Low-smell vehicle polypropylene composite material and its preparation method

A composite material and polypropylene technology, applied in the field of rubber and plastic materials, can solve the problems that the adsorbent cannot achieve the adsorption effect and the causes are complicated, and achieve the effects of simple manufacturing process, low odor and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

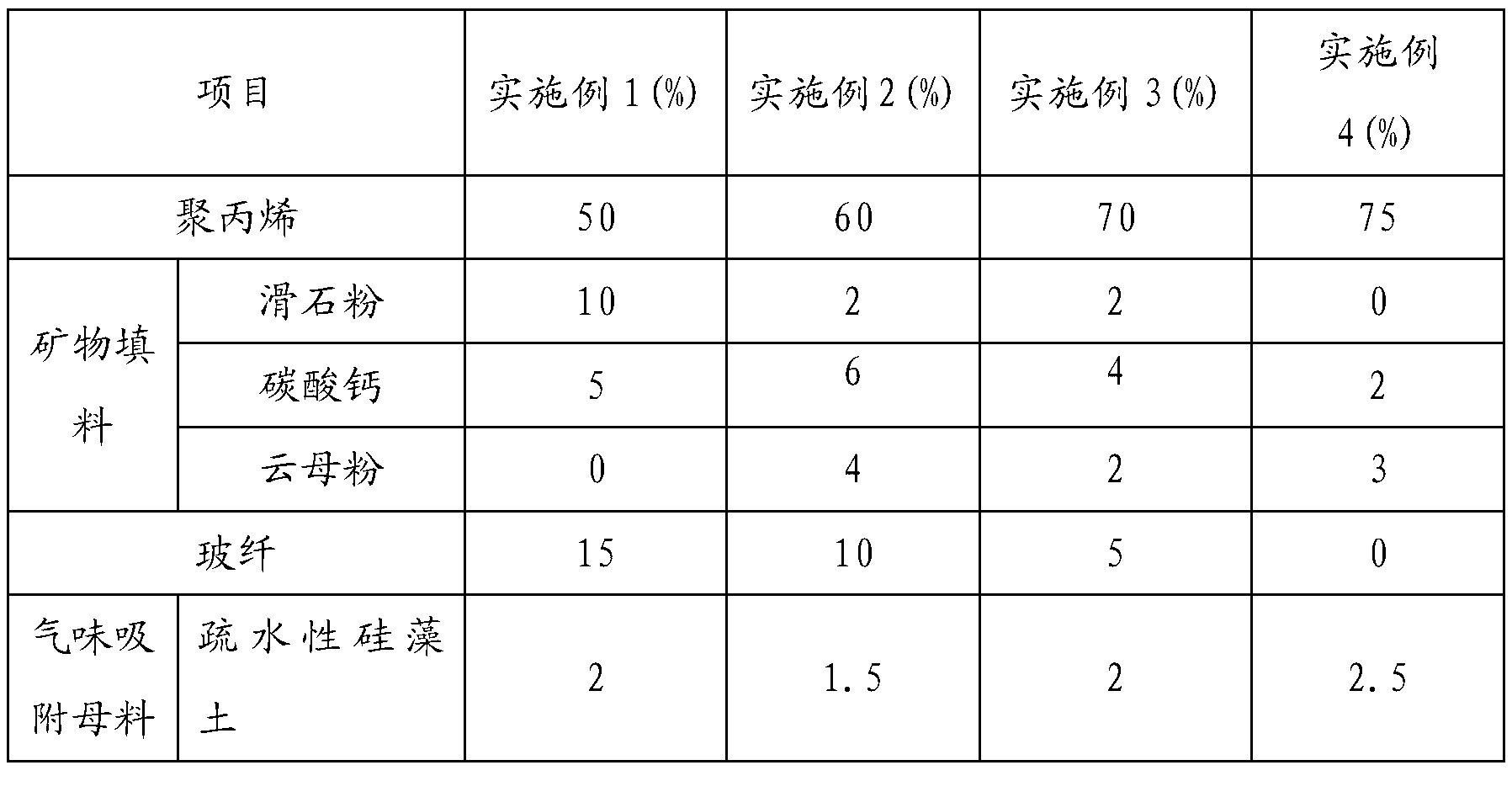

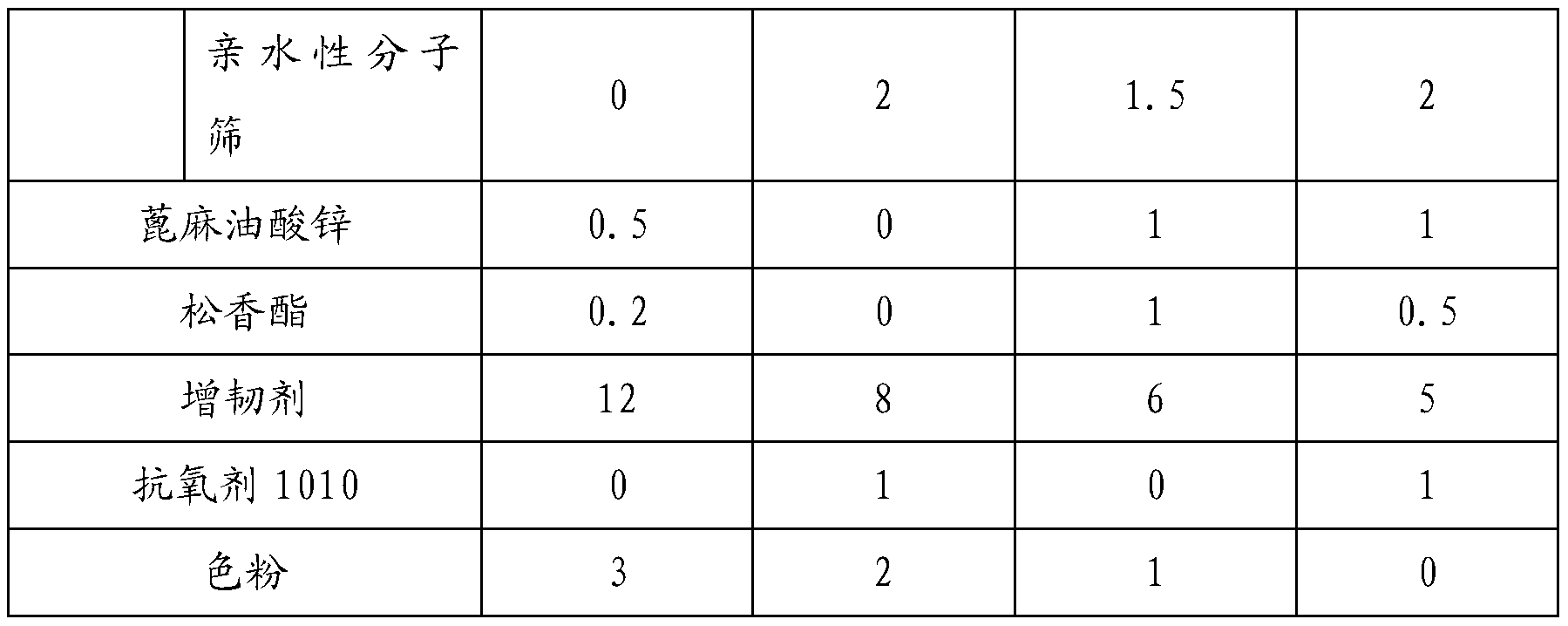

[0026] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in combination with specific implementation methods.

[0027] The preferred embodiment 1 to embodiment 4 in the following table are examples, wherein the ratio is percentage by weight, and other auxiliary agents or ingredients can be added according to actual use:

[0028]

[0029]

[0030] Table I

[0031] The polypropylene is one of copolymerized polypropylene or high crystalline homopolypropylene with a crystallinity of 50% to 70% or a combination thereof, and the mineral filler is one of talcum powder, calcium carbonate or mica powder or Various, the antioxidant 1010 is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester.

[0032] The preparation method of the above-mentioned low-odor automotive polypropylene composite material comprises the following steps:

[0033] 1) Weigh the raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com