Random die-cutting type anti-counterfeiting structure, laser die cutter, die cutting method and anti-counterfeiting method

A laser die-cutting and die-cutting technology, applied in the field of anti-counterfeiting, can solve the problems of restricting the development of anti-counterfeiting technology, achieve the effect of improving product value and application range, meeting market requirements, and improving anti-counterfeiting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

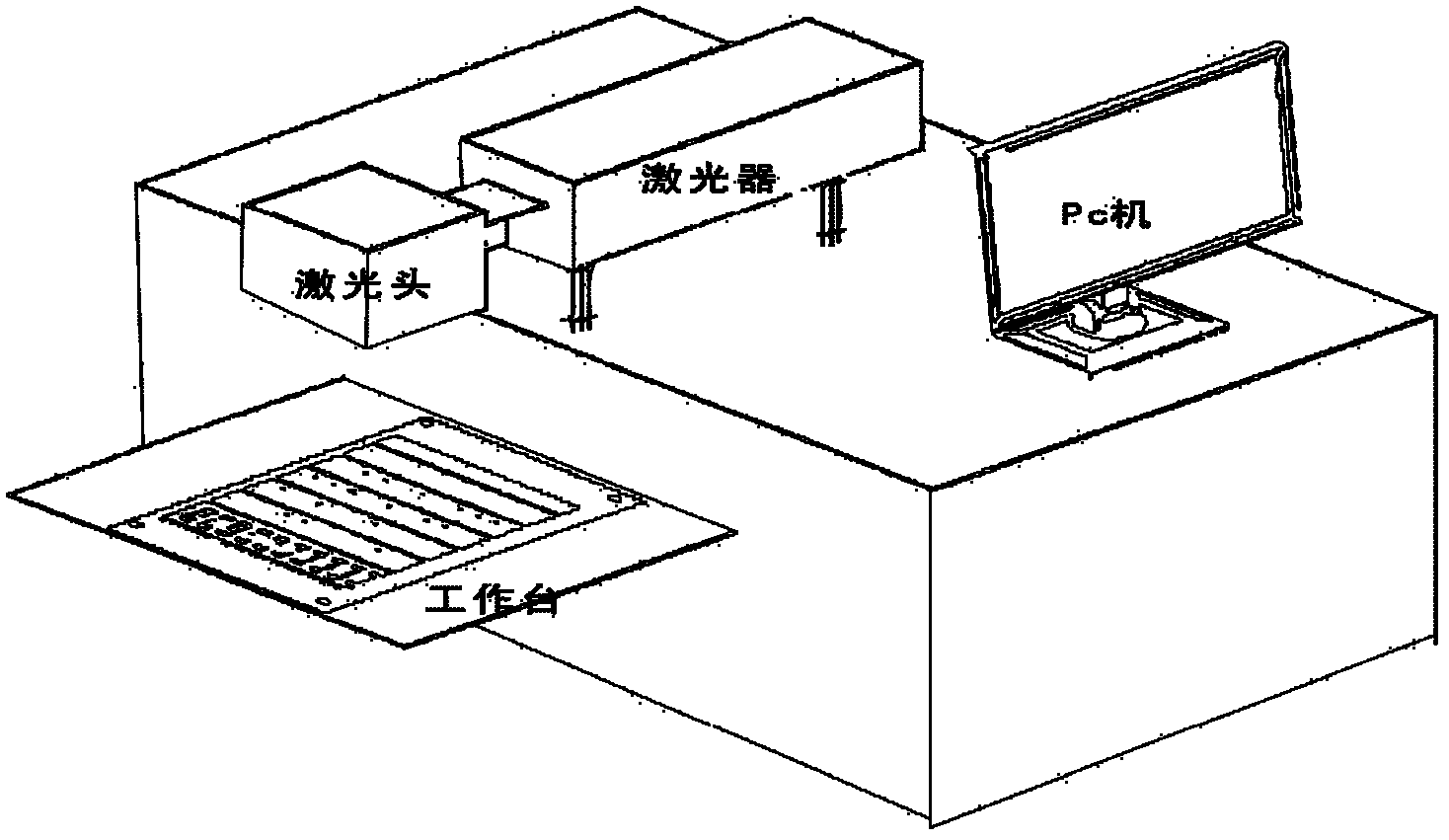

[0047] In order to facilitate an accurate and thorough understanding of the corresponding technical solutions of the present invention, the anti-counterfeiting structure, anti-counterfeiting method, laser die-cutting machine and die-cutting method of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

