Glass fiber reinforced environment-friendly nylon composite material and preparation method thereof

A nylon composite material, environmentally friendly technology, applied in the field of modified polyamide, can solve the problems of poor acid corrosion resistance, low flame retardant efficiency, performance decline, etc., achieve excellent acid resistance and corrosion resistance, improve comprehensive performance, good performance and the effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

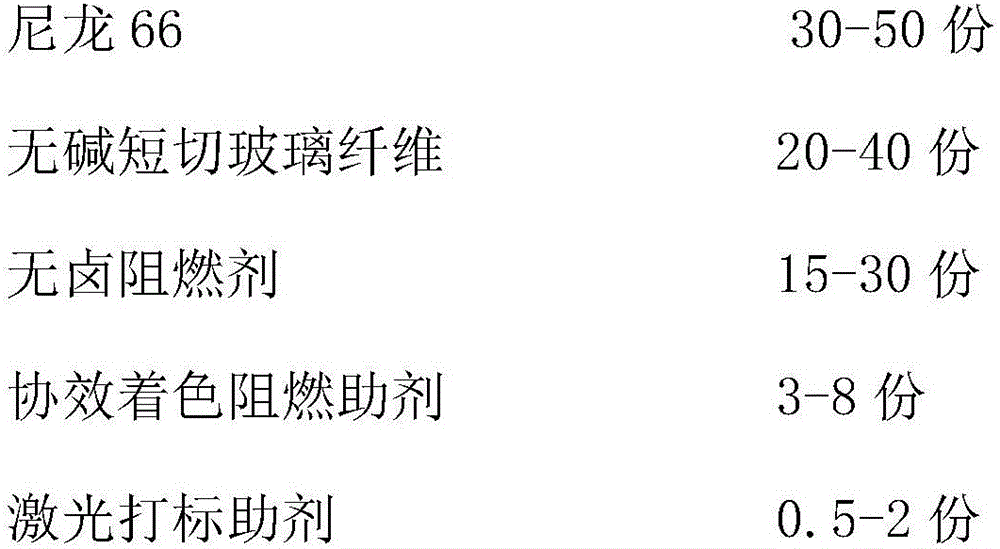

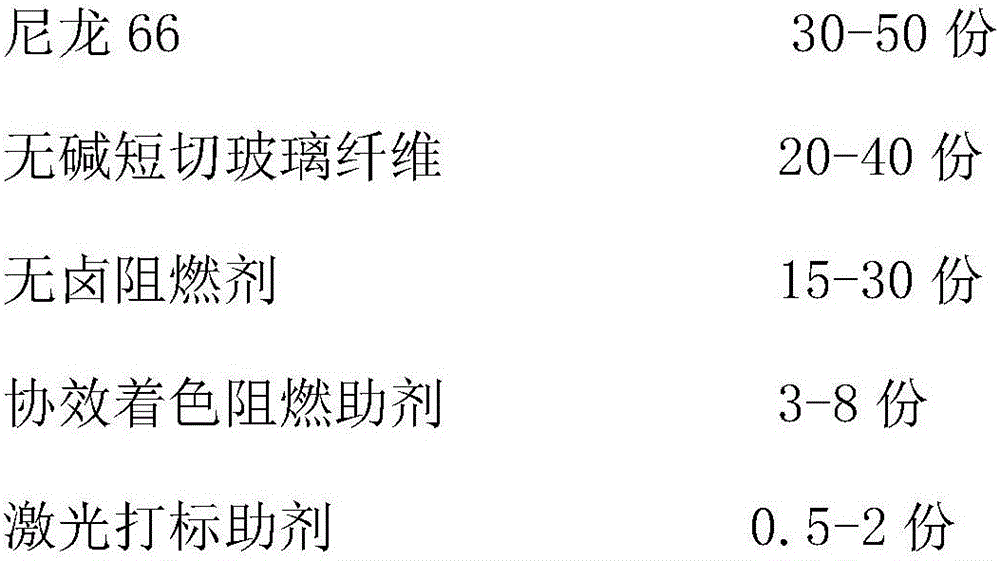

Method used

Image

Examples

Embodiment 1

[0038] The resin intrinsic viscosity of nylon 66 is: 2.3-2.5, 43.7 parts by weight;

[0039] Alkali-free chopped glass fiber: low boron glass fiber with a diameter of 9-11 μm and a length of 4.5 mm, 30 parts by weight;

[0040] Halogen-free flame retardant: melamine cyanurate, 20 parts by weight;

[0041] Synergistic coloring flame retardant additive: composite of magnesium hydroxide and aluminum hydroxide, 5 parts by weight in total according to the weight ratio of 1:1;

[0042] Laser marking aid: metal oxide-coated silicate, 0.5 parts by weight;

[0043] Other additives: silane coupling agent KH560, antioxidant 1098, antioxidant 168 and fatty acid salt, 0.8 parts by weight in total according to the weight ratio of 1:1:1:5.

Embodiment 2

[0045] The resin intrinsic viscosity of nylon 66 is: 2.3-2.5, 48.3 parts by weight;

[0046] Alkali-free chopped glass fiber: low boron glass fiber with a diameter of 9-11 μm and a length of 4.5 mm, 20 parts by weight;

[0047] Halogen-free flame retardant: melamine polyphosphate, 22 parts by weight;

[0048] Synergistic coloring flame retardant additive: composite of magnesium hydroxide and aluminum hydroxide, 8 parts by weight in total according to the weight ratio of 1:1;

[0049] Laser marking aid: metal oxide-coated silicate, 0.5 parts by weight;

[0050] Other additives: silane coupling agent KH560, antioxidant 1098, antioxidant 168 and fatty acid salt, 1.2 parts by weight in total according to the weight ratio of 1:1:1:3.

Embodiment 3

[0052] The resin intrinsic viscosity of nylon 66 is: 2.3-2.5, 43.7 parts by weight;

[0053] Alkali-free chopped glass fiber: boron-free ECR glass fiber with a diameter of 9-11 μm and a length of 3 mm, 30 parts by weight;

[0054] Halogen-free flame retardant: melamine polyphosphate, 22 parts by weight;

[0055] Synergistic coloring flame retardant additive: mica, 3 parts by weight;

[0056] Laser marking aid: metal oxide-coated silicate, 0.5 parts by weight;

[0057] Other additives: silane coupling agent KH560, antioxidant 1098, antioxidant 168 and silicone masterbatch, 0.8 parts by weight in total according to the weight ratio of 1:1:1:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com