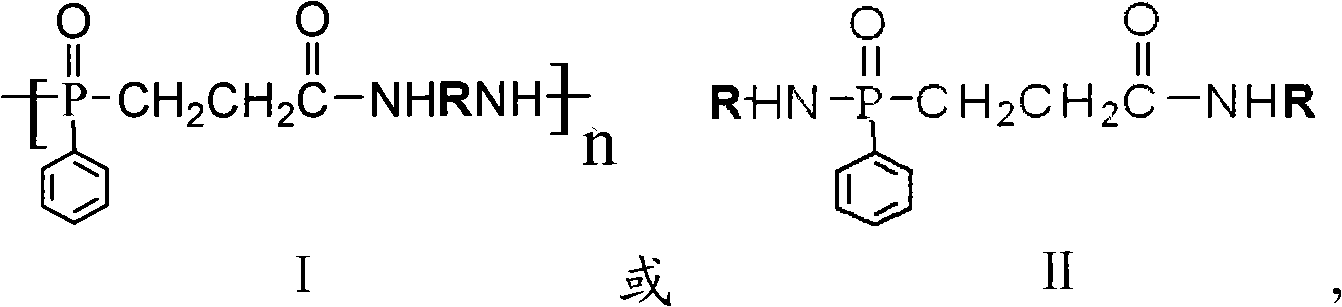

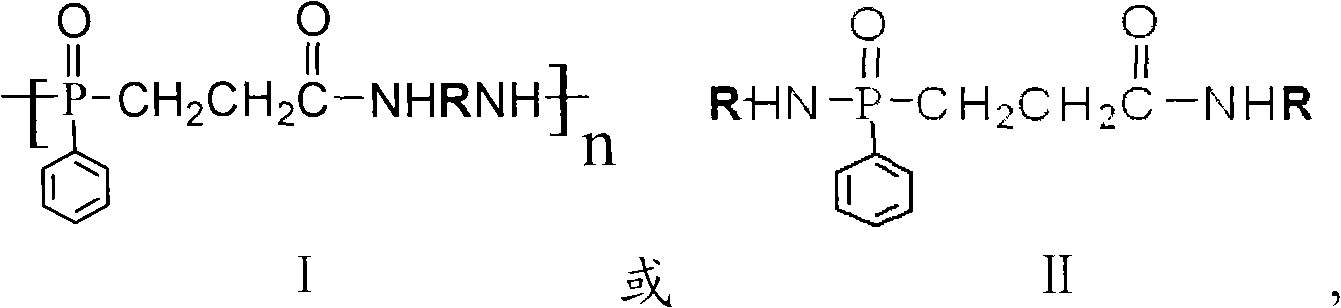

P-N collaborative type flame-retardant compound and preparation method thereof

A compound, P-N technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problems of restricting the development of the flame retardant material industry, starting late, etc. The effect of simple control and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

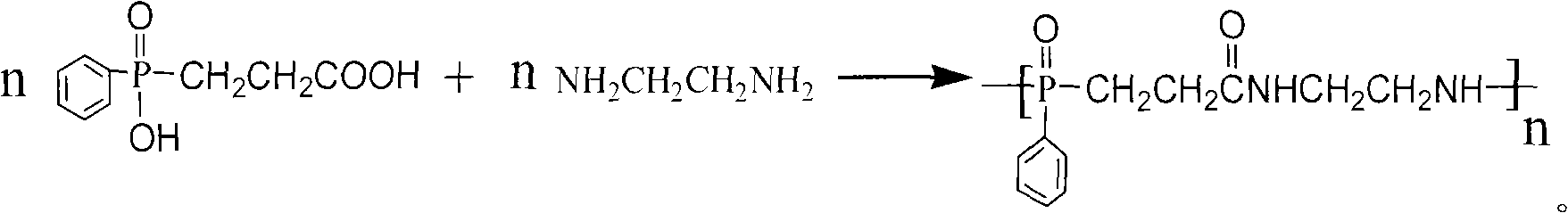

Embodiment 1

[0031] In a 250ml three-neck flask equipped with a stirrer and a water separator, after nitrogen protection, add 0.1mol carboxyethylphenylphosphinic acid and 0.1mol ethylenediamine, and add 150ml o-dichlorobenzene, stir, slowly Raise the temperature of the reaction system to 135°C, maintain the temperature for 3 hours, continue to raise the temperature to 160°C for 3 hours, remove the reaction water, and then cool the mixed reaction system to solidify, grind and wash the solid with acetone, suction filter, and filter the residue through The target P-N synergistic flame retardant compound is formed by vacuum drying, the yield rate is 95%, the melting temperature of the product is 190±10°C, and the decomposition temperature is 230±5°C. Its process route is:

[0032]

Embodiment 2

[0034] In a 250ml three-neck flask equipped with a stirrer and a water separator, after nitrogen protection, add 0.1mol carboxyethylphenylphosphinic acid and 0.1mol ethylenediamine, and add 150ml high boiling point solvent oil, stir, slowly Raise the temperature of the reaction system to 140°C, maintain the temperature for 4 hours, then continue to raise the temperature to 155°C for 4 hours to remove the reaction water, then cool the mixed reaction system to solidify, grind and wash the solid with ether, filter with suction, and filter the residue through The target P-N synergistic flame retardant compound was formed by vacuum drying, the yield rate was 94%, the melting temperature of the product was 190±10°C, and the decomposition temperature was 230±5°C.

Embodiment 3

[0036] In a 250ml three-necked flask equipped with a stirrer and a water separator, after nitrogen protection, add 0.1mol carboxyethylphenylphosphinic acid and 0.1mol ethylenediamine, add 150ml xylene, stir, and slowly raise the temperature Reflux at 140°C for 8 hours to remove the reaction water, then cool and solidify the mixed reaction system, grind and wash the solid with ethyl acetate, filter with suction, and vacuum-dry the filter cake to form the target P-N synergistic flame retardant compound. The yield is 93%, the melting temperature of the product is 190±10°C, and the decomposition temperature is 230±5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com