VMCPP film with high aluminium layer adhesive force

A technology of adhesion and high aluminum layer, which is applied in the direction of layered products, synthetic resin layered products, flexible coverings, etc., to achieve the effect of improving bonding strength, good affinity, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

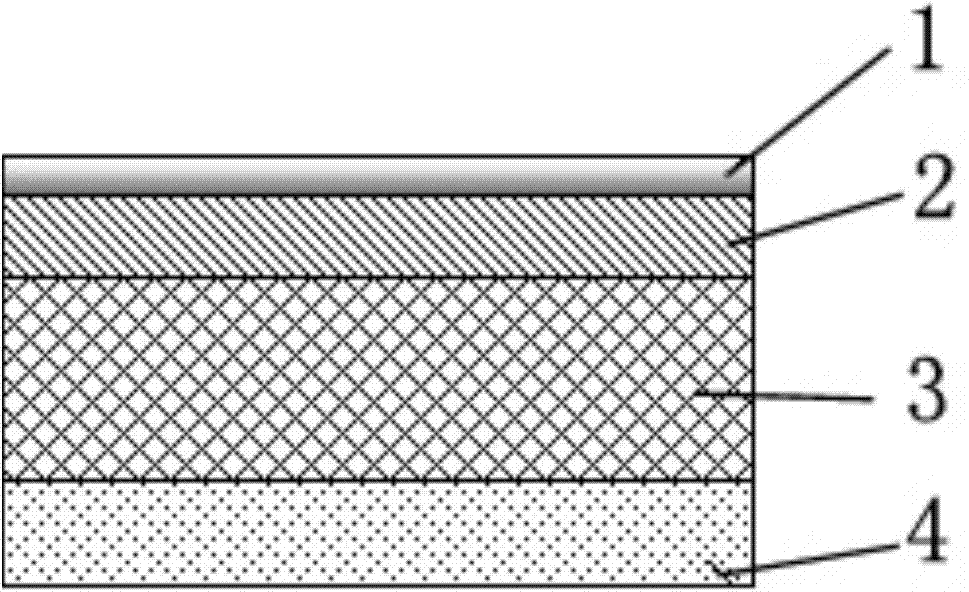

[0014] Such as figure 1 Shown, a kind of VMCPP film of high aluminum layer adhesion, base film adopts three-layer co-extrusion casting method to produce, the three-layer co-extrusion casting film that the present invention has high adhesion to aluminized layer comprises:

[0015] a) Corona layer 2, acrylic polymer and polypropylene blend. Acrylic polymer is preferably ethylene methyl methacrylate copolymer, and polypropylene is preferably binary copolymerized polypropylene.

[0016] b) The middle layer 3, consisting of isotactic homopolypropylene. Isotactic homopolypropylenes containing only antioxidants and chlorine scavengers are particularly preferred.

[0017] c) Heat seal layer 4, composed of polypropylene copolymer. The types of copolymers are: propylene-ethylene copolymer, propylene-butene copolymer, propylene-octene copolymer, pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com