Metallic effect printing ink with infrared characteristic

A metal effect, ink technology, applied in inks, household appliances, applications, etc., can solve the problems of reduced ink flicker, no reports or applications, weakening the public anti-counterfeiting properties of ink, etc., to achieve the effect of improving the difficulty of counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Engraving gravure metallic effect ink

[0049] Ink formula (weight%):

[0050]

[0051]

[0052] The above-mentioned effect pigments include 30% effect pigments coated with glass as a substrate, 40% effect pigments coated with aluminum oxide as a substrate, and 30% effect pigments coated with mica as a substrate. The infrared regulator is antimony-doped tin oxide coated with mica.

[0053] The preparation process of the ink is as follows: first, the binder, nano-silica, wax and dodecylbenzenesulfonate are rolled into base oil; then 3,4,13,14-tetracarboximide bisperylene , infrared regulator, phthalocyanine green and the base oil are mixed and rolled to form a base ink; finally, the base oil, base ink, effect pigment and desiccant are fully mixed by high-speed stirring to form the ink.

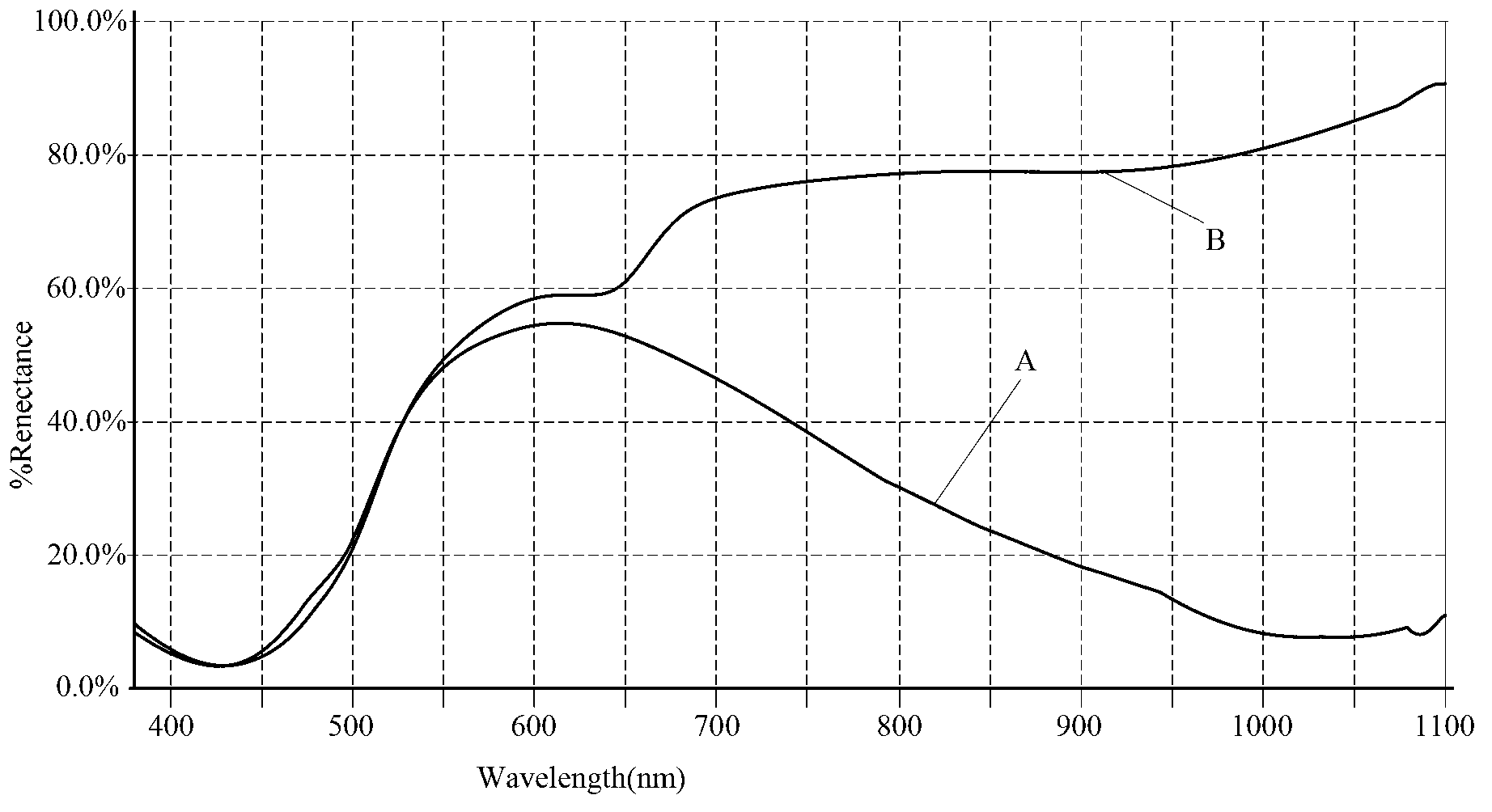

[0054] The infrared absorbing material used in the ink is bisperylene tetracarboximide, the maximum absorption peak is located near 780nm, the covering power is 37%, t...

Embodiment 2

[0056] Example 2: UV screen metal effect ink

[0057] Ink formula (weight%):

[0058]

[0059]

[0060] The infrared regulator is mica-coated antimony-doped tin oxide. The infrared absorbing material used in this ink is 4,4',4"-tris(p-dibutyronitrileamino)triphenylamine hexafluoroantimonic acid, and the maximum absorption peak is located near 980nm. Hiding power is 28%, and the addition amount in ink is 2%, makes described screen printing ink according to the method similar to embodiment 1, and the infrared reflectance of ink is 28% now, and the flickering value of printed matter of ink is 4.1, It meets the needs of use, but the physical and chemical resistance of the ink prints, light fastness and solvent resistance are both reduced, it is recommended to be used in products or environments that have a short retention time, or are protected from light and organic solvents.

Embodiment 3

[0062] The ink components are the same as in Example 2, but the infrared absorbing material (4,4',4"-tris(p-dibutyronitrileamino)triphenylamine hexafluoroantimonic acid) used has been coated in advance, the method is as follows: 25g Dissolve urea in 60g of 37% formaldehyde solution, use triethanolamine to adjust pH=8.5, then heat to 75°C, and react for 1h under stirring. Add 0.5g of nonylphenol polyoxyethylene ether and 20g of 4,4',4"-tri( For p-dibutyronitrile amino)triphenylamine hexafluoroantimonic acid, stir vigorously for 5 minutes, use hydrochloric acid to adjust PH=3.5, heat to 60°C, react for 2 hours, then wash, filter and dry to obtain the infrared absorbing material modified by coating with urea-formaldehyde resin.

[0063] Compared with Example 2, the screen printing ink in this example has similar metallic color and infrared features, but after using the modified infrared absorbing material, the light fastness and solvent resistance of the ink printed product are si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com