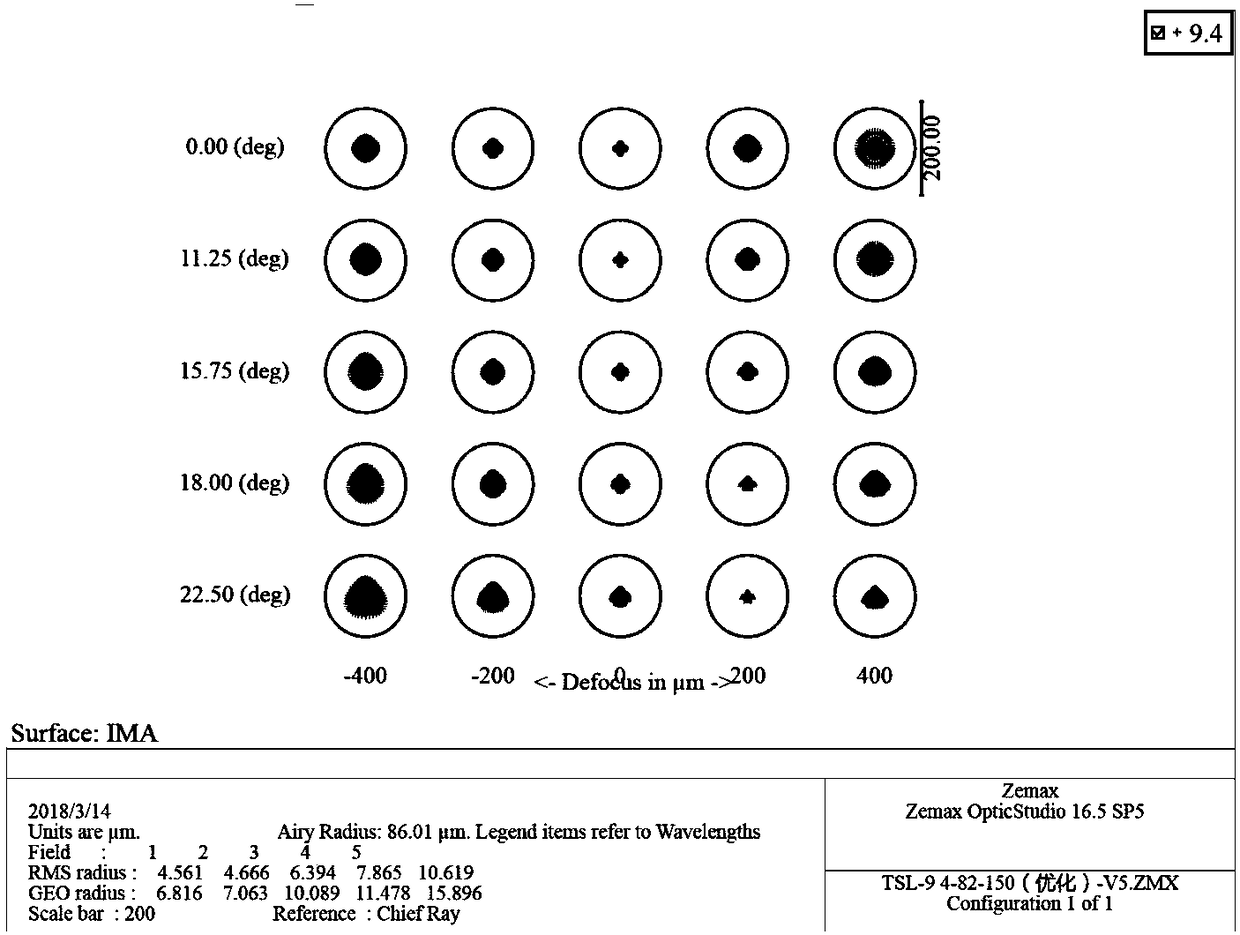

[0033] like Figure 8 Shown: an F-Theta lens, including a first lens, a second lens, a third lens and a window set in sequence along the light incident direction, the first lens is a positive lens, the second lens is a negative lens, and the third lens is a positive lens; Figure 8 Among them, the realization part parallel to the first lens, the second lens, the third lens and the window plate is the stepped outline of the inner surface of the mirror holder except for various pressure rings, gaskets and transition rings;

[0034] The first lens includes opposite first and second curved surfaces, the radius of curvature of the first curved surface is 680 mm, the radius of curvature of the second curved surface is 680 mm, and the central thickness of the first lens is 7 mm; the second lens includes an opposite third curved surface and the fourth curved surface, the radius of curvature of the third curved surface is -282mm, the radius of curvature of the second curved surface is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com