Perforating device of lead acid storage battery shell

A technology of lead-acid battery and punching device, which is applied in metal processing and other directions, can solve problems such as difficult to guarantee consistency, increase production cost, and process complexity, and achieve the effects of fast punching speed, high work efficiency, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

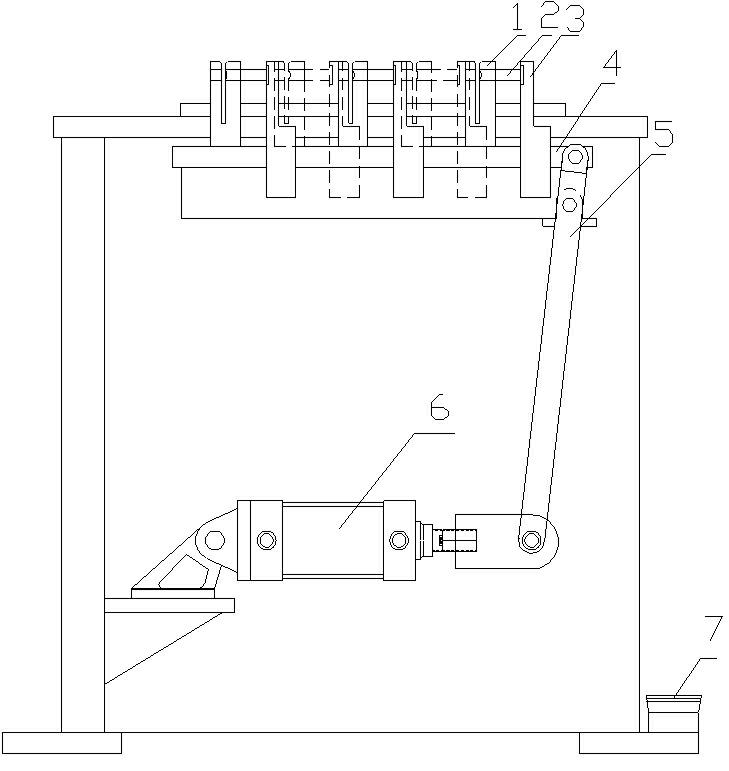

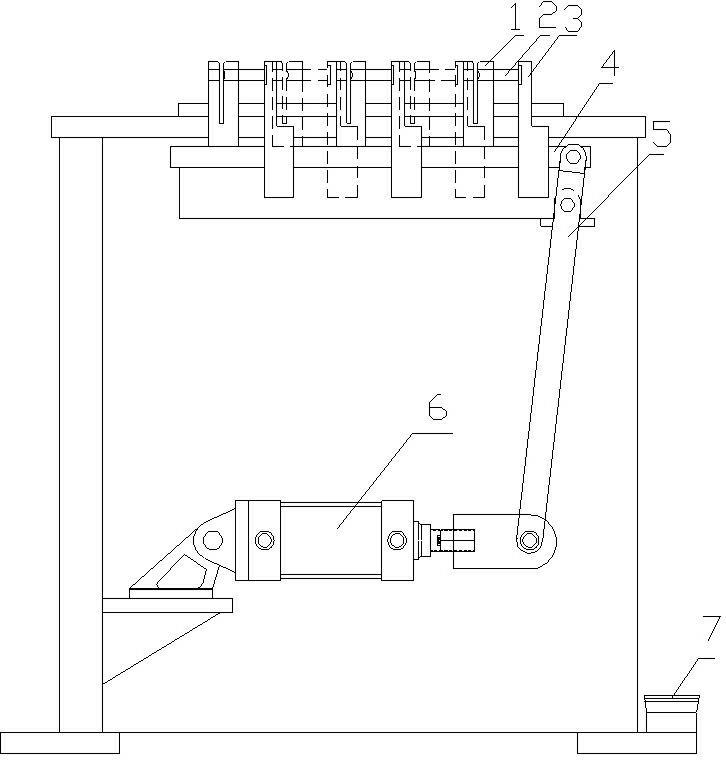

[0009] Such as figure 1 As shown, the punching device includes a frame 7, a cylinder 6, a lever 5, a mold slider 4, a mold moving block 3, a punching knife 2 and a mold fixed block 1, and the cylinder 6 is installed at the bottom of the frame 7, and the cylinder 6 One end of the lever 5 is connected to the piston rod, and the other end of the lever 5 is connected to the mold slider 4. The mold slider 4 is movably installed on the top of the frame 7, and a group of mold movable blocks 3 are installed on the mold slider 4. Each A punching knife 2 is installed on the mold moving block 3, and a group of mold fixing blocks 1 are installed on the top of the frame 7. Guide holes are set on the mold fixing blocks 1, and each guide hole of the mold fixing block 1 corresponds to a punching knife 2 .

[0010] When working, the mold fixing block 1 is installed on the inner wall of the battery case, and the mold slider 4 is pushed by the cylinder 6 through the lever 5, and the mold slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com