High temperature and high voltage resistant cable

A high temperature and high resistance technology, applied in the field of high temperature and high voltage resistant cables, can solve the problems of life and property safety hazards, damage to the cable protective layer, easy aging and cracking, etc., to improve insulation performance and high voltage resistance, The effect of preventing the spread of flames and increasing the intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

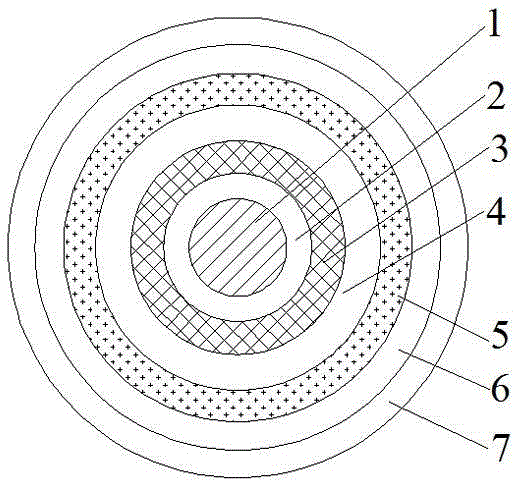

[0029] The high temperature and high voltage resistant cable of the present invention comprises a conductor (i.e. an oxygen-free copper rod 1) and a sheath layer wrapped outside the conductor, the sheath layer is successively an insulating layer 2, a mica tape layer 3, Low-smoke, halogen-free, flame-retardant polyolefin inner sheath 4, braided shielding layer 5, low-smoke, halogen-free, flame-retardant polyolefin outer sheath 6, outer sheath 7, insulation layer 2 and outer sheath 7 are all used for cables Modified fluoroplastics.

[0030] In this example, the composition of modified fluoroplastics for cables is 60 parts of polytetrafluoroethylene, 10 parts of molybd...

Embodiment 2

[0035] Embodiment 2 of the high temperature and high voltage resistant cable of the present invention, the main technical solution of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment adopt the explanation in Embodiment 1, and will not be repeated here repeat. The difference between this example and example 1 is that the composition of modified fluoroplastics for cables is 80 parts of polytetrafluoroethylene, 20 parts of molybdenum disulfide, 4 parts of magnesium hydroxide, 6 parts of trioctyl phosphate, and 6 parts of long glass fibers. , 10 parts of dioctyl sebacate, 9 parts of calcium carbide, 3 parts of bisphenol, 3 parts of paraffin oil, 0.2 parts of anti-rodent masterbatch, 0.2 part of anti-rat masterbatch.

Embodiment 3

[0037] Embodiment 3 of the high temperature and high voltage resistant cable of the present invention, the main technical solution of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment adopt the explanation in Embodiment 1, and will not be repeated here repeat. The difference between this example and example 1 is that the composition of modified fluoroplastics for cables is 70 parts of polytetrafluoroethylene, 15 parts of molybdenum disulfide, 4 parts of magnesium hydroxide, 4 parts of trioctyl phosphate, and 5 parts of long glass fibers. , 7 parts of dioctyl sebacate, 7 parts of calcium carbide, 2 parts of bisphenol A, 2 parts of paraffin oil, 0.1 part of anti-rat masterbatch, 0.1 part of anti-termite masterbatch.

[0038] The experimental data of the above three embodiments are shown in Table 1.

[0039] The comprehensive performance index of the high temperature and high voltage resistant cable of the present invention is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com