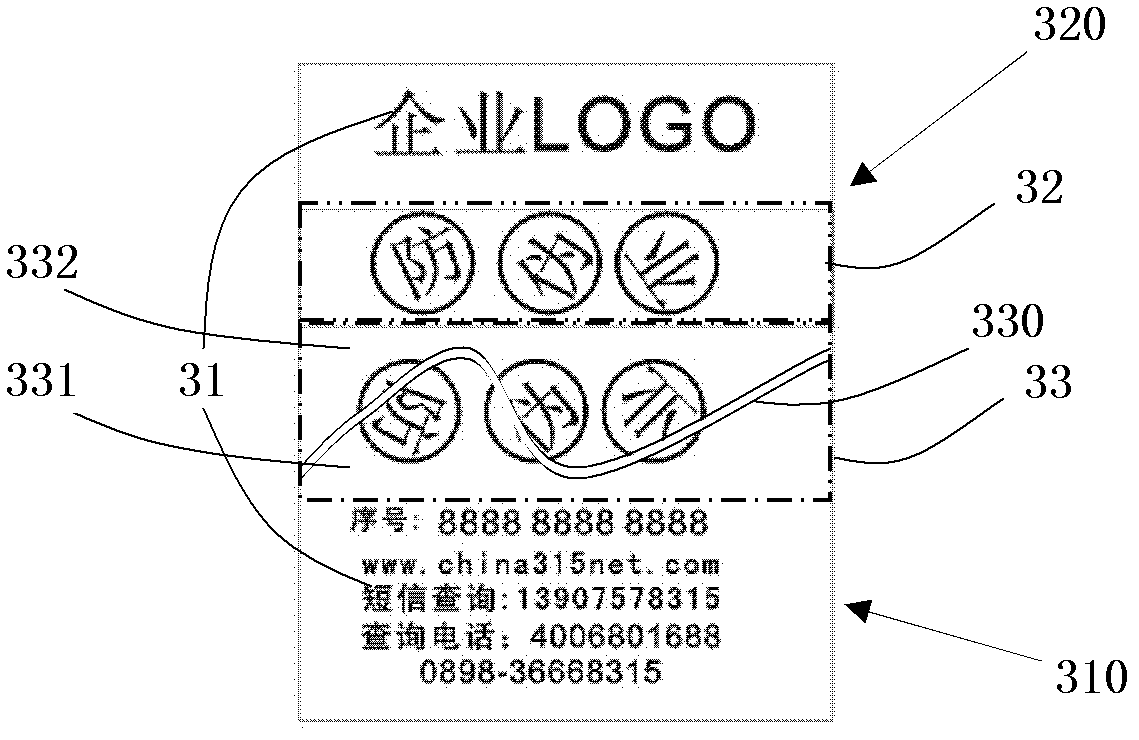

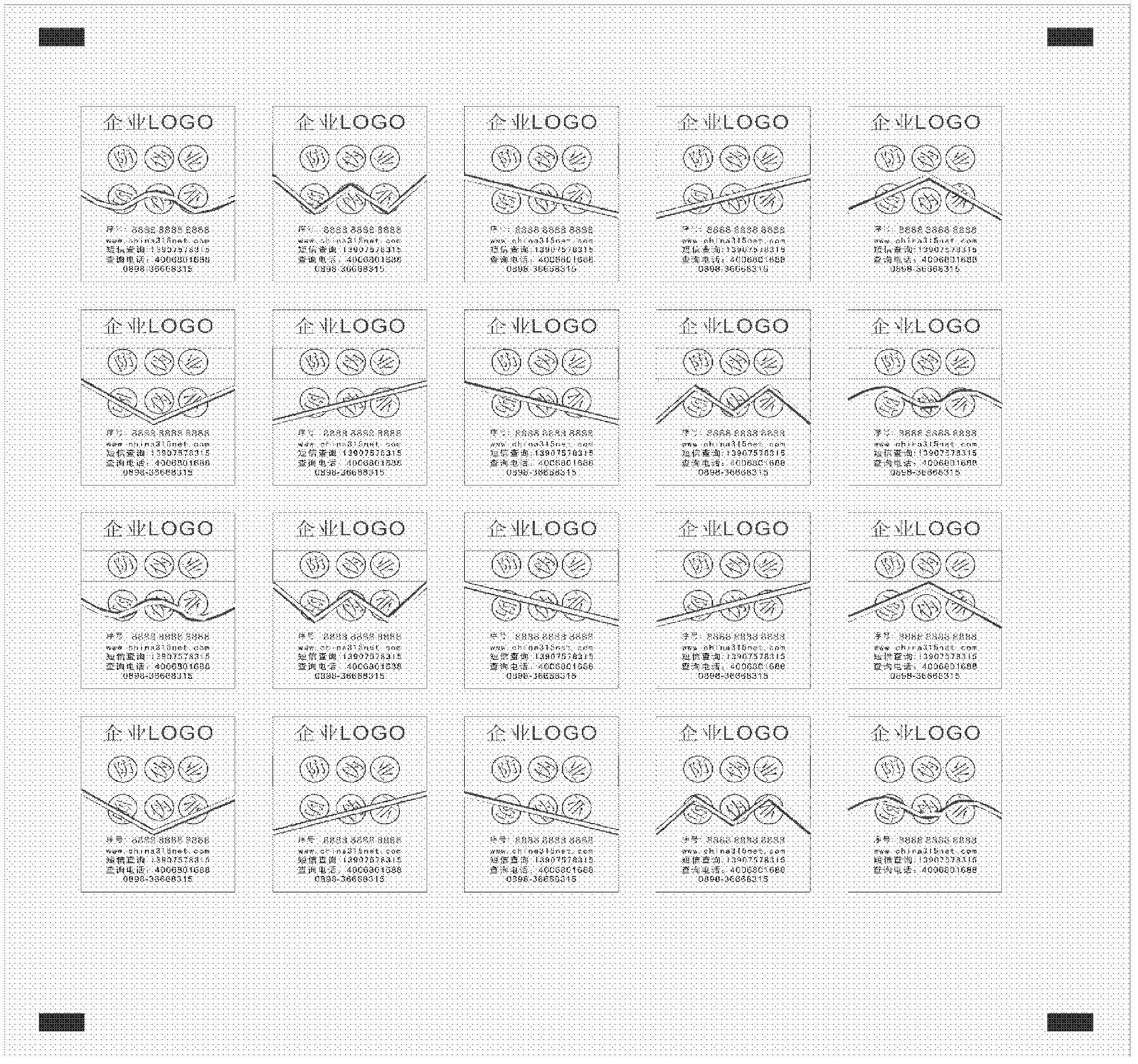

[0048] The present invention first proposes a random die-cut anti-counterfeit structure, which includes a query information area, a result check area and a random cutting area, the query information area includes serial numbers and anti-counterfeit query information, and the result check area is provided with a query Text anti-counterfeiting features, the random cutting area is provided with inverse text anti-counterfeiting features, and is divided into query attachment parts and verification attachment parts according to randomly generated die cutting lines, and then die-cuts the anti-counterfeiting structure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com