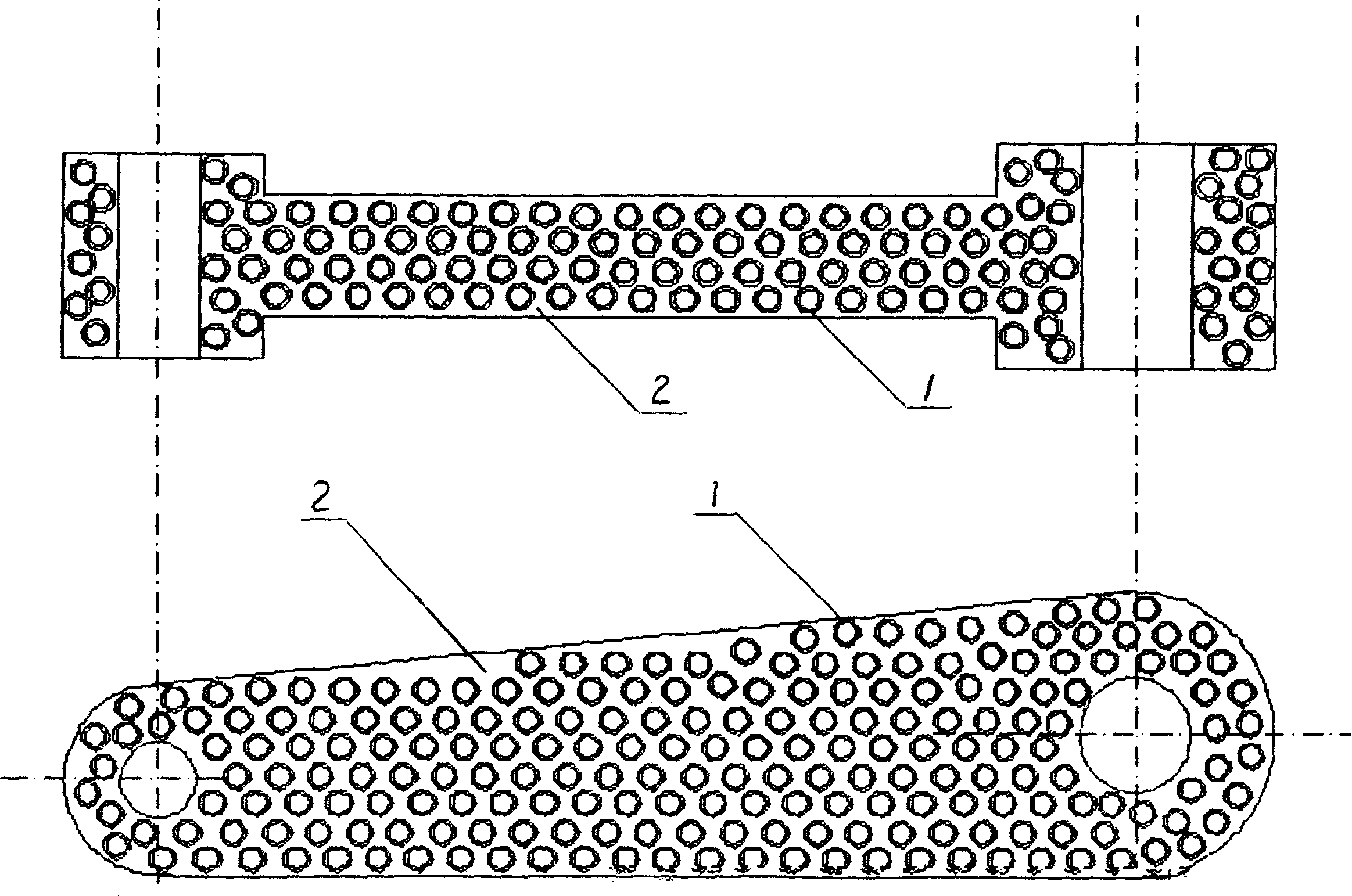

Close-pore foamed metal element with hollow ceramic and method for preparing the same

A technology of closed-cell foam and metal foam, which is applied to heat exchange equipment, rotors, cylinders, etc., can solve problems such as complex processes, and achieve the effects of simplified processes, uniform microstructure, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] 1. Make a mold according to the shape required for the purpose of the aluminum foam. Metal aluminum is melted to obtain aluminum liquid (the melting point of metal aluminum is 660° C.). Preheat the hollow diatomaceous earth ceramic ball to about 655°C. Add 75vt% hollow diatomite ceramic balls to the molten aluminum under stirring, continue to stir and slowly cool down to about 650°C, pour the mixed aluminum liquid into a mold, and obtain hollow diatomite ceramic balls after cooling and molding Closed-cell aluminum foam.

[0019] 2. Make molds. Melting iron (steel) yields liquid iron (steel). Preheat the hollow alumina ceramic balls to near the melting point of iron (steel), add 35vt% hollow alumina ceramic balls under stirring, then add 0.3wt% metal calcium or magnesium, stir evenly, and mix the iron (steel) The liquid is poured into the mold, and after cooling and forming, a hollow alumina ceramic ball closed-cell foam iron (steel) piece is obtained.

[0020] 3. M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume percentage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com