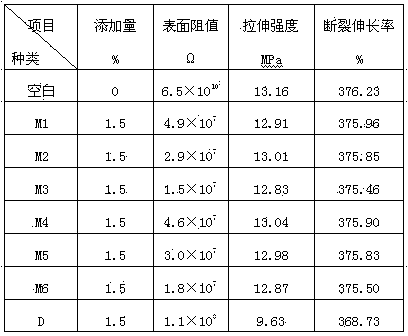

Quaternary ammonium salt hyperbranched antistatic agent and preparation method thereof

A technology of antistatic agent and quaternary ammonium salt, applied in the field of quaternary ammonium salt hyperbranched antistatic agent, preparation of the quaternary ammonium salt hyperbranched antistatic agent, and preparation field of quaternary ammonium salt hyperbranched antistatic agent , to achieve the effect of strong water absorption, low comprehensive cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

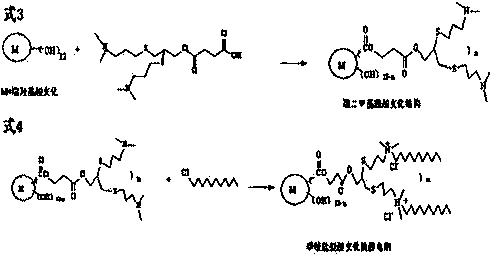

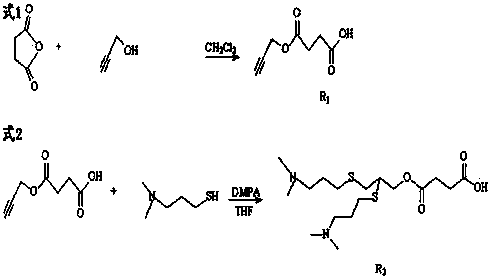

[0041] 1. First prepare the second-generation hydroxyl-terminated hyperbranched G21

[0042] (1) Weigh 9.02g (0.09mol) succinic anhydride, 9.48g (0.09mol) diethanolamine (refluxing and dehydrating before use), first dissolve diethanolamine in 40ml N,N-dimethylacetamide (DMAc), dissolve Then pour it into a three-necked flask equipped with a thermometer, then dissolve succinic anhydride with 40ml of DMAc, then slowly drop it into the three-necked flask, and use a magnetic stirrer to react at 25°C for 2h to obtain AB 2 type monomer;

[0043] (2) Then add 50ml of toluene to the above-mentioned three-necked flask first, then add 1.34g (0.01mol) trimethylolpropane as the nuclear molecule, wait until the trimethylolpropane is completely dissolved, then add 0.15g of sulfamic acid, Stir and heat until there is reflux, separate the generated water with a water separator, stop the reaction after 6 hours of heat preservation, cool down to room temperature, and remove the solvent by rotar...

Embodiment 2

[0049] 1. First prepare the second-generation hydroxyl-terminated hyperbranched G22

[0050] (1) Weigh 9.02g (0.09mol) of succinic anhydride and 4.08g (0.09mol) of diethanolamine (refluxing and dehydrating before use), first dissolve diethanolamine in 40ml of N,N-dimethylacetamide (DMAc), dissolve Then pour it into a three-necked flask equipped with a thermometer and a water separator, then dissolve succinic anhydride with 40ml of DMAc, then slowly drop it into the three-necked flask, and use a magnetic stirrer to react at 25°C for 2 hours to obtain AB 2 type monomer;

[0051] (2) Then add 50mL of toluene to the above-mentioned three-necked flask first, then add 1.34g (0.01mol) trimethylolpropane as the nuclear molecule, wait until the trimethylolpropane is completely dissolved, then add 0.15g of sulfamic acid, Stir and heat until there is reflux, separate the generated water with a water separator, stop the reaction after 6 hours of heat preservation, cool down to room tempe...

Embodiment 3

[0057] 1. First prepare the third-generation hydroxyl-terminated hyperbranched G31

[0058] (1) Weigh 10.51g (0.105mol) of succinic anhydride and 11.04g (0.105mol) of diethanolamine (refluxing and dehydrating before use), first dissolve diethanolamine in 40ml of N,N-dimethylacetamide (DMAc), dissolve Then pour it into a three-necked flask equipped with a thermometer and a water separator, then dissolve succinic anhydride with 40ml of DMAc, then slowly drop it into the three-necked flask, and use a magnetic stirrer to react at 25°C for 3h to obtain AB 2 type monomer;

[0059] (2) Then add 50ml of toluene to the above-mentioned three-necked flask first, then add 0.67g (0.005mol) trimethylolpropane as the nuclear molecule, wait until the trimethylolpropane is completely dissolved, then add 0.18g of sulfamic acid, Stir and heat until there is reflux, separate the generated water with a water separator, react until anhydrous is generated, end the reaction, cool down to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com