T-shaped double arc welding backing process for medium-thickness plate

A thick plate and process technology, which is applied in the field of T-shaped double-arc welding backing process for medium and thick plates, can solve the problems of low work efficiency, high cost, poor construction environment, etc., and achieve the effect of reducing production costs and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

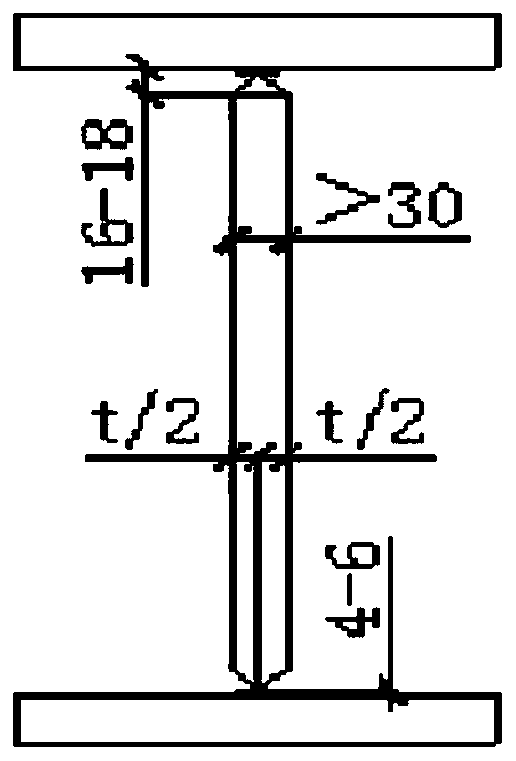

[0034] (1) H steel web blanking, groove allowance 3mm-5mm, double-sided K-shaped groove for full penetration welds with H steel web greater than 16mm, groove width 16mm-18mm, no groove left For blunt edges, leave a gap of 4mm-6mm, and use backing plates of uniform thickness for components of the same batch.

[0035] (2) Impurities such as cut slag, scale, rust and other impurities within 50mm on both sides of the K-shaped groove position of the H steel web and the full penetration weld position in the middle of the flange are polished clean and have a metallic color.

