High-concentration polyolefin calcium carbonate filled white master batch and preparation method thereof

A technology of polyolefin calcium carbonate and white masterbatch, which is applied in the field of plastic coloring, can solve the problems of insufficient polyolefin compatibility, poor dispersibility, and many crystal points, and achieves low cost, strong covering ability and high whiteness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, preparation 1000g high concentration polyolefin calcium carbonate fills white masterbatch

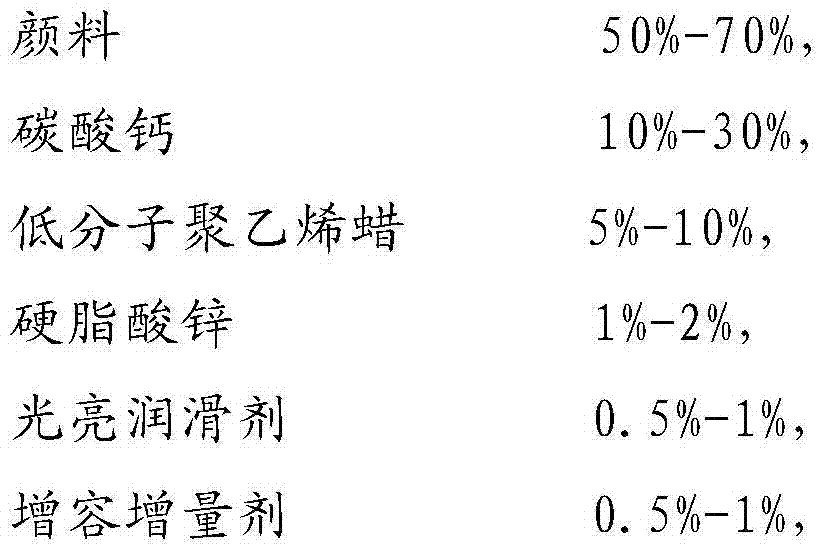

[0021] 1. The weight of each component is:

[0022]

[0023]

[0024] 2. Preparation method:

[0025] First, add the low-molecular polyethylene wax, zinc stearate, bright lubricant, compatibilization extender, nano-calcium carbonate and carrier resin in the pigment and plastic additives into the high-mixer at a speed of 600 rpm and mix for 15 minutes. Minutes; then add the mixture of coupling agent and liquid paraffin, and then stir at high speed for 10 minutes; finally extrude the above-mentioned mixed material into the Songwu twin-screw extruder, cool, dry, and cut into pellets to make filled white masterbatch.

Embodiment 2

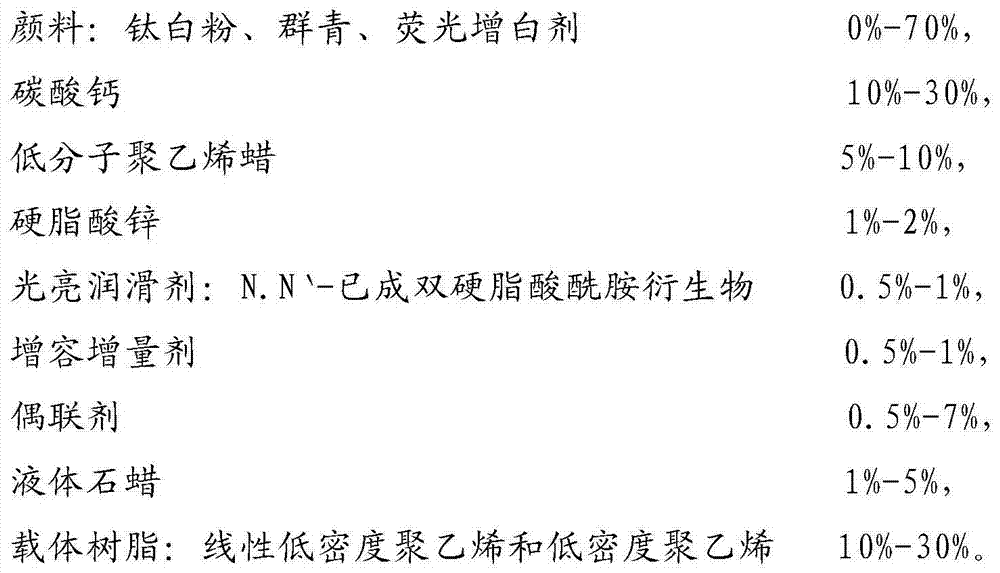

[0026] Embodiment 2, prepare the weight of each component of 1000g high concentration polyolefin calcium carbonate filling masterbatch:

[0027]

[0028] 2. Preparation method:

[0029] First, add the low-molecular polyethylene wax, zinc stearate, bright lubricant, compatibilization extender, nano-calcium carbonate and carrier resin in the pigment and plastic additives into the high-mixer at a speed of 600 rpm and mix for 15 minutes. Minutes; then add the mixture of coupling agent and liquid paraffin, and then stir at high speed for 10 minutes; finally extrude the above-mentioned mixed material into the Songwu twin-screw extruder, cool, dry, and cut into pellets to make filled white masterbatch.

Embodiment 3

[0030] Embodiment 3, prepare the weight of each component of 1000g high concentration polyolefin calcium carbonate filling masterbatch:

[0031]

[0032] 2. Preparation method:

[0033] First, add the low-molecular polyethylene wax, zinc stearate, bright lubricant, compatibilization extender, nano-calcium carbonate and carrier resin in the pigment and plastic additives into the high-mixer at a speed of 600 rpm and mix for 15 minutes. Minutes; then add the mixture of coupling agent and liquid paraffin, and then stir at high speed for 10 minutes; finally extrude the above-mentioned mixed material into the Songwu twin-screw extruder, cool, dry, and cut into pellets to make filled white masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com