Multi-layered anti-counterfeit label and production method and multi-layered anti-counterfeit indication method thereof

An anti-counterfeiting label, multi-level technology, applied in the directions of stamps, instruments, identification devices, etc., can solve the problems of anti-counterfeiting label products and anti-counterfeiting methods without pre-deformation and recovery characteristics, and achieve flexible and convenient implementation, cost reduction, and reliable results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

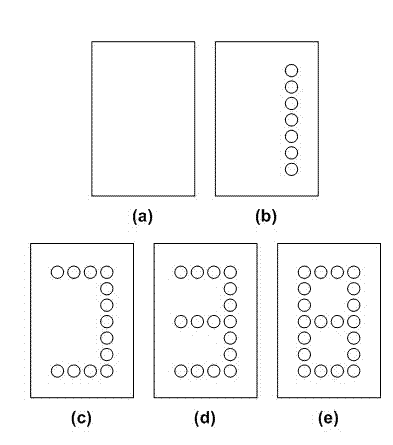

[0029] Embodiment 1: A multi-level anti-counterfeiting indication method, which utilizes the thermally induced shape memory properties of shape memory polymers, and after thermodynamic pre-deformation treatment, the morphology of the polymers gradually changes accordingly during the gradual heating process. Features are made into labels to identify the authenticity of the item.

[0030] The thermally induced shape memory effect of the thermally induced shape memory polymer is significant: the residual deformation of the polymer after thermodynamic processing is higher than 5%; the shape recovery rate is higher than 5%. The thermotropic shape memory polymer is a pure polymer or a polymer-based composite material.

[0031] A thermotropic shape memory polymer of a certain size is used as the substrate of the label, and is subjected to multiple pre-deformation treatments at a temperature higher than the initial temperature of its glass transition or melting transition to make a fi...

Embodiment 2

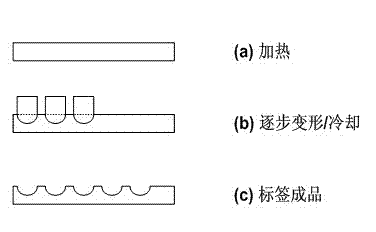

[0034] Embodiment 2: Taking epoxy polymer as the matrix, the process of preparing anti-counterfeiting labels with non-overlapping pre-deformation is as follows figure 1 As shown, the following process steps are included:

[0035] Heat the label to 70°C;

[0036] pressed on its surface as figure 1 (b) Indentations shown (maximum diameter of the indentation is 5 mm, depth is 2 mm, and the distance between each indentation is 10 mm);

[0037] Lower the temperature to 60°C, and press out more indentations on different areas of its surface;

[0038] Cool to room temperature. get as figure 1 (c) Finished label shown.

Embodiment 3

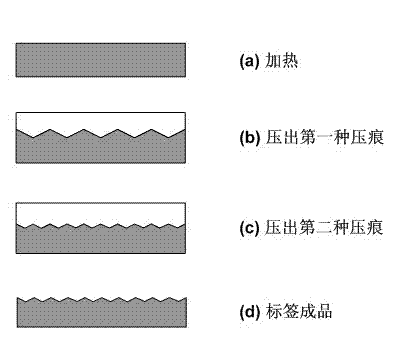

[0039] Example three: the process of preparing an anti-counterfeit label with overlapping pre-deformation is as follows: figure 2 As shown, the following process steps are included:

[0040] Heat the label to 70°C;

[0041] Extrude such as figure 2 (b) the first type of indentation shown;

[0042] Lower the temperature to 60°C, and use another mold with another pattern to extrude in the same area such as figure 2 (c) The second type of indentation shown;

[0043] down to room temperature to obtain figure 2 (d) Finished label shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com