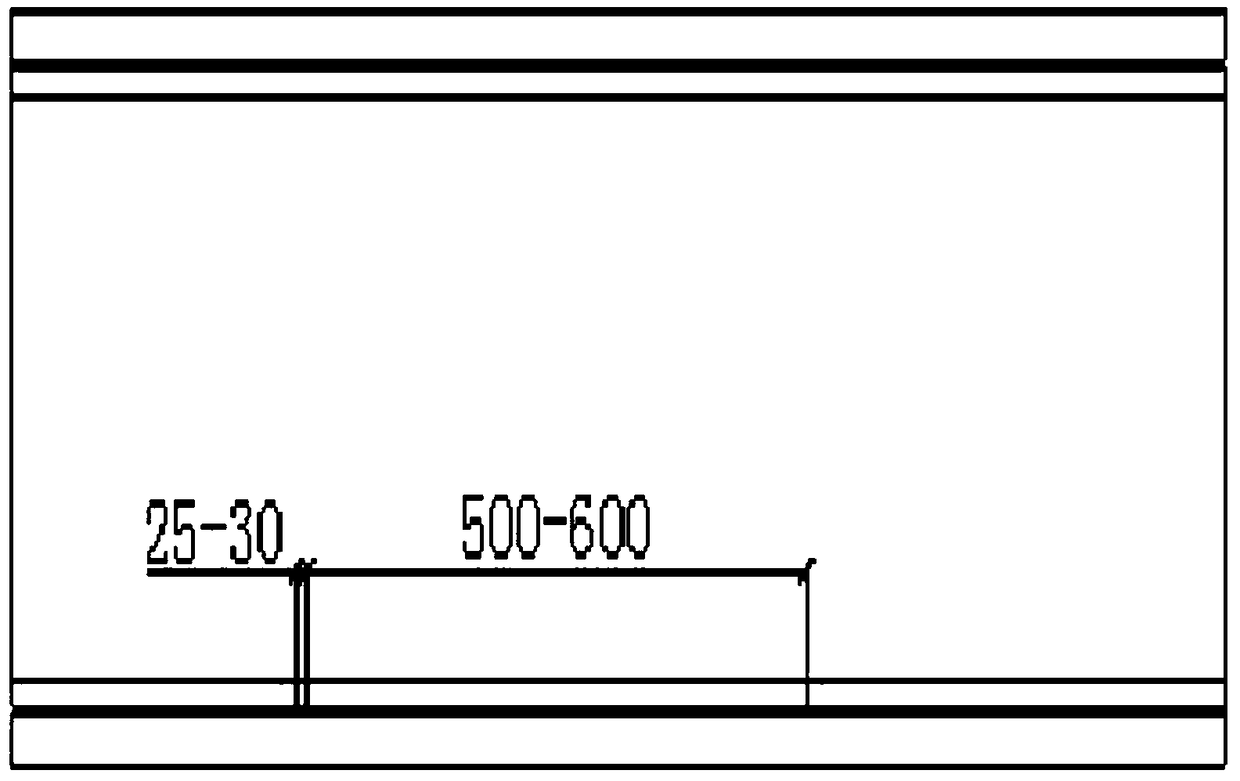

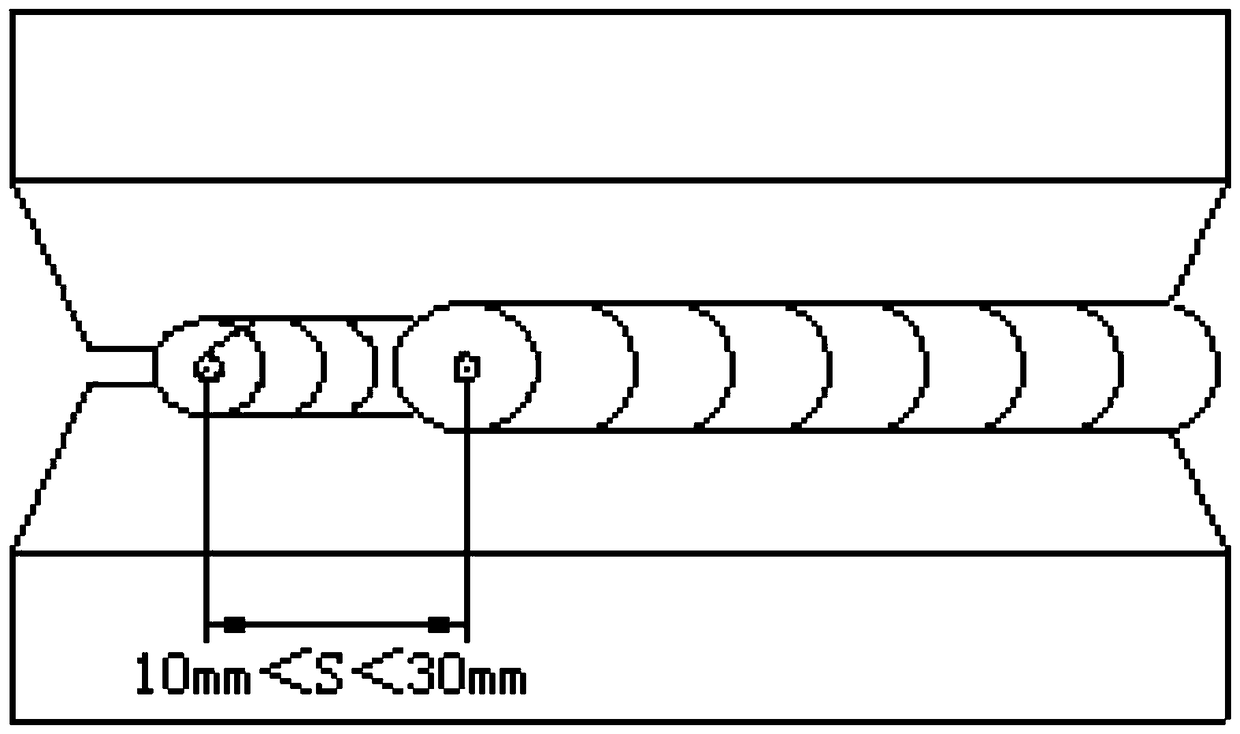

[0036] (3) When the polished H steel web is welded with double-arc bottoming, the gap of the full penetration weld is 4.5mm immediately, and a 5mm backing plate is used to control the gap every 500mm-600mm, and the positioning welding point is at The location within 10mm of the backing plate, the spacing of the tack welding is consistent with the spacing of the backing plate, the interval is 500mm-600mm, and the...

Embodiment 2

[0045] (1) H steel web blanking, groove allowance 3mm-5mm, double-sided K-shaped groove for full penetration welds with H steel web greater than 16mm, groove width 16mm-18mm, no groove left For blunt edges, leave a gap of 4mm-6mm, and use backing plates of uniform thickness for components of the same batch.

[0046](2) Impurities such as cut slag, scale, rust and other impurities within 50mm on both sides of the K-shaped groove position of the H steel web and the full penetration weld position in the middle of the flange are polished clean and have a metallic color.

[0047] (3) When the polished H steel web is subjected to double-arc bottoming welding, a gap of 5mm is left when the full penetration weld is assembled, and a 5mm backing plate is used to control the gap every 500mm-600mm, and the positioning solder joints are placed on the backing The position within 10mm of the plate, the spacing of the tack welding is consistent with the spacing of the backing plate, the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com